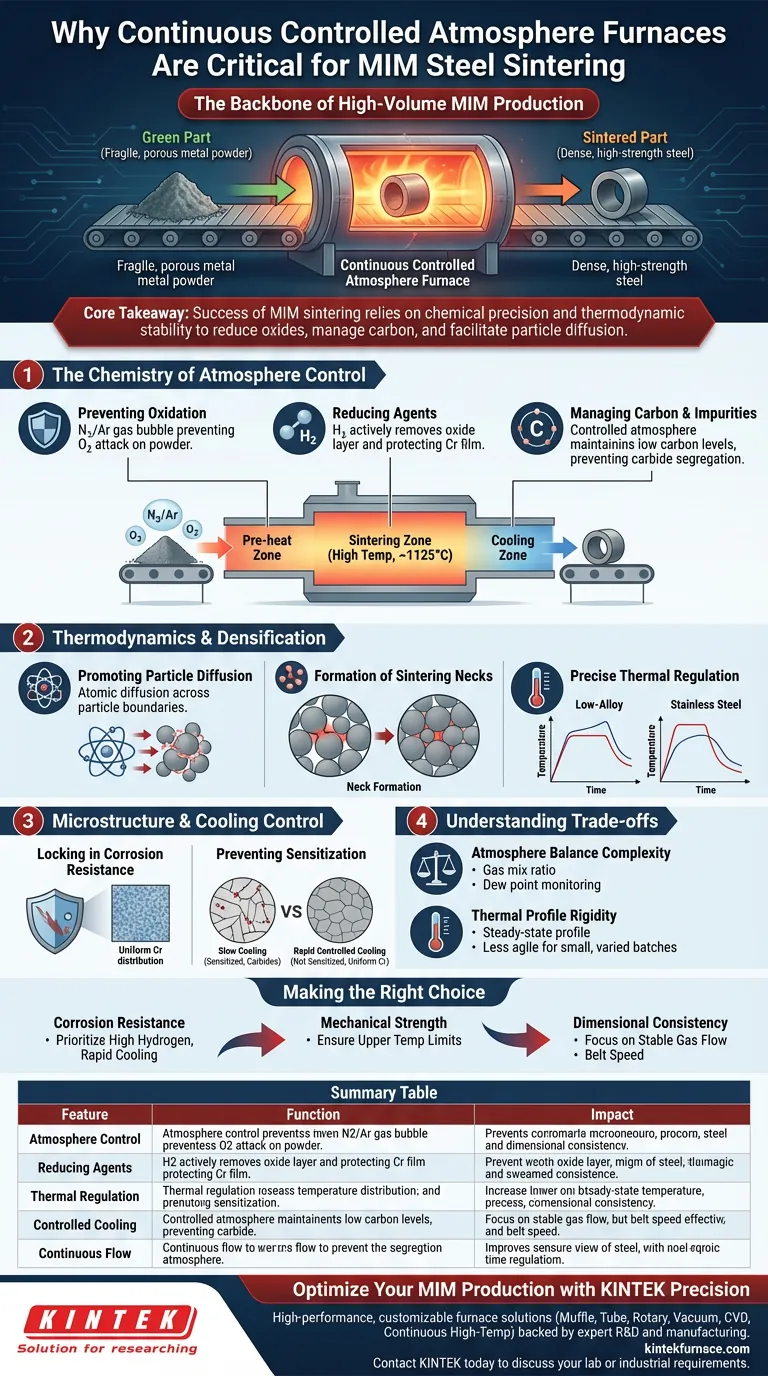

Continuous controlled atmosphere furnaces are the backbone of high-volume MIM production because they create a chemically active, stable environment that transforms fragile "green" parts into dense, high-strength steel components. By precisely regulating gas composition (typically nitrogen, hydrogen, or argon) and temperature profiles, these furnaces prevent oxidation and drive the essential diffusion mechanisms required for densification.

Core Takeaway The success of MIM sintering relies not just on heat, but on chemical precision. Continuous controlled atmosphere furnaces provide the necessary thermodynamic stability to reduce oxides, manage carbon content, and facilitate particle diffusion, ensuring the mechanical integrity and corrosion resistance of the final alloy.

The Chemistry of Atmosphere Control

Preventing Oxidation at the Source

The primary function of these furnaces is to isolate metal powders from oxygen. High temperatures naturally accelerate oxidation, which acts as a barrier to particle bonding. By utilizing gases like nitrogen or high-purity argon, the furnace creates a protective shield that prevents the metal powder from degrading during the heating process.

The Role of Reducing Agents

Protection alone is often insufficient; active reduction is required. Atmospheres containing hydrogen provide a strong reducing potential. This chemically removes residual oxygen from the powder surface and protects the chromium oxide passivation film on stainless steels, preventing thermal degradation.

Managing Carbon and Impurities

The atmosphere is critical for controlling the chemical composition of the steel. A controlled environment helps maintain extremely low carbon levels by addressing excess carbon caused by binder residues. This prevents carbide segregation, which is vital for maintaining the mechanical integrity of the part.

Thermodynamics and Densification

Promoting Particle Diffusion

Sintering is fundamentally about moving atoms to close pores. The stable thermal environment provided by continuous furnaces promotes diffusion, where atoms move across particle boundaries. This movement is essential for the densification of the powder mass into a solid part.

Formation of Sintering Necks

The combination of high heat (e.g., 1125°C for steel) and a reducing atmosphere facilitates the formation of sintering necks. These are the physical bridges that form between individual metal particles. As these necks grow, the material density increases, directly enhancing the overall mechanical strength of the component.

Precise Thermal Regulation

Different alloys have specific thermodynamic requirements. Continuous furnaces allow for precise temperature regulation—such as specific set points for low-alloy vs. stainless steels—to optimize the sintering outcome. This ensures that electrical and thermal conductivity characteristics are determined by the material properties, not by defects like porosity.

Microstructure and Cooling Control

Locking in Corrosion Resistance

For stainless steel MIM parts, the cooling phase is as critical as the heating phase. Continuous furnaces with controlled cooling zones dictate the microstructural evolution of the steel.

Preventing Sensitization

Rapid, controlled cooling kinetics inhibit the precipitation of intergranular carbides, a phenomenon known as sensitization. By preventing this, the furnace ensures that chromium remains uniformly distributed within the metal matrix. This uniformity is non-negotiable for achieving superior corrosion resistance.

Understanding the Trade-offs

Complexity of Atmosphere Balance

While continuous furnaces offer high throughput, maintaining the gas mix requires strict vigilance. A slight imbalance in the hydrogen-to-nitrogen ratio (e.g., deviating from a standard 90/10 mix) can lead to incomplete reduction or surface defects. The process requires constant monitoring of dew points and gas purity.

Thermal Profile Rigidity

Continuous furnaces rely on a steady-state thermal profile established along the belt or pusher path. Unlike batch vacuum furnaces, which can easily vary cycles per load, changing the profile in a continuous furnace is time-consuming. This makes them less agile for facilities processing small batches of vastly different alloys in rapid succession.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sintering process, align your furnace parameters with your specific metallurgical targets:

- If your primary focus is Corrosion Resistance (Stainless Steel): Prioritize an atmosphere with high hydrogen content and rapid cooling capabilities to prevent chromium carbide precipitation.

- If your primary focus is Mechanical Strength: Ensure your temperature profile reaches the upper limits of the alloy's sintering window (e.g., ~1125°C for steels) to maximize neck formation and densification.

- If your primary focus is Dimensional Consistency: Focus on the stability of gas flow and belt speed to ensure every part experiences the exact same thermodynamic history.

Ultimately, the furnace is not just a heat source; it is a chemical reactor that defines the final reality of your material.

Summary Table:

| Feature | Function in MIM Sintering | Impact on Final Part |

|---|---|---|

| Atmosphere Control | Uses Nitrogen, Hydrogen, or Argon to isolate oxygen | Prevents oxidation and ensures chemical purity |

| Reducing Agents | Hydrogen removes residual surface oxides | Enhances particle bonding and mechanical strength |

| Thermal Regulation | Precise, steady-state heat (e.g., 1125°C) | Facilitates neck formation and material densification |

| Controlled Cooling | Manages cooling kinetics post-sintering | Prevents sensitization and locks in corrosion resistance |

| Continuous Flow | High-volume throughput on belt or pusher paths | Ensures dimensional consistency and production efficiency |

Optimize Your MIM Production with KINTEK Precision

Don’t let oxidation or inconsistent thermal profiles compromise your steel components. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized continuous high-temp furnaces—all fully customizable to meet your unique metallurgical needs.

Whether you are aiming for superior corrosion resistance or maximum mechanical strength, our team is ready to help you engineer the perfect sintering environment. Contact KINTEK today to discuss your lab or industrial requirements and ensure every part meets the highest standard of excellence.

Visual Guide

References

- Jorge Luis Braz Medeiros, Luciano Volcanoglo Biehl. Effect of Sintering Atmosphere Control on the Surface Engineering of Catamold Steels Produced by MIM: A Review. DOI: 10.3390/surfaces9010007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why are high-temperature annealing furnaces and H2-N2 atmospheres required for oriented silicon steel research?

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What is a retort furnace and its primary function? Achieve High-Purity Thermal Processing in Sealed Environments

- How is a high-vacuum or atmosphere furnace utilized to control the structure of silicon nanowires? Expert Guide

- What is a controlled atmosphere lab furnace? Master Precise Material Processing and Avoid Oxidation

- What role does a high-temperature furnace play in uranyl silicate crystal growth? Master Precision Thermal Control

- How does the heating and cooling performance of box type atmosphere furnaces benefit production? Boost Throughput and Quality

- Why is the use of a programmable box furnace critical for the preparation of U0.92Mn3Si2C? Ensure Synthesis Precision