Dental Furnace

Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

Item Number : KT-DV10

Price varies based on specs and customizations

- Max temperature

- 1200℃ max(2283°F)

- Heating speed

- 200℃/min max. (392°F /minute)

- Vacuum level

- 1-101%

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

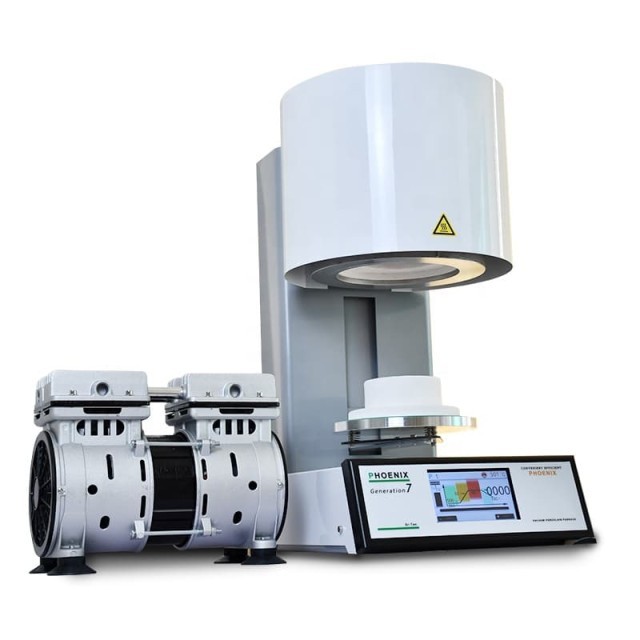

KinTek Vacuum Porcelain Furnace

Product Showcase

The KinTek Vacuum Porcelain Furnace is engineered for precision and efficiency in dental laboratories. It excels in fabricating high-quality pressed-ceramic restorations by utilizing a combined firing and pressing mechanism. This advanced system employs controlled heat and pressure to liquefy ceramic blocks and precisely force them into refractory investment molds, ensuring exceptional results for a wide range of dental applications.

Key Features & Benefits

- Advanced Firing Control: Features a hyperbolic ceramic furnace function, with programmable single curve or hyperbolic modes. The hyperbolic mode is optimized for a complete crystallization process, ideal for glass-ceramics.

- User-Friendly Operation: Equipped with a true color touch screen for easy navigation and voice prompt functionality for guided operation.

- Precision Temperature Management: Ensures high-quality, consistent results with automatic temperature adjustment (actual temperature error within +/- 1°C) and automatic temperature calibration before each baking cycle.

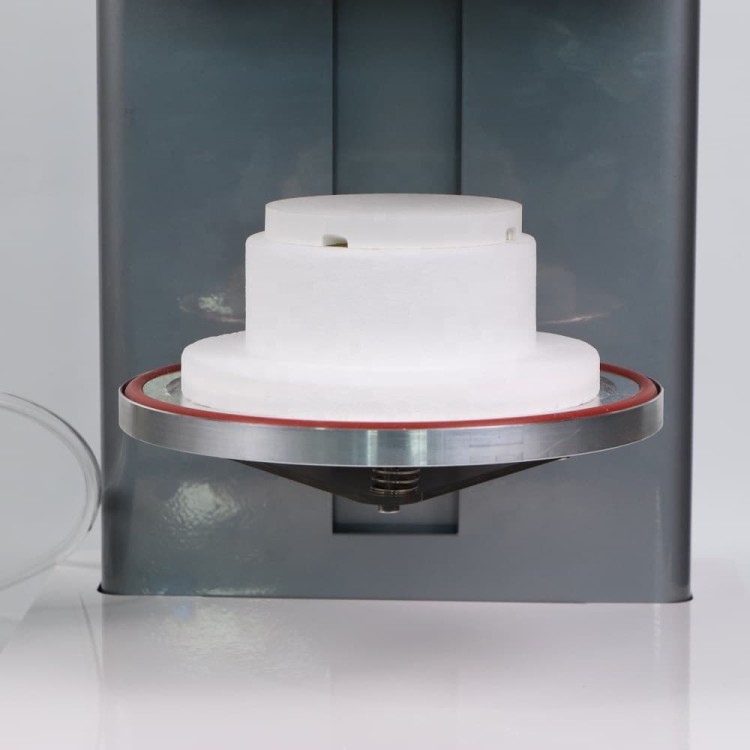

- Smooth & Quiet Performance: Utilizes a precision stepper motor drive for smooth, jitter-free tray operation and a low-noise tray design.

- Efficient Design: Features a durable quartz spiral furnace for optimal heating.

- Versatile Programming: Offers 90 customizable programs alongside built-in programs to suit diverse needs.

- Clear Status Indication: Provides real-time updates on the operational status.

Primary Applications

The KinTek Phoenix Generation 7 Vacuum Porcelain Furnace is expertly designed for:

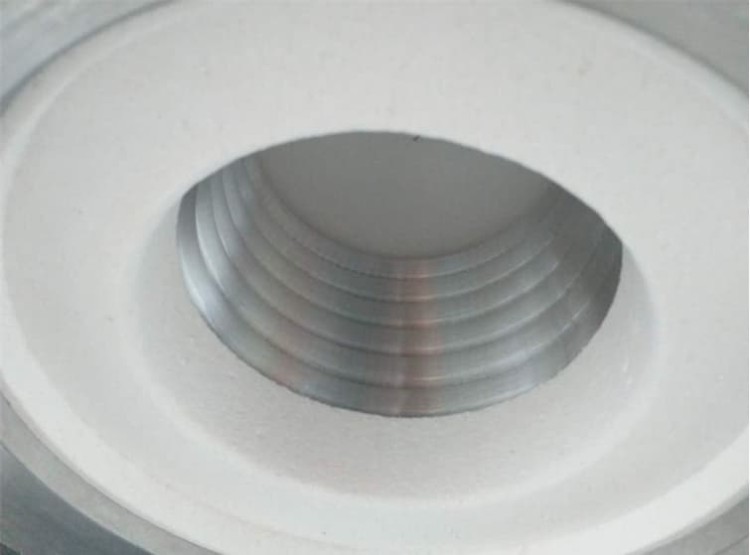

- Fabricating Pressed-Ceramic Restorations: It employs a combined firing/pressing mechanism, utilizing specialized firing chambers and pressure plungers. This process, which resembles casting, uses controlled pressure and heat to liquefy ceramic blocks and precisely force them into lost, refractory investment molds.

- Wide Material Compatibility: Suitable for use with all kinds of porcelain powders available on the market, including those from leading manufacturers like IVOCLAR, VITA, NORITAKE, and others.

Technical Specifications

| Heating speed | 200℃/min max. (392°F /minute) |

| Max temperature | 1200℃ max(2283°F) |

| Max temperature holding time | 2 hours |

| Vacuum level | 1-101% |

| Electric power supply | 100-120V 50/60HZ 230V 50/60HZ |

| Rated current | 14.5ampere@110V 7.0ampere@230V |

| Rated output power | max 1500w |

| Dimension | H27cm x W36cm x D53cm |

| Firing chamber diameter | 9cm(3.5") |

| Net weight | 20Kg |

| Weight with package | 23.5Kg |

Ambient Operating Conditions

- Indoor use

- Ambient temperature: 2°C to 40°C

- Relative humidity 80% at 31°C

- Maximum altitude: 1500 m (Special Model: 3500m)

- Rated voltage fluctuations must not exceed plus/minus 10% of the rated voltage

What's Included

- 1 Furnace

- 1 Firing pan

- 1 Connection cable for the mains power supply

- 1 Set of Instructions

- 1 Burning rack

Why Choose KINTEK for Your Laboratory?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Ready to enhance your laboratory's capabilities with the Phoenix Generation 7 or explore a custom furnace solution?

Our experts are here to help. Contact us today to discuss your specific needs and learn how KINTEK can support your work.

FAQ

What Is The Principle Of A Porcelain Furnace?

What Is A Dental Furnace Used For?

What Are The Main Applications Of A Vacuum Furnace?

What Is An Atmosphere Furnace Used For?

What Are The Advantages Of Using A Porcelain Furnace?

What Are The Key Features Of A Dental Furnace?

What Are The Key Features Of A Vacuum Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Applications Of A Porcelain Furnace?

How Does A Dental Furnace Work?

How Does A Vacuum Furnace Work?

How Does An Atmosphere Furnace Work?

What Safety Features Should A Porcelain Furnace Have?

What Are The Advantages Of Using A Dental Furnace?

What Are The Advantages Of Using A Vacuum Furnace?

What Are The Advantages Of Using An Atmosphere Furnace?

What Advanced Features Do Some Porcelain Furnaces Offer?

What Safety Features Should A Dental Furnace Have?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Types Of Dental Furnaces Are Available?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

Can Vacuum Furnaces Be Customized For Specific Applications?

4.9

out of

5

This furnace is a game-changer! The precision and consistency are unmatched. Worth every penny!

4.8

out of

5

Fast delivery and easy setup. The quality of sintering is exceptional. Highly recommend!

4.7

out of

5

Incredible value for money. The furnace works flawlessly and has improved our lab's efficiency.

4.9

out of

5

Top-notch technology! The vacuum feature ensures perfect results every time. A must-have!

4.8

out of

5

Durable and reliable. Our lab has seen a significant reduction in defects since using this furnace.

4.7

out of

5

The speed and accuracy of this furnace are impressive. It’s transformed our workflow!

4.9

out of

5

Outstanding performance! The furnace delivers consistent results with minimal maintenance.

4.8

out of

5

A fantastic investment. The advanced features make it stand out from competitors.

4.7

out of

5

Superb craftsmanship. The furnace is built to last and performs exceptionally well.

4.9

out of

5

Love the precision! This furnace has elevated the quality of our dental restorations.

4.8

out of

5

Quick delivery and excellent customer service. The furnace exceeds expectations.

4.7

out of

5

Highly efficient and user-friendly. Our lab’s productivity has soared with this furnace.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

600T Vacuum Induction Hot Press Furnace for precise sintering. Advanced 600T pressure, 2200°C heating, vacuum/atmosphere control. Ideal for research & production.

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Compact vacuum tungsten wire sintering furnace for labs. Precise, mobile design with superior vacuum integrity. Ideal for advanced material research. Contact us!

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

Precision Vacuum Press Furnace for labs: ±1°C accuracy, 1200°C max, customizable solutions. Boost research efficiency today!

Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

Dental Porcelain Speedy Sintering Furnace: Fast 9-minute zirconia sintering, 1530°C precision, SiC heaters for dental labs. Boost productivity today!

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

Vacuum Induction Melting Furnace and Arc Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems for precision applications. Customizable, durable, and leak-tight. Get expert solutions now!