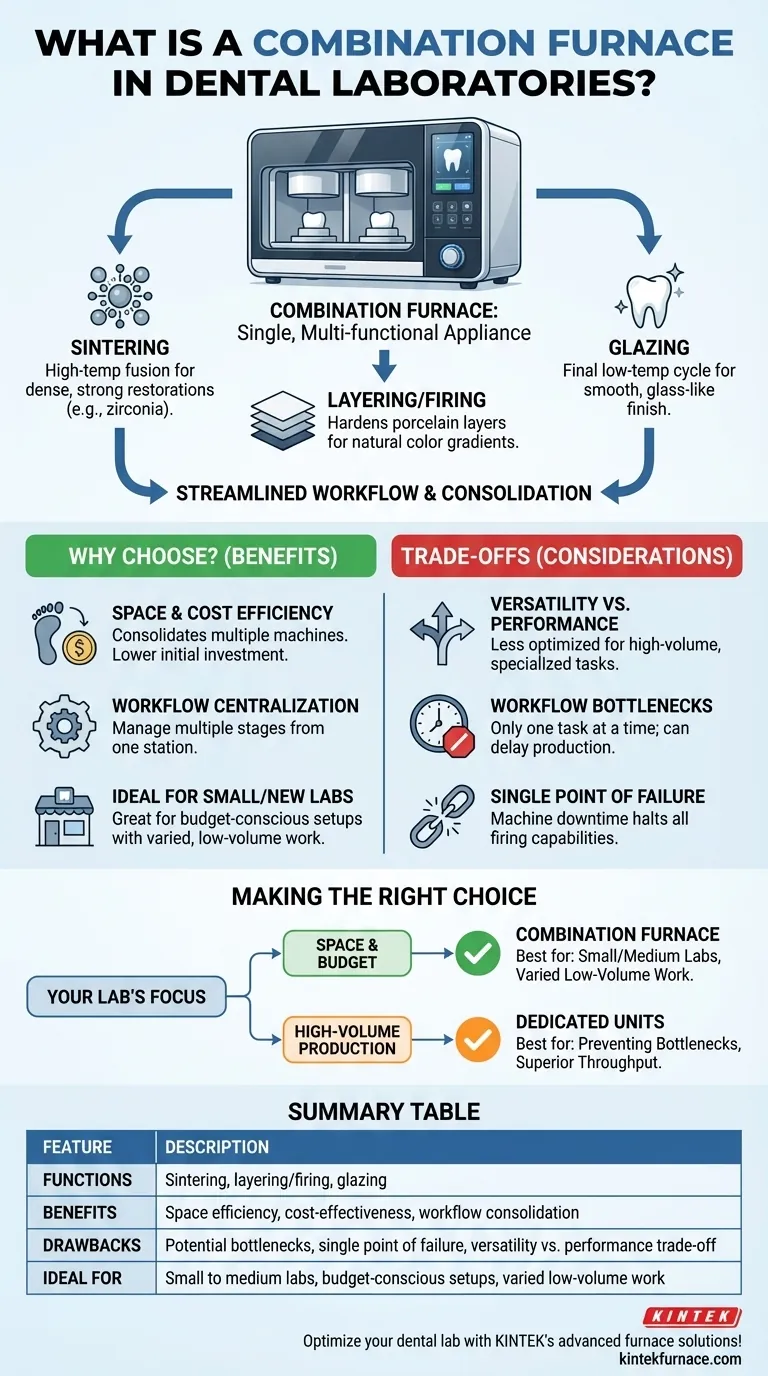

In a dental laboratory, a combination furnace is a single, multi-functional appliance designed to perform several distinct heating and firing processes required to create dental restorations. This allows technicians to handle tasks such as sintering, glazing, and porcelain layering within one piece of equipment, consolidating what would otherwise require multiple specialized machines.

A combination furnace streamlines the dental lab workflow by merging multiple heating tasks into one device. While this offers significant space and cost advantages, it's crucial to understand the trade-off between this versatility and the focused performance of single-purpose furnaces.

The Role of Controlled Heat in Dental Restorations

A furnace is the heart of a modern dental lab, transforming raw ceramic materials into durable and aesthetic prosthetics like crowns, bridges, and veneers.

The Need for a Precise Thermal Environment

Dental ceramics, such as porcelain, achieve their final strength, color, and translucency only after being subjected to a precise, computer-controlled heating cycle. This process, often conducted in a sealed "muffle" chamber, ensures uniform heat distribution and prevents contamination.

The furnace's ability to accurately follow a programmed temperature curve is critical for predictable, high-quality results that match a patient's natural dentition.

Key Processes Handled by a Combination Furnace

A combination furnace gets its name from its ability to handle several distinct thermal processes.

- Sintering: This is a high-temperature process that fuses ceramic particles (like zirconia) into a dense, solid, and incredibly strong final state.

- Layering/Firing: Technicians build up a restoration with multiple layers of porcelain powder to achieve natural color gradients. The furnace fires each layer to harden it.

- Glazing: This is a final, lower-temperature firing cycle that melts a thin surface layer, creating a smooth, non-porous, and aesthetically pleasing glass-like finish on the restoration.

Why a Lab Might Choose a Combination Furnace

The decision to use a combination furnace is primarily driven by operational and economic factors.

Space and Workflow Efficiency

For many dental labs, particularly smaller ones, physical space is a premium. A combination furnace consolidates the footprint of two or three separate machines into one.

This also centralizes a critical part of the workflow, as a technician can manage multiple stages of fabrication from a single station and interface.

Cost-Effectiveness

The initial capital investment for one multi-function furnace is typically lower than purchasing separate, dedicated sintering and porcelain furnaces. This makes it an attractive option for new labs or those looking to upgrade on a budget.

Understanding the Trade-offs

While versatile, a combination furnace is not always the superior choice. The "jack-of-all-trades" nature comes with important considerations.

Versatility vs. Specialized Performance

A dedicated, single-purpose machine is often optimized for its specific task. For example, a dedicated sintering furnace may handle high-volume zirconia production more efficiently than a combination unit that must also cater to lower-temperature porcelain firing.

Potential for Workflow Bottlenecks

The most significant operational drawback is that the furnace can only perform one task at a time. If the unit is occupied with a long, multi-hour sintering cycle, no other restorations can be glazed or fired.

In a high-volume lab, this creates a production bottleneck that separate, dedicated furnaces would easily solve.

A Single Point of Failure

Relying on one machine for multiple critical functions introduces risk. If the combination furnace requires maintenance or repair, all of the lab's firing and sintering capabilities are halted, stopping production entirely.

Making the Right Choice for Your Lab

The decision between a combination furnace and dedicated units should be based on your lab's specific operational needs.

- If your primary focus is maximizing space and minimizing initial investment: A combination furnace is an excellent choice, especially for smaller labs or those just starting.

- If your primary focus is high-volume, specialized production: Dedicated single-purpose furnaces (e.g., a separate sintering furnace and porcelain furnace) will prevent workflow bottlenecks and offer superior throughput.

- If your primary focus is workflow flexibility: A combination unit may be sufficient for a lab with varied but low-volume work, whereas a high-volume lab will gain more flexibility from having multiple specialized machines running in parallel.

Ultimately, selecting the right furnace depends on a clear analysis of your lab's specific production volume, workflow, and long-term growth strategy.

Summary Table:

| Feature | Description |

|---|---|

| Functions | Sintering, layering/firing, glazing |

| Benefits | Space efficiency, cost-effectiveness, workflow consolidation |

| Drawbacks | Potential bottlenecks, single point of failure, versatility vs. performance trade-off |

| Ideal For | Small to medium labs, budget-conscious setups, varied low-volume work |

Optimize your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and quality. Contact us today to discuss how we can support your lab's growth and performance!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations