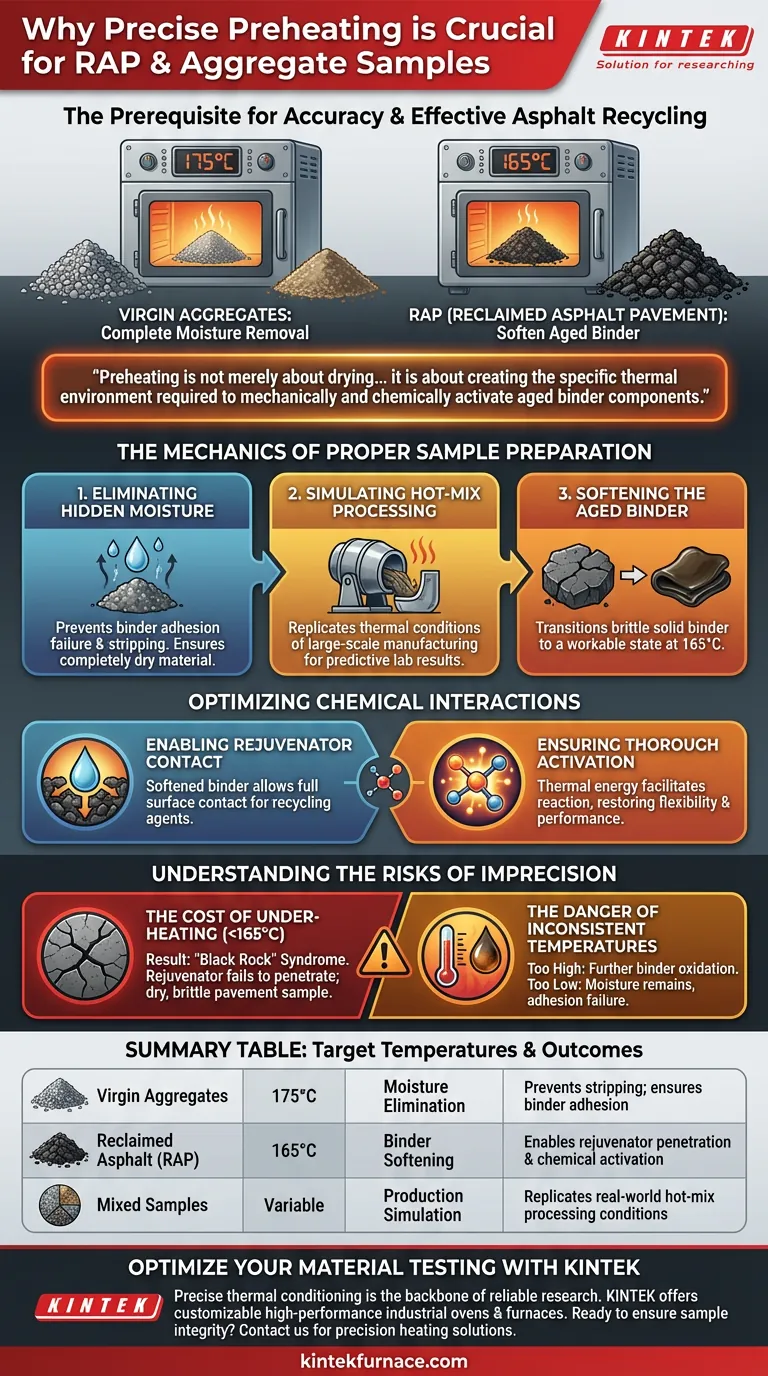

Precise preheating is the prerequisite for accurate material characterization and effective asphalt recycling. By using an industrial oven to achieve exact temperatures—specifically 175°C for aggregates and 165°C for Reclaimed Asphalt Pavement (RAP)—you ensure two critical outcomes: the complete removal of moisture and the necessary softening of aged asphalt binder to simulate real-world hot-mix processing.

Preheating is not merely about drying material; it is about creating the specific thermal environment required to mechanically and chemically activate aged binder components. Without this thermal precision, rejuvenators cannot effectively penetrate the material, compromising the integrity of the sample and the validity of any subsequent performance testing.

The Mechanics of Proper Sample Preparation

To understand why precision matters, you must look beyond the simple application of heat. The industrial oven acts as a simulation chamber for the harsh conditions found in asphalt production plants.

Eliminating Hidden Moisture

The first function of preheating is the removal of moisture from both virgin aggregates and RAP materials.

Moisture trapped within the aggregate structure can prevent the asphalt binder from adhering properly. By maintaining a controlled environment, you ensure that the material is completely dry before mixing begins.

Simulating Hot-Mix Processing

Laboratory results are only valuable if they predict field performance.

To achieve this, the sample preparation must replicate the thermal conditions of hot-mix processing. Precise temperature control allows the lab technician to mimic the specific heat profiles the material will encounter during large-scale manufacturing.

Softening the Aged Binder

RAP contains asphalt binder that has hardened and oxidized over time.

Before this material can be reused effectively, that hardened binder must be physically softened. Achieving the target temperature of 165°C for RAP is essential to transition the binder from a brittle solid to a workable state.

Optimizing Chemical Interactions

The most sophisticated aspect of preheating involves the chemistry of recycling. The goal is not just to melt the old asphalt, but to revitalize it.

Enabling Rejuvenator Contact

When introducing recycling agents or rejuvenators, the physical state of the old binder is the limiting factor.

If the RAP is not heated precisely to the target temperature, the binder remains too stiff. Proper preheating softens the aged asphalt enough to allow the rejuvenator to achieve full surface contact.

Ensuring Thorough Activation

Contact alone is not enough; the rejuvenator must integrate with the old asphalt.

The heat provided by the industrial oven facilitates the reaction between the additive and the aged binder. This thermal energy ensures the rejuvenator thoroughly activates the aged components, restoring flexibility and performance to the mix.

Understanding the Risks of Imprecision

While the primary reference highlights the necessity of precision, it is important to understand the consequences of failing to maintain these standards.

The Cost of Under-heating

If the oven fails to reach or maintain 165°C for RAP, the binder will not soften adequately.

This leads to "black rock" syndrome, where the RAP acts like aggregate rather than contributing binder to the mix. The rejuvenator will fail to penetrate, resulting in a dry, brittle pavement sample that underestimates the mix's potential.

The Danger of Inconsistent Temperatures

Industrial ovens are specified because standard ovens may fluctuate.

If temperatures drift too high, you risk further oxidizing the already aged binder, skewing your data. If they drift too low, moisture remains, causing stripping and adhesion failure in the final sample.

Making the Right Choice for Your Goal

Achieving a representative sample requires strictly adhering to temperature protocols based on your specific material objectives.

- If your primary focus is moisture elimination: Ensure your aggregates reach the higher threshold of 175°C to drive out pore water that disrupts adhesion.

- If your primary focus is RAP efficiency: Prioritize the 165°C setpoint to ensure the aged binder is soft enough to fully absorb and react with rejuvenators.

Consistency in your thermal conditioning process is the single most effective way to ensure your laboratory designs translate successfully to the roadway.

Summary Table:

| Material Type | Target Temperature | Primary Objective | Key Outcome |

|---|---|---|---|

| Virgin Aggregates | 175°C | Moisture Elimination | Prevents stripping; ensures binder adhesion |

| Reclaimed Asphalt (RAP) | 165°C | Binder Softening | Enables rejuvenator penetration & chemical activation |

| Mixed Samples | Variable | Production Simulation | Replicates real-world hot-mix processing conditions |

Optimize Your Material Testing with KINTEK

Precise thermal conditioning is the backbone of reliable asphalt recycling research. At KINTEK, we understand that even a minor temperature fluctuation can compromise your data. Backed by expert R&D and manufacturing, KINTEK offers high-performance industrial ovens and lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique asphalt and aggregate testing standards.

Ready to ensure the integrity of your samples? Contact us today to discover how our precision heating solutions can enhance your laboratory's efficiency and accuracy.

Visual Guide

References

- Peyman Sadeghi, Elham H. Fini. Carbon Sequestration via Bituminous Composites Containing Recycled High-Density Polyethylene. DOI: 10.3390/jcs8030100

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a vacuum oven required during the preparation of Al-CNTs/h-BN composites? Prevent Defects & Ensure Purity

- What are the key considerations when choosing a continuous furnace? Optimize Your High-Volume Production

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- What are the technical advantages of using a six-zone resistance heating furnace in VGF-VB? Unlock Precision Growth

- What are the advantages of using an optical floating zone furnace for VNbMoTaW? Achieve Ultra-High Purity Homogenization

- What is the role of a Pulsed Laser Deposition (PLD) system in orthopyroxene Fe-Mg experiments? Precision Film Growth

- How do industrial cameras and CNN improve surface defect detection? Revolutionize QC with 95%+ Accuracy

- What role does Sodium Chloride (NaCl) play as a thermal buffer? Optimizing Si/Mg2SiO4 Composite Synthesis