In simple terms, the main purpose of a dental sintering furnace is to transform a soft, chalk-like ceramic dental restoration into its final, high-strength state through a process of intense, controlled heating. This crucial step happens after the restoration—such as a crown or bridge—has been milled from a block of zirconia.

A milled zirconia crown is too weak to be placed in a patient's mouth. The sintering furnace is the essential tool that uses precisely controlled heat, often exceeding 1,500°C, to fuse the ceramic particles, dramatically increasing the material's density and strength.

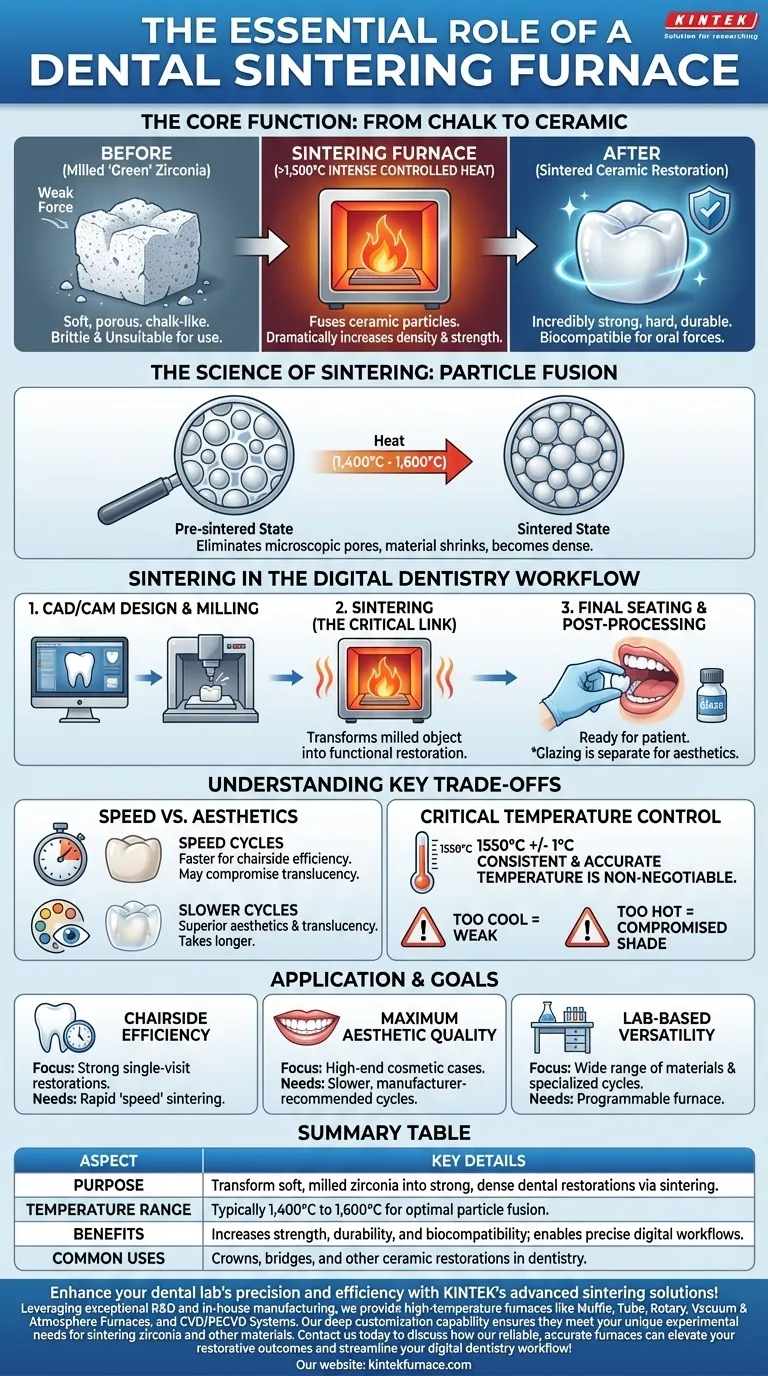

The Core Function: From Chalk to Ceramic

The magic of modern ceramic restorations lies in a fundamental material transformation. The sintering furnace is the catalyst for this change.

Transforming Milled Material

Dental zirconia is typically milled in a soft, "green" or pre-sintered state. This makes the milling process faster, more accurate, and reduces wear on the milling burs.

However, in this state, the material is porous and brittle, completely unsuitable for the functional demands of the mouth.

The Science of Sintering

Inside the furnace, the restoration is heated according to a precise temperature and time protocol. At these high temperatures (typically 1,400°C to 1,600°C), the individual ceramic particles fuse together.

This process, known as sintering, eliminates the microscopic pores between particles. The material shrinks significantly and becomes much denser.

The Result: Strength and Durability

The final sintered restoration is incredibly strong, hard, and biocompatible. It can now withstand the powerful chewing forces generated in the oral cavity.

This process gives zirconia its reputation for durability, making it one of the most reliable materials in modern restorative dentistry.

Sintering in the Digital Dentistry Workflow

The sintering furnace is not a standalone device; it's a critical link in the chain of digital dentistry (CAD/CAM).

The Bridge Between Milling and Seating

After a restoration is digitally designed (CAD) and milled (CAM), it is not yet complete. Sintering is the essential post-processing step that prepares the restoration for the patient.

Without sintering, the benefits of fast and precise milling would be useless, as the restoration would lack the required strength.

Beyond Zirconia: Other Materials

While zirconia is the most common material requiring this process, sintering furnaces are also used to process other materials, such as certain non-precious metal alloys used in dentistry.

Glazing and Staining

After sintering, restorations are often stained for custom color matching and glazed to create a smooth, natural-looking surface. While some furnaces can perform these lower-temperature firings, glazing is a separate aesthetic process from sintering, which is for structural integrity.

Understanding the Key Trade-offs

The sintering process is not one-size-fits-all. Different cycle parameters can impact the final result, and precision is paramount.

Cycle Time vs. Final Aesthetics

Many modern furnaces offer "speed" cycles that can sinter a crown in a fraction of the time of traditional cycles. This is excellent for chairside, single-visit dentistry.

However, slower, longer cycles often result in superior translucency and aesthetics. The choice involves a trade-off between clinical efficiency and the highest possible cosmetic outcome, especially for visible front teeth.

Temperature Accuracy is Non-Negotiable

The final properties of zirconia are directly tied to the peak temperature and heating rate. A furnace that runs too cool will produce a weak restoration, while one that runs too hot can compromise the material's shade and translucency.

Consistent, accurate temperature control is the single most important feature of a reliable sintering furnace.

The Importance of a Controlled Atmosphere

High-end furnaces often perform sintering under a vacuum or a controlled atmosphere. This prevents contaminants from the air from reacting with the ceramic at high temperatures, ensuring a clean and consistent final product.

Applying This to Your Clinical or Lab Goal

The ideal sintering protocol depends entirely on the desired outcome for a specific case.

- If your primary focus is chairside efficiency: A furnace with validated, rapid "speed" sintering cycles is critical for delivering strong single-visit restorations.

- If your primary focus is maximum aesthetic quality: Using slower, manufacturer-recommended sintering cycles will yield the best translucency and shade matching for high-end cosmetic cases.

- If your primary focus is lab-based versatility: You need a programmable furnace that can reliably handle a wide range of materials and custom firing cycles for specialized restorations.

Ultimately, the sintering furnace is the unsung hero that turns a digital file into a durable, real-world dental solution.

Summary Table:

| Aspect | Key Details |

|---|---|

| Purpose | Transform soft, milled zirconia into strong, dense dental restorations via sintering. |

| Temperature Range | Typically 1,400°C to 1,600°C for optimal particle fusion. |

| Benefits | Increases strength, durability, and biocompatibility; enables precise digital workflows. |

| Common Uses | Crowns, bridges, and other ceramic restorations in dentistry. |

Enhance your dental lab's precision and efficiency with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures they meet your unique experimental needs for sintering zirconia and other materials. Contact us today to discuss how our reliable, accurate furnaces can elevate your restorative outcomes and streamline your digital dentistry workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision