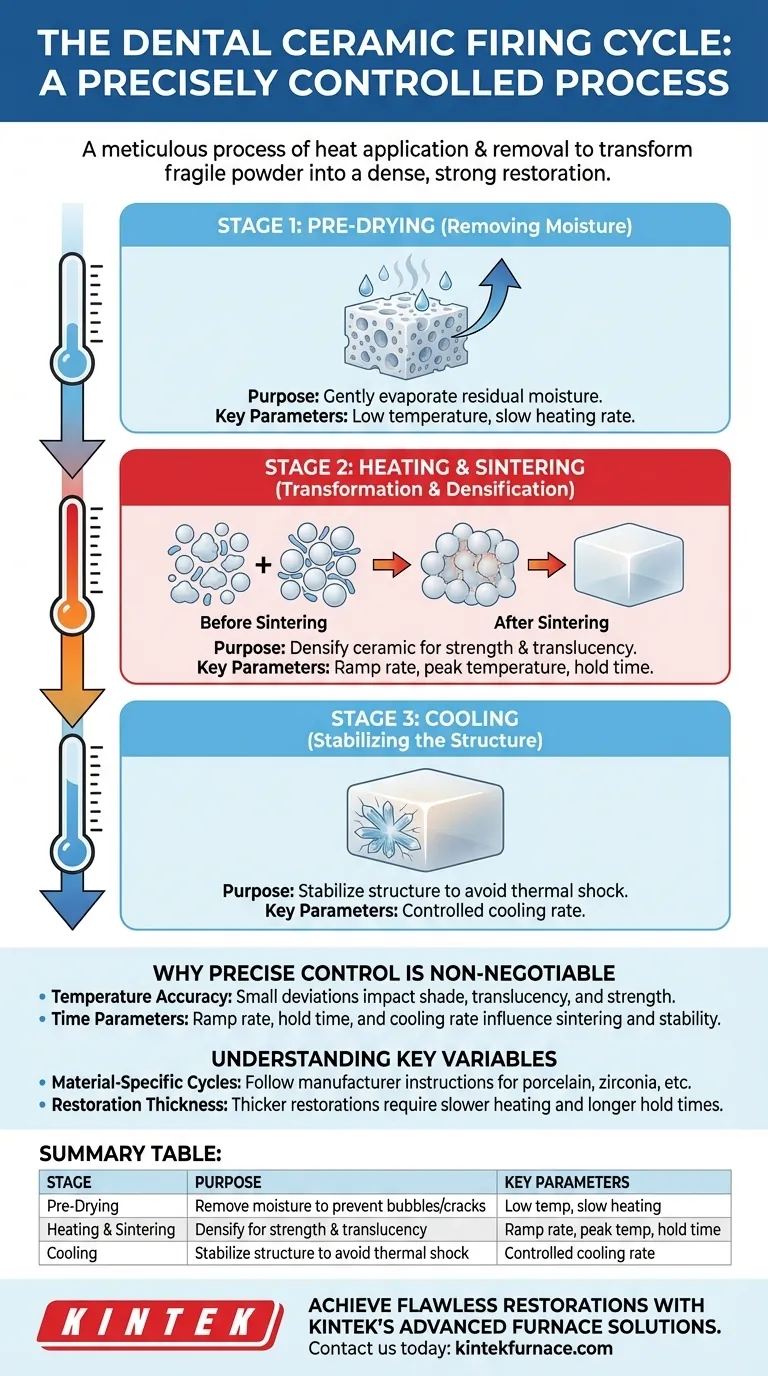

In essence, the dental ceramic firing cycle is a precisely controlled process of heat application and removal. It consists of three primary stages: a low-temperature pre-drying phase, a high-temperature heating and sintering phase, and a controlled cooling phase. Each stage has a specific purpose, and the exact time and temperature parameters are dictated by the specific ceramic material being used and the desired final properties of the restoration.

The firing cycle is not merely about heating something up; it is a meticulous metallurgical process designed to transform a fragile ceramic powder into a dense, strong, and aesthetically pleasing dental restoration by systematically controlling its physical and chemical changes.

The Purpose of Each Stage in the Firing Cycle

To achieve a successful restoration, one must understand that each stage performs a critical and distinct function. Skipping or rushing a stage will compromise the final integrity of the ceramic.

Stage 1: Pre-Drying (Removing Moisture)

The cycle begins with a slow, low-temperature heating phase known as pre-drying. This typically occurs just below or at the boiling point of water.

The sole purpose of this stage is to gently and completely evaporate any residual moisture from the built-up ceramic. If heated too quickly, this moisture would turn to steam and create bubbles, voids, or even cracks within the restoration.

Stage 2: Heating and Sintering (Transformation and Densification)

This is the core transformative stage. Once dried, the furnace temperature begins to rise at a controlled rate, known as the ramp rate.

This heating phase first burns off any organic binders mixed into the ceramic material. As the temperature continues to rise to its peak, the process of sintering begins. During sintering, the individual ceramic particles fuse together, eliminating the pores between them and causing the material to shrink and densify.

This densification is what gives the final restoration its strength, durability, and desired translucency. The peak temperature and the length of time it is held there are critical for achieving complete sintering.

Stage 3: Cooling (Stabilizing the Structure)

After the high-temperature hold is complete, the furnace begins a controlled cooling process. This is not simply a matter of turning off the heat.

Cooling too rapidly can induce thermal shock, creating internal stresses that lead to cracking and failure. A controlled cooling rate allows the ceramic's crystalline structure to stabilize properly, locking in the strength and properties developed during sintering.

Why Precise Control is Non-Negotiable

The success of the entire firing process hinges on the furnace's ability to execute the programmed cycle with extreme accuracy. Modern dental furnaces are engineered for this exact purpose.

The Role of Temperature Accuracy

Even a deviation of a few degrees from the manufacturer's specified peak temperature can have a dramatic impact. It can alter the ceramic's shade, translucency, and physical strength. Furnaces use sophisticated sensors and heating elements to maintain precise control throughout the cycle.

The Importance of Time Parameters

It is not just the temperature that matters, but also the time. The ramp rate (how fast you heat up), the hold time at peak temperature, and the cooling rate are all critical variables that influence the degree of sintering and the final stability of the restoration.

Understanding the Key Variables

A firing cycle is not a one-size-fits-all program. It must be adapted based on several factors to avoid common failures like a poor fit, low strength, or incorrect aesthetics.

Material-Specific Cycles

Different types of dental ceramics, such as porcelain, lithium disilicate, or zirconia, have vastly different chemical compositions and melting points. Each material requires its own unique firing cycle, and following the manufacturer's instructions is the most critical rule for success.

The Impact of Restoration Thickness

The thickness and volume of the restoration directly influence the firing cycle. A thick molar crown requires a slower heating rate and potentially a longer hold time than a thin veneer. This ensures that heat penetrates the entire volume of the ceramic evenly, preventing an under-fired core.

Achieving Consistent, High-Quality Results

By understanding the function of each parameter, you can better control the outcome of your work and troubleshoot issues effectively.

- If your primary focus is aesthetics (e.g., veneers): Pay close attention to the peak temperature and hold time, as this directly controls the material's final translucency and shade.

- If your primary focus is strength (e.g., posterior crowns): Ensure the cycle allows for complete sintering to maximize densification and eliminate the porosity that weakens restorations.

- If you are troubleshooting failures (e.g., cracks or opacity): First, review your pre-drying and cooling stages, as improper moisture removal and thermal shock are the most common causes of cracks.

Mastering the principles of the firing cycle transforms it from a "black box" into a predictable and powerful tool for creating exceptional dental restorations.

Summary Table:

| Stage | Purpose | Key Parameters |

|---|---|---|

| Pre-Drying | Remove moisture to prevent bubbles/cracks | Low temperature, slow heating rate |

| Heating and Sintering | Densify ceramic for strength and translucency | Ramp rate, peak temperature, hold time |

| Cooling | Stabilize structure to avoid thermal shock | Controlled cooling rate |

Achieve flawless dental restorations with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise firing cycles tailored to your unique ceramic materials and restoration needs. Contact us today to enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision