In short, the safety and operational requirements for a box furnace are straightforward, focusing on basic high-temperature and electrical protection. An atmosphere furnace, however, has far more stringent requirements due to its use of potentially flammable and explosive gases, demanding specialized gas monitoring, explosion-proof systems, and highly trained operators.

The core difference is not the heat, but the air inside. A box furnace operates in ambient air, making its safety protocols simple. An atmosphere furnace replaces that air with a controlled gas, introducing significant risks that dictate every aspect of its design, safety, and operation.

The Fundamental Difference: Operating Atmosphere

The operational environment inside the furnace is the single most important factor determining its safety and complexity. This dictates the furnace's entire design philosophy.

Box Furnaces: Simplicity in Air

A box furnace is fundamentally a high-temperature chamber that operates in a natural air environment. Its structure is relatively simple, with basic sealing on the furnace door.

This design is ideal for conventional heat treatment processes like annealing, tempering, or drying, where material oxidation from the air is either acceptable or desired.

Atmosphere Furnaces: Precision Under Control

An atmosphere furnace is designed to replace the air with a specific, controlled gas. This can be a protective gas like nitrogen or an inert gas to prevent oxidation, or a reactive gas like hydrogen for a reducing environment.

This capability is essential for processing oxidation-sensitive metals (like titanium alloys), powder metallurgy, and special processes like carburization. To achieve this, the furnace requires a highly sealed structure, complete with dedicated gas inlet/outlet systems and pressure controls.

Core Safety Requirements Compared

While both furnaces deal with extreme heat, the introduction of specialized gases in an atmosphere furnace creates an entirely different class of risk.

For All Furnaces: Managing Heat and Electricity

Both furnace types must have foundational safety systems to manage the inherent risks of high temperatures.

These include alarms and automatic shutdowns for overheating, underheating, and thermocouple breaks. A double-layered shell with high-grade insulation is standard, ensuring the external surface remains cool enough to prevent operator burns.

For Atmosphere Furnaces: Managing Gas and Explosion Risk

Atmosphere furnaces require all the basic protections plus a suite of advanced systems to manage gas-related hazards. The risk is no longer just a burn, but a potential fire, explosion, or asphyxiation.

Key additional requirements include:

- Gas Monitoring Systems: To continuously check for leaks and ensure the correct atmospheric composition.

- Explosion-Proof Devices: Such as pressure relief valves and flame arrestors, especially when using flammable gases like hydrogen.

- Strict Sealing: To prevent hazardous gas from leaking out or oxygen from leaking in, which could create an explosive mixture.

Operational Protocols: A Tale of Two Complexities

The difference in complexity is most apparent in the day-to-day operational procedures and the level of skill required.

Operating a Box Furnace

The operation is direct and requires minimal specialized training. An operator typically sets the target temperature and time, loads the material, and waits for the cycle to complete while observing basic high-temperature precautions.

Operating an Atmosphere Furnace

Operating an atmosphere furnace is a multi-step, high-stakes process that demands a professionally trained operator.

Protocols involve not just setting temperature but also purging the chamber of air, introducing the specific gas, maintaining precise atmospheric pressure and composition, and safely venting the gas post-cycle. Continuous monitoring and adherence to strict safety protocols are non-negotiable.

Understanding the Trade-offs: Cost vs. Capability

The choice between these furnaces comes down to a clear trade-off between process capability, cost, and complexity.

Structural and Cost Implications

A box furnace's simple structure makes it less expensive to manufacture and easier to maintain. Its low operational complexity translates to lower ongoing costs.

An atmosphere furnace's need for a perfectly sealed chamber, gas delivery systems, pressure controls, and advanced safety monitoring makes it significantly more complex and costly to build, install, and maintain.

Risk and Operator Skill

The primary risk with a box furnace is a thermal burn or electrical fault, which can be managed with standard industrial safety training.

The risks associated with an atmosphere furnace are far more severe. The need to handle flammable, explosive, or asphyxiating gases mandates a higher level of institutional safety culture and operators with specialized, certified training.

Making the Right Choice for Your Application

Your process requirements will dictate the necessary furnace type, but you must be prepared to meet the corresponding safety and operational demands.

- If your primary focus is general heat treatment in air (annealing, tempering, drying): A box furnace is the safe, simple, and cost-effective choice.

- If your primary focus is processing oxidation-sensitive materials or requires a specific chemical atmosphere: An atmosphere furnace is essential, but you must commit to the significant investment in advanced safety systems and rigorous operator training.

Ultimately, your material and process goals determine the furnace, but the safety protocols associated with that choice are absolute.

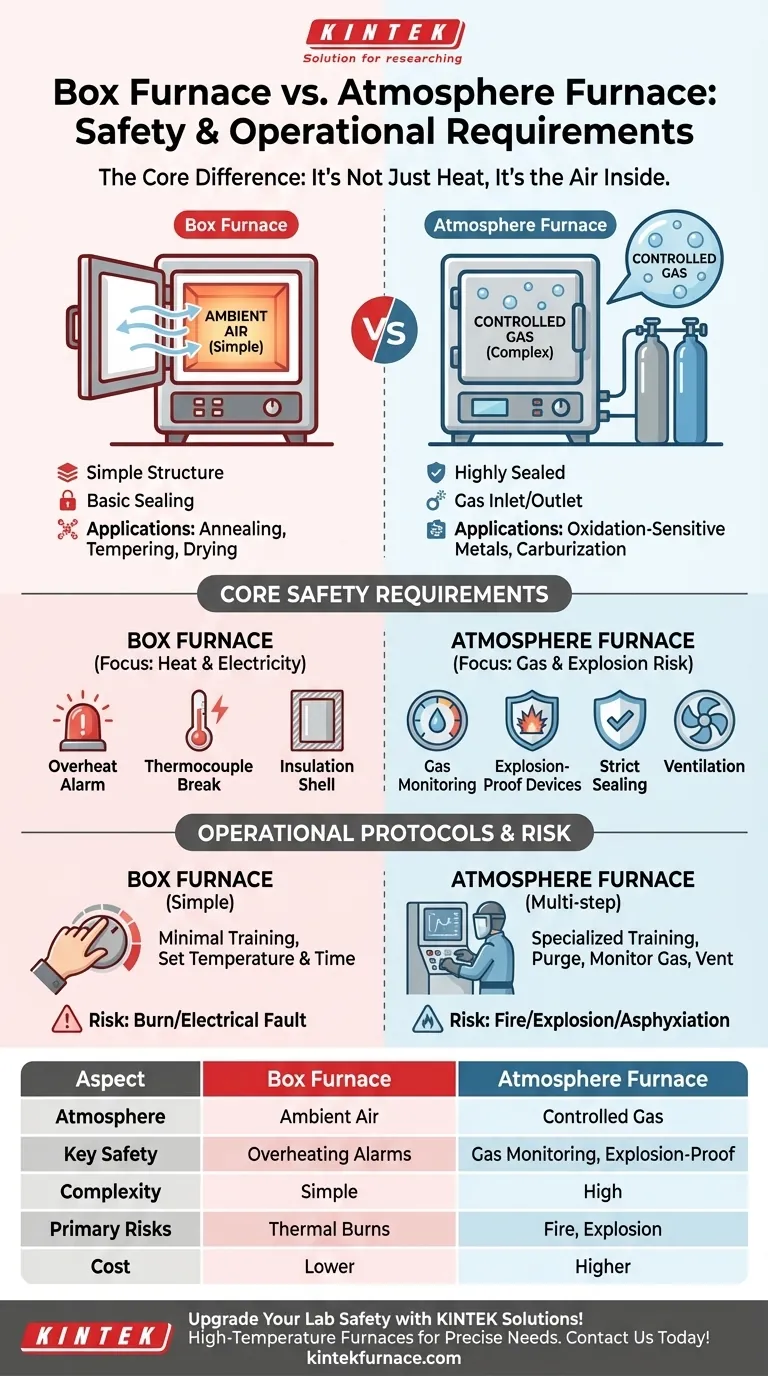

Summary Table:

| Aspect | Box Furnace | Atmosphere Furnace |

|---|---|---|

| Operating Atmosphere | Ambient air | Controlled gas (e.g., nitrogen, hydrogen) |

| Key Safety Features | Overheating alarms, insulation | Gas monitoring, explosion-proof systems, strict sealing |

| Operational Complexity | Simple, minimal training | High, requires specialized training and multi-step protocols |

| Primary Risks | Thermal burns, electrical faults | Fire, explosion, asphyxiation |

| Ideal Applications | Annealing, tempering, drying in air | Oxidation-sensitive materials, powder metallurgy, carburization |

Upgrade your laboratory's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong customization capabilities ensure precise solutions for your unique experimental needs. Contact us today to discuss how our furnaces can enhance your processes and safety protocols!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What critical protective roles does argon serve for AA7150-Al2O3 composites? Ensure Purity & Density

- Why must the carbonization of coffee-based bio-adsorbents be performed in a nitrogen furnace? Expert Guide

- What is the primary role of the furnace atmosphere in material processing? Control Chemical Reactions for Superior Results

- What is the primary function of an air oxidation furnace in carbon chain synthesis? Optimize SWCNT Pretreatment

- How is a controlled atmosphere furnace used in material research? Achieve Precise Material Synthesis and Heat Treatment

- What are the working principles and gas environments of box furnaces and atmosphere furnaces? Choose the Right Furnace for Your Lab

- How does an atmosphere furnace benefit the metallurgy industry? Enhance Material Quality and Efficiency

- Why is a high-precision furnace essential for CZTSSe thin films? Prevent Phase Decomposition and Amorphization