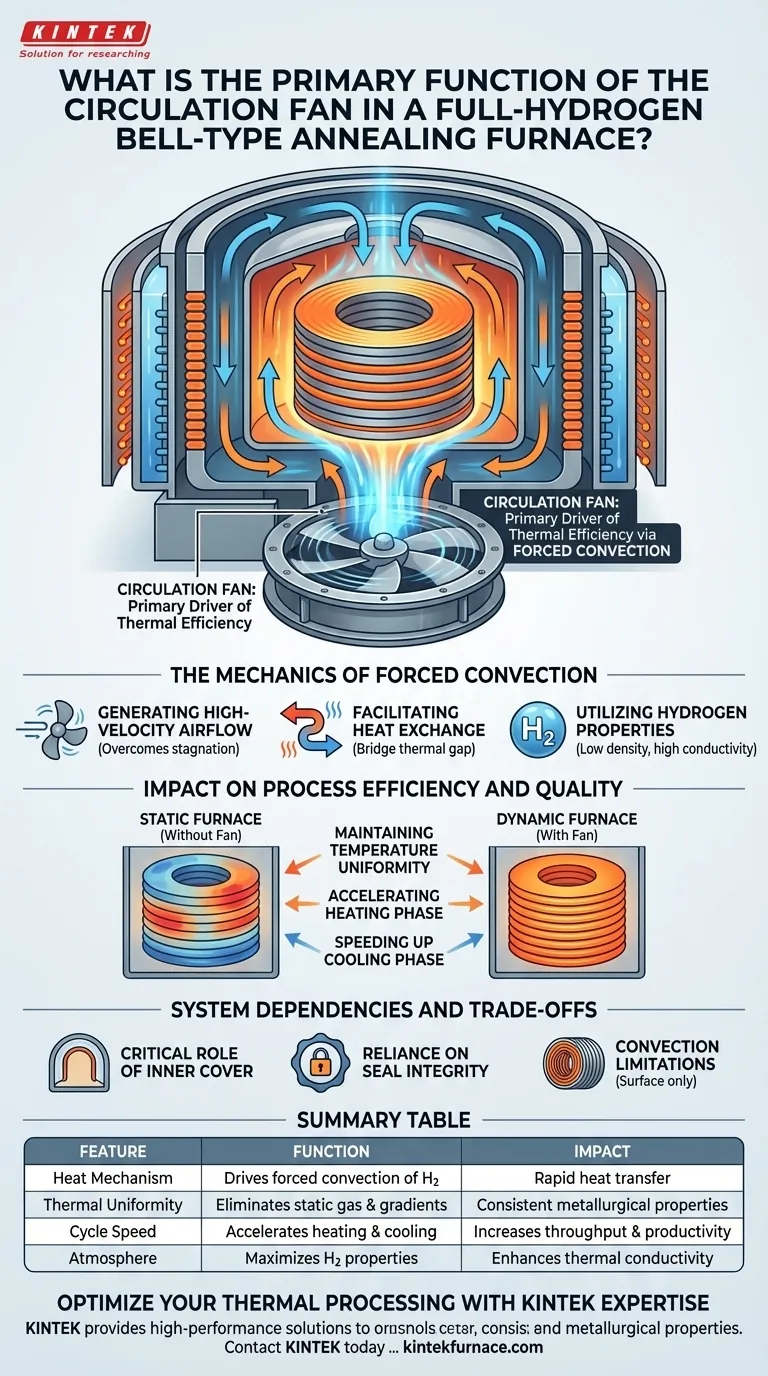

The circulation fan is the primary driver of thermal efficiency in a full-hydrogen bell-type annealing furnace. Its specific function is to force the high-speed circulation of protective gases, such as high-purity hydrogen, creating a dynamic environment within the sealed inner cover. This movement generates forced convection, which is the critical mechanism for transferring heat rapidly and evenly between the heat source and the steel coils.

By transforming the protective atmosphere from a static gas into a dynamic thermal medium, the circulation fan eliminates temperature gradients and significantly reduces cycle times for both heating and cooling.

The Mechanics of Forced Convection

Generating High-Velocity Airflow

The fan operates by mechanically driving the protective gas—typically high-purity hydrogen—at high speeds. This overcomes the natural tendency of gases to stagnate, which would otherwise act as thermal insulators.

Facilitating Heat Exchange

The core role of this circulation is to bridge the thermal gap between the heat source and the workload. The fan moves heated gas from the inner cover's surface directly to the steel coils, ensuring efficient energy transfer.

Utilizing Hydrogen Properties

Hydrogen is chosen for its low density and high thermal conductivity. The fan exploits these properties, moving the gas rapidly to maximize the rate at which heat is absorbed or dissipated by the metal.

Impact on Process Efficiency and Quality

Maintaining Temperature Uniformity

A static furnace inevitably develops hot and cold spots. The circulation fan ensures a uniform temperature field throughout the furnace, guaranteeing that every part of the steel coil receives the exact same heat treatment.

Accelerating the Heating Phase

Through forced convection, the system brings the steel coils to the required soaking temperature much faster than radiation alone could achieve. This directly translates to higher throughput and productivity.

Speeding Up the Cooling Phase

The fan is equally critical after the soak time is complete. It actively moves heat away from the hot coils to the inner cover walls, where external cooling methods (air or water spray) dissipate the energy.

System Dependencies and Trade-offs

The Critical Role of the Inner Cover

The fan does not operate in isolation; it functions within the strict confines of the inner cover. As noted in your supplementary context, this cover acts as both a physical barrier and a heat transfer intermediary.

Reliance on Seal Integrity

Because the fan circulates the atmosphere at high speeds, the integrity of the inner cover's seal is paramount. If the seal fails, the fan will effectively circulate contaminants, destroying the high-reduction environment required for clean annealing.

Convection Limitations

While the fan maximizes external heat transfer, it cannot force gas between the tight layers of a steel coil. The heat must still conduct through the metal itself, meaning the fan maximizes surface exposure but cannot overcome poor coil winding or stacking.

Making the Right Choice for Your Goal

To optimize the performance of your annealing furnace, you must view the circulation fan as the heartbeat of the thermal cycle.

- If your primary focus is increasing throughput: Prioritize high-performance fans that can maximize convection velocity to shorten both heating and cooling ramp times.

- If your primary focus is metallurgical consistency: Ensure your fan operation is calibrated to maintain perfect thermal uniformity, eliminating the risk of uneven mechanical properties in the steel.

The circulation fan transforms the protective atmosphere from a passive chemical shield into an active, high-velocity tool for precise thermal management.

Summary Table:

| Feature | Function of Circulation Fan | Impact on Process |

|---|---|---|

| Heat Mechanism | Drives forced convection of hydrogen gas | Rapid heat transfer between source and coils |

| Thermal Uniformity | Eliminates static gas and temperature gradients | Ensures consistent metallurgical properties |

| Cycle Speed | Accelerates both heating and cooling phases | Increases furnace throughput and productivity |

| Atmosphere | Maximizes high-purity hydrogen properties | Enhances thermal conductivity and surface finish |

Optimize Your Thermal Processing with KINTEK Expertise

Don't let inefficient heat transfer limit your productivity. KINTEK provides high-performance high-temperature solutions backed by expert R&D and manufacturing. Our systems, including Muffle, Tube, Rotary, Vacuum, and CVD furnaces, are fully customizable to meet your unique laboratory and industrial requirements.

Whether you need to enhance temperature uniformity or accelerate cooling cycles, our engineers are ready to help you achieve superior results. Contact KINTEK today to discuss your customized furnace needs and see how our advanced thermal technology can empower your next project.

Visual Guide

References

- Yang Xiao-jing, Yu-Ren Li. Study of heat transfer model and buried thermocouple test of bell-type annealing furnace based on thermal equilibrium. DOI: 10.1038/s41598-025-97422-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What challenges are associated with inert atmosphere furnaces? Overcome High Costs and Complexity

- Why must the carbonization of coffee-based bio-adsorbents be performed in a nitrogen furnace? Expert Guide

- What role do atmosphere furnaces play in new energy material R&D? Unlock Precision Synthesis for Batteries and Solar Cells

- What core processing conditions does a tube atmosphere furnace provide? Key Factors for fMC Carbonization

- Why are sealing mechanisms critical in atmosphere furnaces? Ensure Purity, Safety, and Efficiency

- How does a heating furnace contribute to the simulated pre-oxidation of alloy powders? Optimize Your Material Research

- What are the technical advantages of using high-purity hydrogen for Cu-Al2O3 sintering? Enhance Bonding & Conductivity

- What are the characteristics and applications of exothermic atmospheres in furnaces? Optimize Metal Heat Treatment