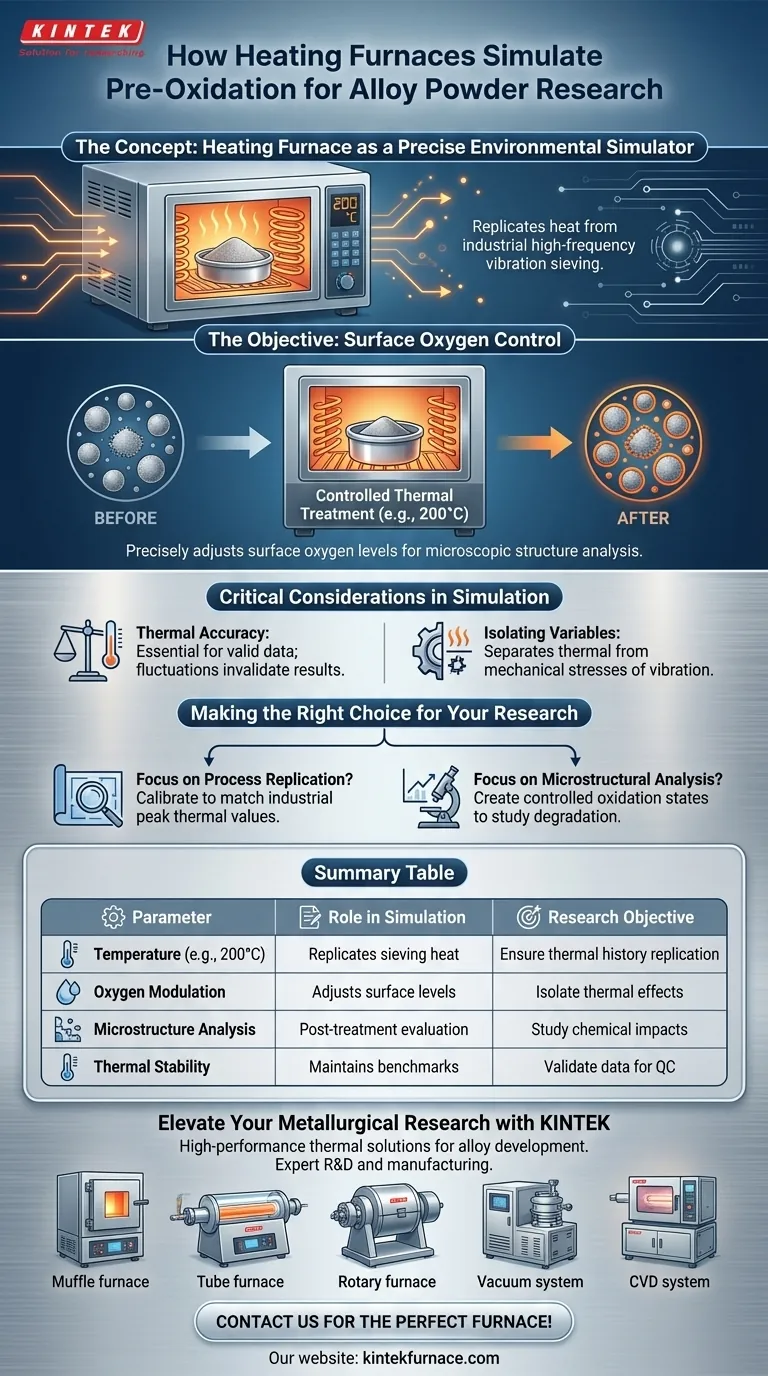

In metallurgical research, a heating furnace acts as a precise environmental simulator designed to induce specific pre-oxidation states in alloy powders. By subjecting the powder to controlled thermal treatment—specifically at temperatures such as 200 degrees Celsius—the furnace replicates the heat naturally generated during industrial high-frequency vibration sieving. This process allows researchers to deliberately adjust surface oxygen levels to analyze their specific effects on the alloy's microscopic structure.

The heating furnace serves as a controlled proxy for industrial processing, isolating the thermal variable to precisely modulate surface oxygen. This enables the detailed study of how oxidation impacts the fundamental microstructure of alloy powders.

Replicating Industrial Thermal Conditions

Simulating Vibration Sieving Heat

In industrial settings, the process of high-frequency vibration sieving generates significant friction and heat. The heating furnace allows researchers to replicate this specific temperature rise in a static, controlled laboratory setting without needing to run full-scale sieving equipment.

Precise Temperature Targeting

To ensure the simulation is accurate, the furnace is set to specific thermal benchmarks, such as 200 degrees Celsius. This capability ensures that the alloy powder experiences the exact thermal history it would undergo during actual manufacturing processes.

The Objective: Surface Oxygen Control

Modulating Oxidation Levels

The core purpose of this thermal treatment is the precise adjustment of oxygen levels on the powder's surface. By controlling the duration and intensity of the heat, researchers can dictate exactly how much oxidation occurs.

Analyzing Microscopic Structure

Once the pre-oxidation is complete, the focus shifts to material analysis. Researchers study the treated powder to understand how these specific oxygen levels influence the microscopic structure of the alloy, providing data critical for quality control and material development.

Critical Considerations in Simulation

The Importance of Thermal Accuracy

The validity of this research depends entirely on the stability of the furnace. If the temperature fluctuates away from the target (e.g., 200°C), the oxygen levels will not accurately reflect the industrial sieving process, rendering the data invalid.

Isolating Variables

It is important to recognize that the furnace isolates the thermal aspect of sieving. While it effectively simulates the temperature rise and subsequent oxidation, it separates these chemical changes from the mechanical physical stresses of vibration.

Making the Right Choice for Your Research

To effectively utilize a heating furnace for alloy powder analysis, align your approach with your specific research goals:

- If your primary focus is process replication: Calibrate the furnace temperature to match the exact peak thermal values recorded during your specific industrial sieving operations.

- If your primary focus is microstructural analysis: Use the furnace to create a controlled series of oxidation states to identify exactly where oxygen levels begin to degrade or alter the alloy's structure.

Controlled heat is the key to unlocking the relationship between processing conditions and material integrity.

Summary Table:

| Parameter | Role in Simulation | Research Objective |

|---|---|---|

| Temperature (e.g., 200°C) | Replicates heat from high-frequency vibration sieving | Ensure accurate thermal history replication |

| Oxygen Modulation | Adjusts surface oxygen levels via controlled oxidation | Isolate thermal effects on powder surface |

| Microstructure Analysis | Post-treatment material evaluation | Study chemical impacts on alloy integrity |

| Thermal Stability | Maintains precise environmental benchmarks | Validate data for industrial quality control |

Elevate Your Metallurgical Research with KINTEK

Precision is the foundation of material science. KINTEK provides high-performance thermal solutions designed to meet the rigorous demands of alloy development. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to your specific research parameters.

Whether you are simulating industrial sieving conditions or conducting deep-dive microstructural analysis, KINTEK’s equipment ensures the thermal accuracy you need for reproducible results. Contact us today to find the perfect furnace for your laboratory!

Visual Guide

References

- Yufeng Liu, Guoqing Zhang. Effects of Oxygen Content on Microstructure and Creep Property of Powder Metallurgy Superalloy. DOI: 10.3390/cryst14040358

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature argon atmosphere sintering furnace play in the production of 316L? Master Metallurgy

- What are the safety and operational requirements for box furnaces and atmosphere furnaces? Ensure Safe, Efficient Heat Treatment

- How does an industrial high-temperature furnace simulate the blast furnace reduction environment? Achieve 30% Reduction

- Why are continuous controlled atmosphere furnaces critical for MIM steel parts? Achieve High-Density Sintering

- What is the significance of atmosphere control and the heating ramp rate in a reduction furnace for Ni-WOx catalysts?

- How does the box type annealing atmosphere furnace improve material quality? Enhance Strength, Ductility, and Surface Integrity

- What are the controlled atmospheres for heat treatment? Master the Art of Material Transformation

- What are sealed atmosphere furnaces called and what are their features? Discover Precision Heat Treatment Solutions