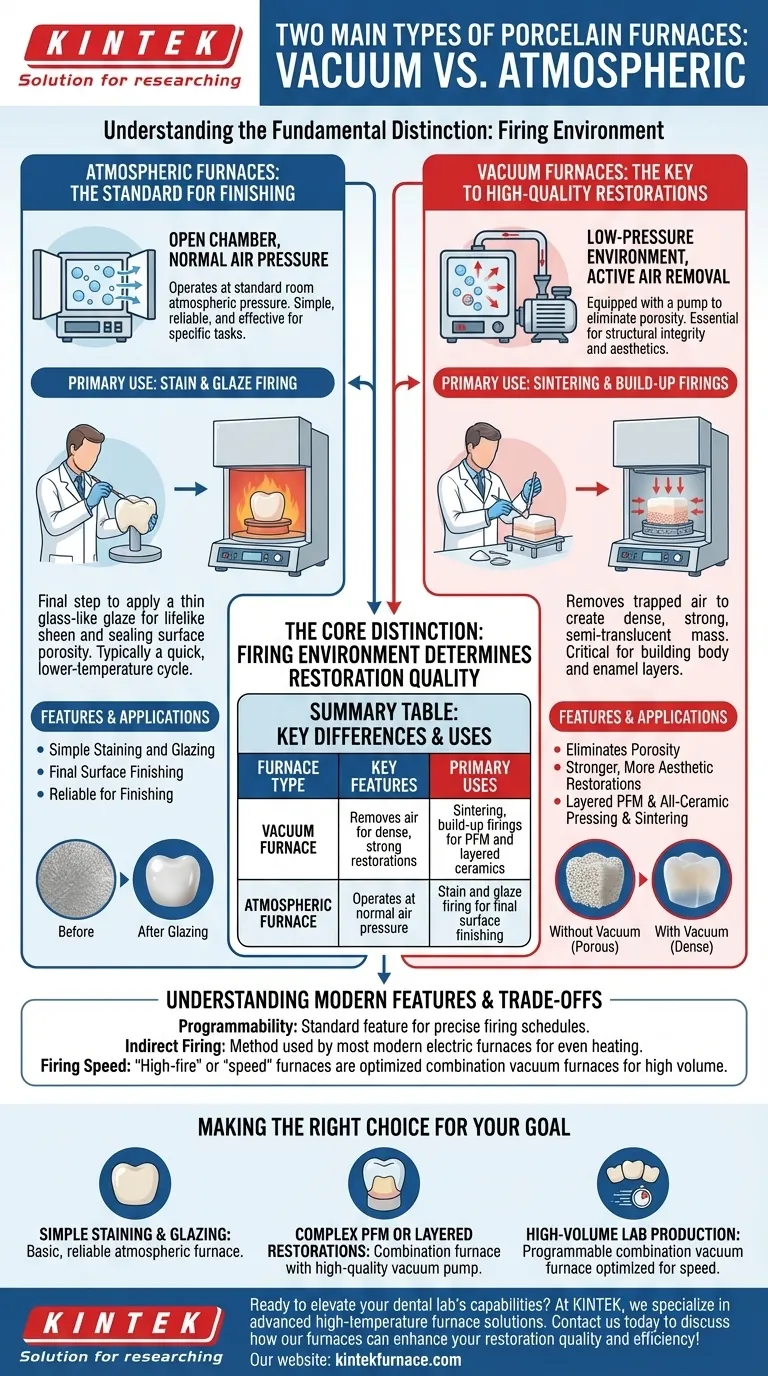

At their core, porcelain furnaces are distinguished by the environment in which they fire dental ceramics. The two fundamental types are vacuum furnaces, which remove air to create dense, strong restorations, and atmospheric furnaces, which operate at normal air pressure for simpler finishing processes. Most modern combination furnaces can perform both functions.

The critical distinction isn't the furnace model, but the process: firing under a vacuum is essential for the structural integrity and aesthetics of layered porcelain, while firing in a standard atmosphere is sufficient for final surface glazing.

Understanding the Fundamental Difference: Atmosphere vs. Vacuum

The quality of a final dental restoration is directly tied to the firing environment. The presence or absence of air during the heating cycle dramatically changes the final properties of the ceramic.

Atmospheric Furnaces: The Standard for Finishing

An atmospheric furnace operates with a firing chamber (known as a muffle) that is open to the surrounding air. The internal pressure is the same as the room's atmospheric pressure.

These furnaces use electric heating elements to reach the precise temperatures needed for processes that do not require the removal of air. They are simple, reliable, and effective for their specific tasks.

Their primary use is for stain and glaze firing. This is the final step where a thin layer of glass-like glaze is applied to the surface of a crown to give it a lifelike sheen and seal its surface porosity.

Vacuum Furnaces: The Key to High-Quality Restorations

A vacuum furnace is equipped with a pump that actively removes air from the muffle before and during the initial stages of the firing cycle. This creates a low-pressure environment.

The purpose of the vacuum is to eliminate porosity. When layers of porcelain powder are heated, trapped air can form microscopic bubbles, weakening the final structure and creating an opaque, chalky appearance.

By removing the air, the porcelain particles can fuse together into a dense, semi-translucent mass that is significantly stronger and more aesthetic. This process, called sintering, is critical for building the body and enamel layers of a crown or bridge.

The Role of the Furnace in Dental Restorations

A porcelain furnace is not used for just one task. It plays a role at multiple stages of creating a metal-ceramic or all-ceramic restoration.

Building the Restoration Layer by Layer

For porcelain-fused-to-metal (PFM) or layered zirconia crowns, a technician meticulously applies opaque, dentin, and enamel porcelains in powder/liquid form. Each layer is fired separately in the furnace.

These crucial "build-up" firings are performed under a vacuum to ensure each layer is dense, strong, and bonds correctly to the layer beneath it.

Pressing and Sintering

Some all-ceramic restorations are made from pressable ceramic ingots. In this process, the furnace heats the ceramic ingot until it becomes molten, then presses it into a mold—often under vacuum to ensure a void-free result.

For monolithic zirconia, the furnace performs a long sintering cycle that shrinks the milled "green state" material into its final, incredibly strong form.

Finalizing with Stain and Glaze

Regardless of how the crown was built, the final step is almost always a glaze fire. This is a quick, lower-temperature cycle performed in atmosphere to create a smooth, shiny, and non-porous surface.

Understanding the Trade-offs and Key Features

While atmosphere versus vacuum is the core distinction, modern furnaces are defined by other features that are often mistaken for fundamental "types."

The Importance of Programmability

Nearly all modern dental furnaces are programmable. This is not a type, but a standard feature. It allows the technician to create and save precise firing schedules—controlling temperature ramp rates, hold times, and vacuum levels—for the specific ceramic material being used.

The Myth of "Direct-Fired"

The terminology of "direct-fired" or "indirect-fired" is not a standard or useful classification for modern electric dental furnaces.

Virtually all contemporary furnaces use an indirect firing method. The electric heating elements (coils, quartz tubes, or silicon carbide rods) heat the chamber, and the chamber's radiant heat fires the restoration. This ensures even, controlled heating.

Firing Speed as a Feature

So-called "high-fire" or "speed" furnaces are not a distinct category but rather combination vacuum furnaces optimized for efficiency. They use advanced heating elements and insulation to reduce firing times, which is a major benefit for high-volume dental labs.

Making the Right Choice for Your Goal

The right furnace capability is dictated entirely by the dental restorations you intend to produce.

- If your primary focus is on simple staining and glazing of monolithic crowns: A basic, reliable atmospheric furnace is all that is required.

- If your primary focus is on building complex PFM or layered all-ceramic restorations: A combination furnace with a high-quality, reliable vacuum pump is absolutely essential.

- If your primary focus is on high-volume lab production: A programmable combination vacuum furnace with features optimized for speed and consistency is the most strategic investment.

Understanding the role of the vacuum is the key to mastering the art and science of modern dental ceramics.

Summary Table:

| Furnace Type | Key Features | Primary Uses |

|---|---|---|

| Vacuum Furnace | Removes air for dense, strong restorations | Sintering, build-up firings for PFM and layered ceramics |

| Atmospheric Furnace | Operates at normal air pressure | Stain and glaze firing for final surface finishing |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we can precisely meet your unique experimental and production needs. Contact us today to discuss how our furnaces can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab