At its core, a dental zirconia sintering furnace is a highly specialized piece of equipment designed for a narrow range of materials. It is purpose-built to process pre-sintered zirconia blocks, fire various glass ceramics, and perform the final glazing and staining of dental restorations.

While a dental sintering furnace is technically a type of high-temperature oven, it is not a general-purpose laboratory furnace. Its value and proper function depend on using it exclusively for the clean, specific materials required in dental prosthetics to avoid contamination and ensure clinical success.

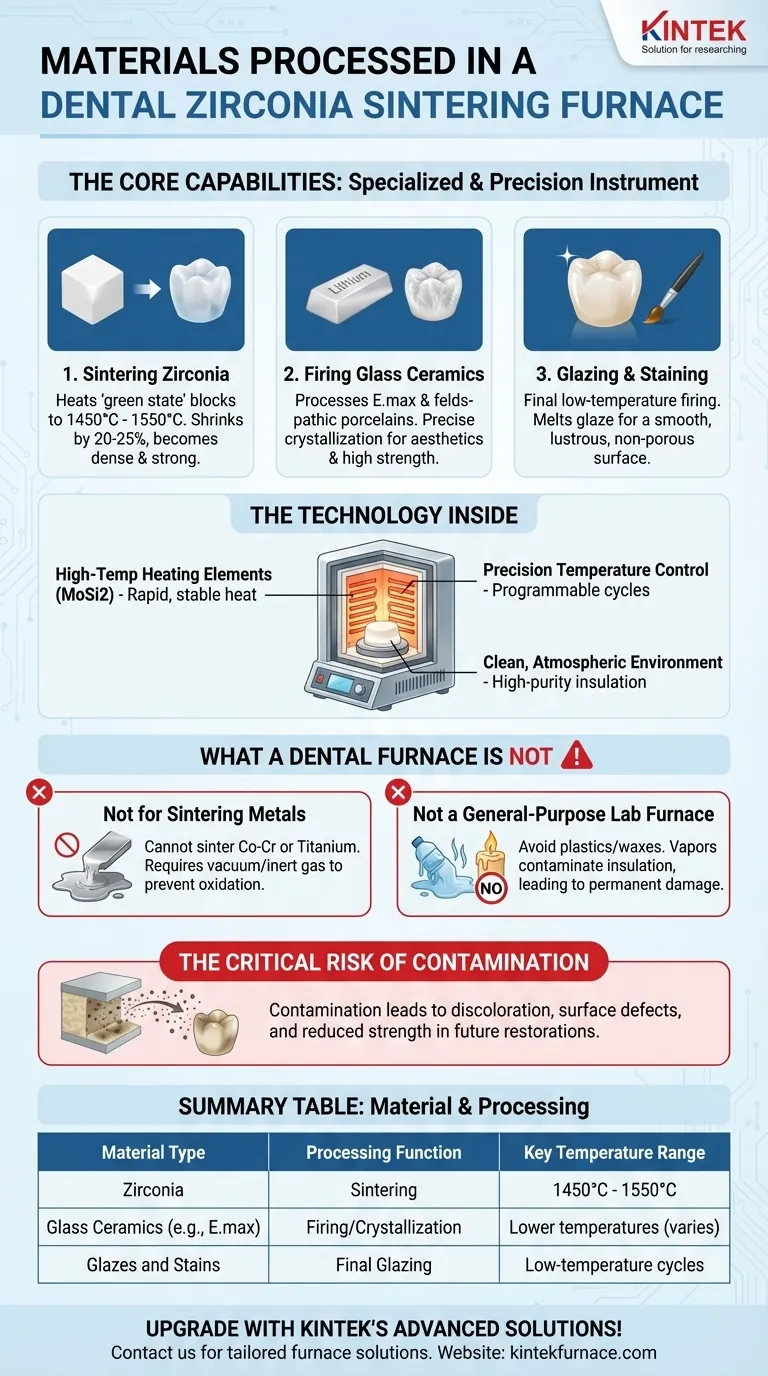

The Core Capabilities: Sintering Dental Restorations

A modern dental furnace is a precision instrument central to the digital dentistry workflow. Its functions are tailored to transform milled materials into final, patient-ready restorations.

Sintering Zirconia

This is the furnace's primary function. Zirconia restorations are milled from a soft, chalk-like block. The sintering process heats these "green state" restorations to very high temperatures, typically between 1450°C and 1550°C.

This controlled heating cycle shrinks the restoration by 20-25% and transforms it into a dense, incredibly strong ceramic with its final desired translucency and shade.

Firing Glass Ceramics

The furnace is also essential for processing glass ceramics like lithium disilicate (e.g., E.max) or feldspathic porcelains. These materials require a different, often lower, temperature profile.

During firing, the furnace executes a precise crystallization process that gives these materials their excellent aesthetics and high strength.

Glazing and Staining

This is the final step for most ceramic restorations. The furnace is used for a low-temperature firing cycle that melts a thin layer of liquid glass (glaze) onto the restoration's surface.

This creates a smooth, lustrous, and non-porous surface that mimics natural enamel and helps prevent plaque accumulation. Technicians often add surface stains during this cycle to perfect the shade and characterization.

What Governs These Capabilities? The Technology Inside

The furnace's capabilities are not arbitrary; they are a direct result of its specialized components designed for a contamination-free, high-heat environment.

High-Temperature Heating Elements

Most dental sintering furnaces use Molybdenum Disilicide (MoSi2) heating elements. These are critical because they can rapidly reach and sustain the extreme temperatures required for zirconia without breaking down or releasing contaminants.

Precision Temperature Control

Sophisticated programmable controllers and thermocouples allow for exact temperature management. Different ceramics require unique heating rates, hold times, and cooling rates.

This precision is what allows the same furnace to handle both high-temperature zirconia and lower-temperature glass ceramics without causing thermal shock, cracks, or incomplete sintering.

Clean, Atmospheric Environment

Unlike furnaces used for industrial metals, a dental furnace operates at normal atmospheric pressure. Its chamber is engineered with high-purity insulation to create a clean environment free from particles that could discolor a restoration.

Understanding the Trade-offs: What a Dental Furnace Is NOT

Understanding the furnace's limitations is as important as knowing its capabilities. Using it for unapproved materials can permanently damage the unit or compromise the quality of future restorations.

Not for Sintering Metals

A dental furnace cannot sinter metal powders like those used in SLM (Selective Laser Melting) for cobalt-chrome or titanium frameworks. Sintering metals requires a vacuum or an inert gas atmosphere (like argon) to prevent rapid, destructive oxidation. A standard dental furnace does not have this capability.

Not a General-Purpose Lab Furnace

While it is a type of muffle furnace, it should never be treated as a general-purpose oven for heating plastics, waxes, or other materials. These materials can release vapors that impregnate the furnace's insulation.

The Critical Risk of Contamination

Once the insulation is contaminated, it can release those impurities during subsequent high-temperature cycles. This can lead to discoloration, surface defects, and reduced strength in the expensive zirconia and glass-ceramic restorations you produce later, rendering the furnace unreliable for its primary task.

Making the Right Choice for Your Workflow

To maximize the value and lifespan of your furnace, you must align its use with your primary production goals.

- If your primary focus is crown and bridge production: Dedicate the furnace exclusively to zirconia, glass ceramics, and their associated glazes to ensure the purity and aesthetic quality of every restoration.

- If you work with both zirconia and low-fusing pressable ceramics: Consider using separate furnaces. This prevents cross-contamination between different ceramic systems and optimizes the workflow for each material's unique requirements.

- If you need to process metal frameworks: You must invest in a different type of system, such as a vacuum-atmosphere sintering furnace or a casting machine designed specifically for dental alloys.

Ultimately, treating your dental furnace as a specialized instrument, not a general-purpose oven, is the key to producing consistent, high-quality clinical outcomes.

Summary Table:

| Material Type | Processing Function | Key Temperature Range |

|---|---|---|

| Zirconia | Sintering | 1450°C - 1550°C |

| Glass Ceramics (e.g., E.max) | Firing/Crystallization | Lower temperatures (varies) |

| Glazes and Stains | Final Glazing | Low-temperature cycles |

Upgrade your dental lab's precision and efficiency with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for sintering zirconia, firing ceramics, and more—delivering contamination-free, high-quality results. Contact us today to discuss how our tailored furnace solutions can enhance your workflow and clinical outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations