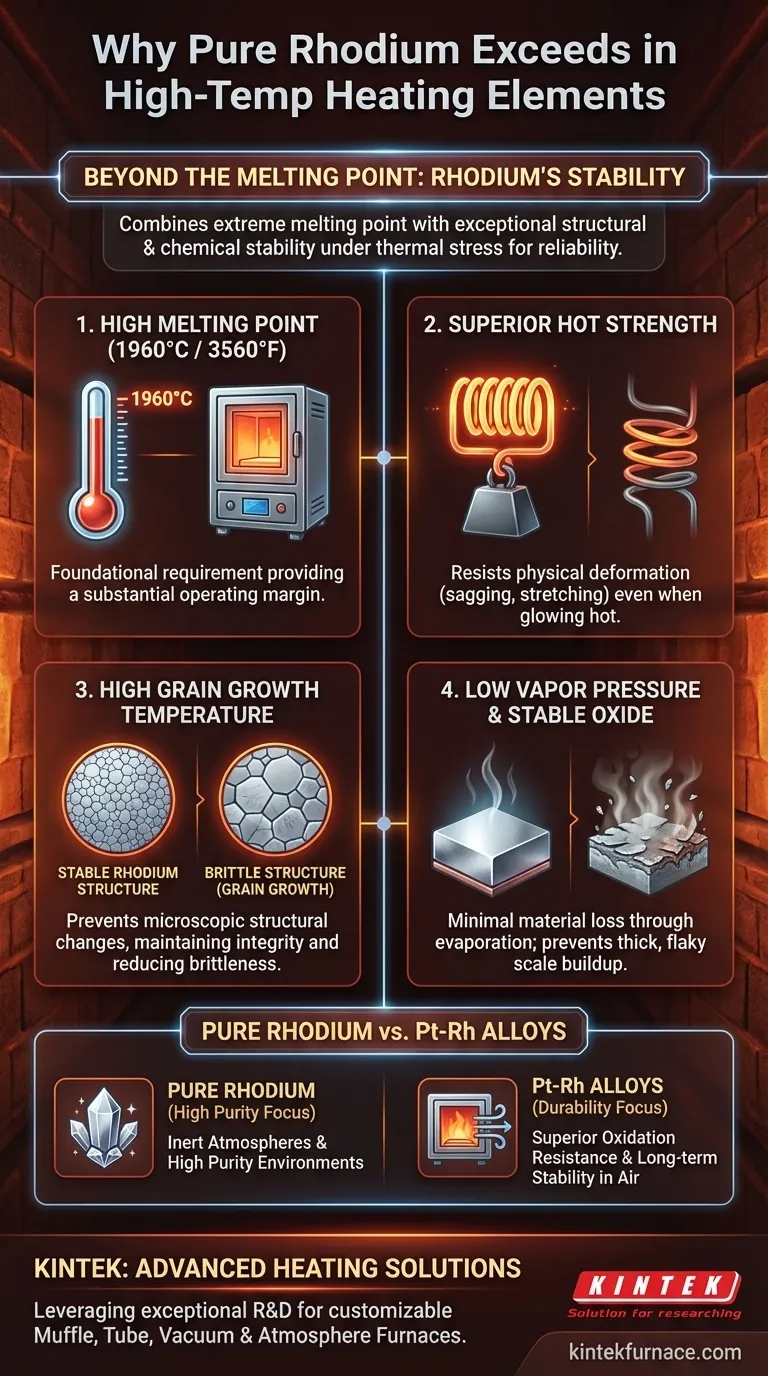

In short, pure rhodium is an excellent material for high-temperature heating elements because it combines an extremely high melting point with exceptional structural and chemical stability under thermal stress. Its resistance to degradation at a microscopic level ensures reliability and a long operational lifespan in demanding environments.

The suitability of a heating element is defined by more than just its melting point. True performance comes from a material's ability to resist physical deformation (hot strength), microscopic structural changes (grain growth), and chemical breakdown (oxidation and evaporation) when held at extreme temperatures for long periods.

The Core Properties of Rhodium for High-Temperature Use

To understand why rhodium is a premier choice, we must look beyond its ability to simply withstand heat. Its value lies in its stability across multiple physical and chemical vectors.

High Melting Point: The Foundational Requirement

The most obvious characteristic is its high melting point of 1960°C (3560°F). This provides a substantial operating margin for the vast majority of high-temperature industrial processes, ensuring the element does not fail by melting.

Hot Strength: Resisting Deformation Under Heat

Materials weaken as they get hotter. Rhodium possesses superior hot strength, meaning it maintains its structural integrity and resists sagging, stretching, or breaking even when glowing hot. This physical resilience is critical for elements shaped into coils or complex forms.

High Grain Growth Temperature: The Key to Durability

At a microscopic level, metals are composed of crystalline structures called grains. At high temperatures, these grains can merge and grow larger, a phenomenon called grain growth, which makes the material brittle and prone to failure.

Rhodium has a very high grain growth temperature, meaning its internal structure remains stable and strong. This resistance to microstructural degradation is a primary reason for its long-term durability in constant-use furnaces.

Vapor Pressure & Oxide Evaporation: Ensuring Longevity

All materials evaporate, and the rate increases with temperature. Rhodium has a very low vapor pressure, meaning it evaporates extremely slowly even at high temperatures, leading to minimal material loss over time.

Furthermore, while it does form an oxide in the presence of air, this rhodium oxide layer also evaporates at a favorable rate. This prevents the buildup of a thick, flaky scale that could compromise the heating element's integrity.

Understanding the Trade-offs: Pure Rhodium vs. Alloys

While pure rhodium is highly effective, it is not the only option. Understanding its place relative to its alloys is crucial for proper material selection.

The Case for Pure Rhodium

Pure rhodium is often specified in applications where chemical purity is paramount. This includes certain types of crystal growth, glass manufacturing, or laboratory furnaces where even trace contamination from an alloying element (like platinum) is unacceptable.

The Advantage of Platinum-Rhodium Alloys

For many industrial applications, platinum-rhodium (Pt-Rh) alloys are the preferred choice. Alloying rhodium with platinum can further improve key properties, often resulting in even better oxidation resistance and lower vapor pressure than pure rhodium alone. These alloys frequently offer a more optimized balance of performance and cost for general high-temperature heating.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its specific properties with your primary operational goal.

- If your primary focus is maximum temperature in an inert atmosphere or high-purity environment: Pure rhodium is an excellent candidate due to its exceptional melting point and elemental simplicity.

- If your primary focus is long-term stability and oxidation resistance in air: A platinum-rhodium alloy often provides superior durability and is the standard for many industrial furnace elements.

Ultimately, choosing the right material is about understanding the precise demands of your high-temperature process.

Summary Table:

| Property | Benefit for Heating Elements |

|---|---|

| High Melting Point (1960°C) | Provides wide operating temperature range, preventing melting |

| Superior Hot Strength | Resists deformation and sagging under thermal stress |

| High Grain Growth Temperature | Maintains structural integrity, reducing brittleness and failure |

| Low Vapor Pressure | Minimizes material loss through evaporation for long lifespan |

| Stable Oxide Evaporation | Prevents scale buildup, ensuring reliable performance |

Need a reliable high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced heating systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to your unique experimental needs, ensuring purity and durability in demanding environments. Contact us today to enhance your lab's performance with our expertise!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production