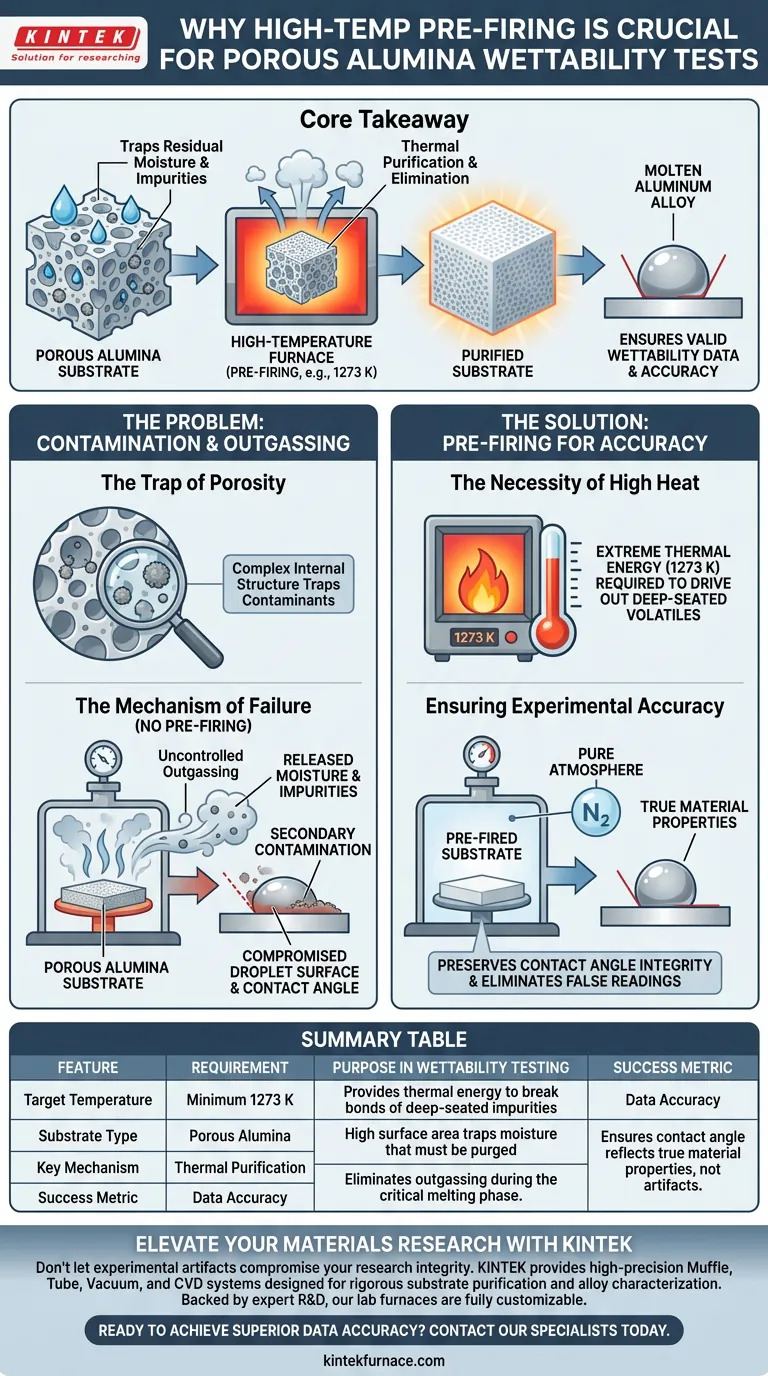

The use of a high-temperature furnace to pre-fire porous alumina substrates is a mandatory purification step required to ensure the validity of wettability data. This thermal treatment, often conducted at temperatures such as 1273 K, is the only effective method to completely eradicate residual moisture and latent impurities trapped within the ceramic's porous structure. Without this preliminary purge, these contaminants would be released during the experiment, compromising the chemical environment and the integrity of the aluminum alloy droplet.

Core Takeaway The primary function of pre-firing is to prevent outgassing during the testing phase. By eliminating moisture and impurities beforehand, you avoid secondary contamination of the experimental atmosphere and the droplet surface, ensuring that your wettability measurements reflect the true properties of the materials rather than experimental artifacts.

The Physics of Contamination in Porous Ceramics

The Trap of Porosity

Porous alumina substrates naturally possess a high surface area and a complex internal structure. While beneficial for certain applications, this structure acts as a trap for environmental contaminants.

Residual Moisture and Impurities

The most common contaminants are residual moisture absorbed from the air and volatile impurities left over from manufacturing or handling. These substances are often lodged deep within the pores, making them impossible to remove through simple surface cleaning or low-temperature drying.

The Necessity of High Heat

To fully drive out these trapped volatiles, extreme thermal energy is required. A high-temperature furnace setting, specifically around 1273 K, provides the energy necessary to break the bonds holding these impurities and force them out of the substrate completely.

The Mechanism of Failure: Outgassing

Uncontrolled Release

If a substrate is not pre-fired, the high temperatures required to melt the aluminum alloy during the actual test will inadvertently trigger the purification process. The trapped moisture and impurities will vaporize and expand, exiting the pores in a phenomenon known as outgassing.

Secondary Contamination

This released gas does not simply disappear; it enters the immediate experimental environment. This results in secondary contamination of the testing atmosphere, which is often a carefully controlled vacuum or inert gas environment.

Compromising the Droplet Surface

Most critically, the outgassed vapors interact directly with the molten aluminum droplet. This interaction alters the surface chemistry of the droplet, leading to oxidation or other reactions that fundamentally change how the liquid interacts with the solid substrate.

Ensuring Experimental Accuracy

Preserving Contact Angle Integrity

Wettability is characterized by measuring the contact angle of the droplet on the substrate. This measurement is highly sensitive to surface tension and chemical homogeneity.

Eliminating False Readings

Any contamination of the droplet surface introduces variables that distort the contact angle. By pre-firing the substrate, you ensure that the observed wetting behavior is intrinsic to the alloy and the alumina, guaranteeing the accuracy of the measurement results.

Common Pitfalls to Avoid

Insufficient Temperature

Pre-firing at temperatures significantly lower than 1273 K may fail to remove all deep-seated impurities. Partial removal can be deceptive, as outgassing may still occur once the experimental temperature rises, ruining the data during the critical melting phase.

Ignoring the Timeline

Pre-firing should be viewed as an immediate precursor to testing. Allowing a pre-fired porous substrate to sit exposed to ambient air for extended periods allows it to re-absorb moisture, negating the benefits of the furnace treatment.

Making the Right Choice for Your Experiment

To ensure your wettability characterization yields publishable, reliable data, adhere to the following protocols:

- If your primary focus is Data Accuracy: Ensure your furnace protocol reaches at least 1273 K to guarantee the total elimination of deep-seated moisture.

- If your primary focus is Atmosphere Control: Recognize that substrate outgassing is a leading cause of vacuum degradation; pre-firing is the primary defense against this.

Ultimately, high-temperature pre-firing is not merely a cleaning step; it is a fundamental control ensuring that your results measure the material, not the moisture.

Summary Table:

| Feature | Requirement | Purpose in Wettability Testing |

|---|---|---|

| Target Temperature | Minimum 1273 K | Provides thermal energy to break bonds of deep-seated impurities |

| Substrate Type | Porous Alumina | High surface area traps moisture that must be purged |

| Key Mechanism | Thermal Purification | Eliminates outgassing during the critical melting phase |

| Success Metric | Data Accuracy | Ensures contact angle reflects true material properties, not artifacts |

Elevate Your Materials Research with KINTEK

Don't let experimental artifacts compromise your research integrity. KINTEK provides high-precision Muffle, Tube, Vacuum, and CVD systems designed to meet the rigorous thermal demands of substrate purification and alloy characterization. Backed by expert R&D and manufacturing, our lab high-temp furnaces are fully customizable to your specific heating profiles.

Ready to achieve superior data accuracy?

Contact our specialists today to find your custom furnace solution.

Visual Guide

References

- Chukwudalu Uchenna Uba, Jonathan Raush. Quantification of Wettability and Surface Tension of Liquid Aluminum 7075 Alloy on Various Substrates. DOI: 10.3390/jmmp9050165

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of the atmosphere control system in a program-controlled atmosphere furnace? Master Precision and Protection

- Why is temperature precision in industrial high-temperature furnaces critical for biomass thermochemical conversion?

- How does the design of a convector plate affect the thermal efficiency? Maximize Bell-Type Annealing Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does a periodic resistance furnace improve High Vanadium High Speed Steel annealing? Enhance Machinability Today

- What safety considerations are important when operating atmosphere furnaces? Ensure Explosion-Free Operation with Expert Tips

- What is the primary function of the circulation fan in a full-hydrogen bell-type furnace? Boost Heat Transfer Efficiency

- Which industries commonly use atmosphere furnaces? Unlock Precision in High-Temp Processing