In dentistry, porcelain is used to fabricate a wide range of custom dental restorations that restore the function and appearance of teeth. These include crowns, bridges, veneers, inlays, and onlays, which are designed to repair damage from decay or trauma, correct cosmetic imperfections, and replace missing teeth with a durable, biocompatible, and natural-looking material.

The core value of dental porcelain lies in its unique ability to mimic the strength, biocompatibility, and aesthetic qualities of natural tooth enamel. Its use is not just about repair; it is about creating restorations that are virtually indistinguishable from real teeth.

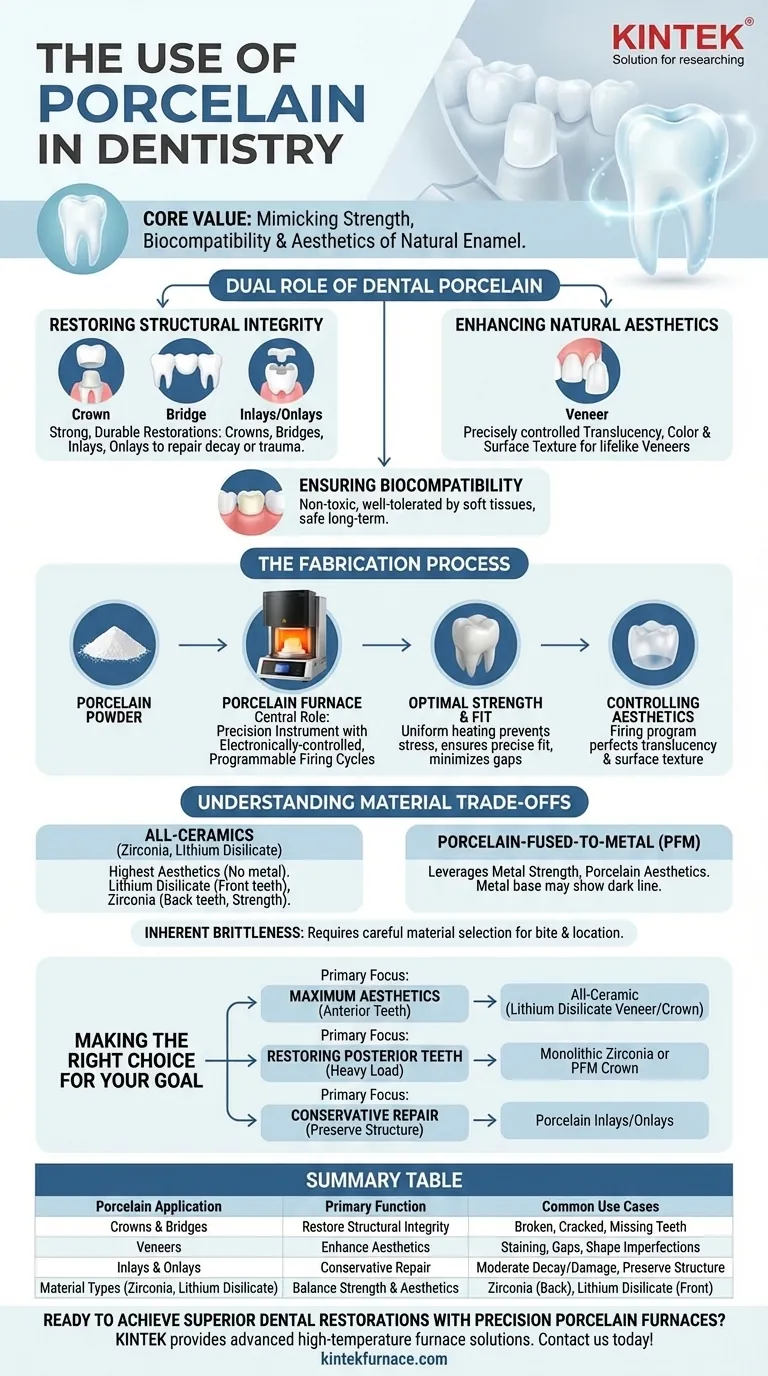

The Dual Role of Dental Porcelain

Dental porcelain, a specialized ceramic, serves two critical functions simultaneously: restoring the mechanical integrity of the bite and recreating the lifelike appearance of a healthy smile.

Restoring Structural Integrity

Porcelain is used to create strong, durable restorations for teeth that are broken, cracked, or weakened by decay. Restorations like crowns cover the entire tooth to protect it, while bridges replace one or more missing teeth by anchoring to adjacent ones.

More conservative options like inlays and onlays are used to repair smaller areas of damage, fitting into a tooth much like a puzzle piece to restore its original shape and strength.

Enhancing Natural Aesthetics

The material's greatest strength is its aesthetic quality. Its translucency, color (hue and chroma), and surface texture can be precisely controlled to match surrounding teeth perfectly.

This makes it the ideal material for veneers, which are thin shells bonded to the front of teeth to correct issues like staining, gaps, or improper shape. The goal is to enhance appearance while looking completely natural.

Ensuring Biocompatibility

Porcelain is highly biocompatible, meaning it is non-toxic and well-tolerated by the soft tissues in the mouth. This ensures that restorations do not cause irritation or allergic reactions, making them a safe and reliable long-term solution.

The Fabrication Process: From Powder to Prosthesis

The final properties of a porcelain restoration are not inherent to the raw material alone. They are developed through a highly controlled fabrication process centered around a key piece of equipment: the porcelain furnace.

The Central Role of the Porcelain Furnace

A porcelain furnace is not merely an oven; it is a precision instrument. Modern furnaces use electronically-controlled, programmable firing cycles to heat the raw ceramic material to an optimal level of maturity.

This precise heating is what transforms the porcelain powder into a dense, solid, and durable final restoration.

Achieving Optimal Strength and Fit

During the firing cycle, the furnace ensures uniform heating, which is critical for preventing internal stresses and ensuring a precise fit. This accuracy minimizes the gap between the restoration and the tooth, reducing the risk of future decay.

The result is a highly durable restoration that can withstand the forces of chewing for many years, making it a cost-effective solution.

Controlling Aesthetic Properties

The firing program directly controls the final aesthetic outcome. By managing the temperature and duration of the cycle, a dental technician can perfect the restoration's translucency and surface texture. This step is what brings the prosthesis to life, making it indistinguishable from natural enamel.

Understanding the Material Trade-offs

While porcelain is a superior material, different types of dental ceramics are chosen based on the specific clinical need, each presenting a unique balance of strength and aesthetics.

All-Ceramics (e.g., Zirconia, Lithium Disilicate)

These materials offer the highest level of aesthetics because they contain no metal. Lithium disilicate is renowned for its excellent translucency, making it a top choice for veneers and crowns on front teeth. Zirconia offers exceptional strength, often preferred for crowns and bridges on back teeth that endure heavy chewing forces.

Porcelain-Fused-to-Metal (PFM)

A classic and reliable option, a PFM restoration consists of a metal alloy framework covered by a layer of porcelain. This design leverages the strength of the metal substructure while providing the aesthetic appearance of porcelain. The primary trade-off is that the metal base can sometimes create a dark line at the gumline.

Inherent Brittleness

Like all ceramics, dental porcelain can be brittle under specific types of sharp, focused impact. The fabrication process in the porcelain furnace is designed to maximize its strength, but the choice of material must still account for the patient's bite and the location of the tooth being restored.

Making the Right Choice for Your Goal

The selection of a specific porcelain restoration depends entirely on the clinical objective, balancing the need for strength, aesthetics, and tooth preservation.

- If your primary focus is maximum aesthetics for anterior (front) teeth: An all-ceramic restoration like a lithium disilicate veneer or crown is the premier choice for its lifelike translucency.

- If your primary focus is restoring posterior (back) teeth under heavy load: A monolithic zirconia crown or a porcelain-fused-to-metal (PFM) crown provides the necessary strength and durability.

- If your primary focus is a conservative repair that preserves tooth structure: Porcelain inlays and onlays are the ideal solution for repairing moderate decay or damage without covering the entire tooth.

Ultimately, dental porcelain is the cornerstone of modern restorative dentistry, enabling clinicians to rebuild smiles that are both functional and beautiful.

Summary Table:

| Porcelain Application | Primary Function | Common Use Cases |

|---|---|---|

| Crowns & Bridges | Restore structural integrity | Repair broken, cracked, or missing teeth |

| Veneers | Enhance aesthetics | Correct staining, gaps, or shape imperfections |

| Inlays & Onlays | Conservative repair | Fill moderate decay/damage while preserving tooth structure |

| Material Types (Zirconia, Lithium Disilicate) | Balance strength & aesthetics | Zirconia for back teeth, Lithium Disilicate for front teeth |

Ready to achieve superior dental restorations with precision porcelain furnaces?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide dental labs with advanced high-temperature furnace solutions. Our Muffle, Tube, and Vacuum & Atmosphere Furnaces—complemented by strong deep customization capabilities—ensure optimal firing cycles for durable, aesthetically perfect porcelain crowns, bridges, and veneers.

Contact us today to discuss how our furnaces can elevate your restorative outcomes! Get in touch →

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What is the main purpose of a sintering furnace in dentistry? Transform Zirconia into Strong Dental Restorations

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- What should routine inspections of dental furnaces include? Ensure Consistent, High-Quality Dental Restorations