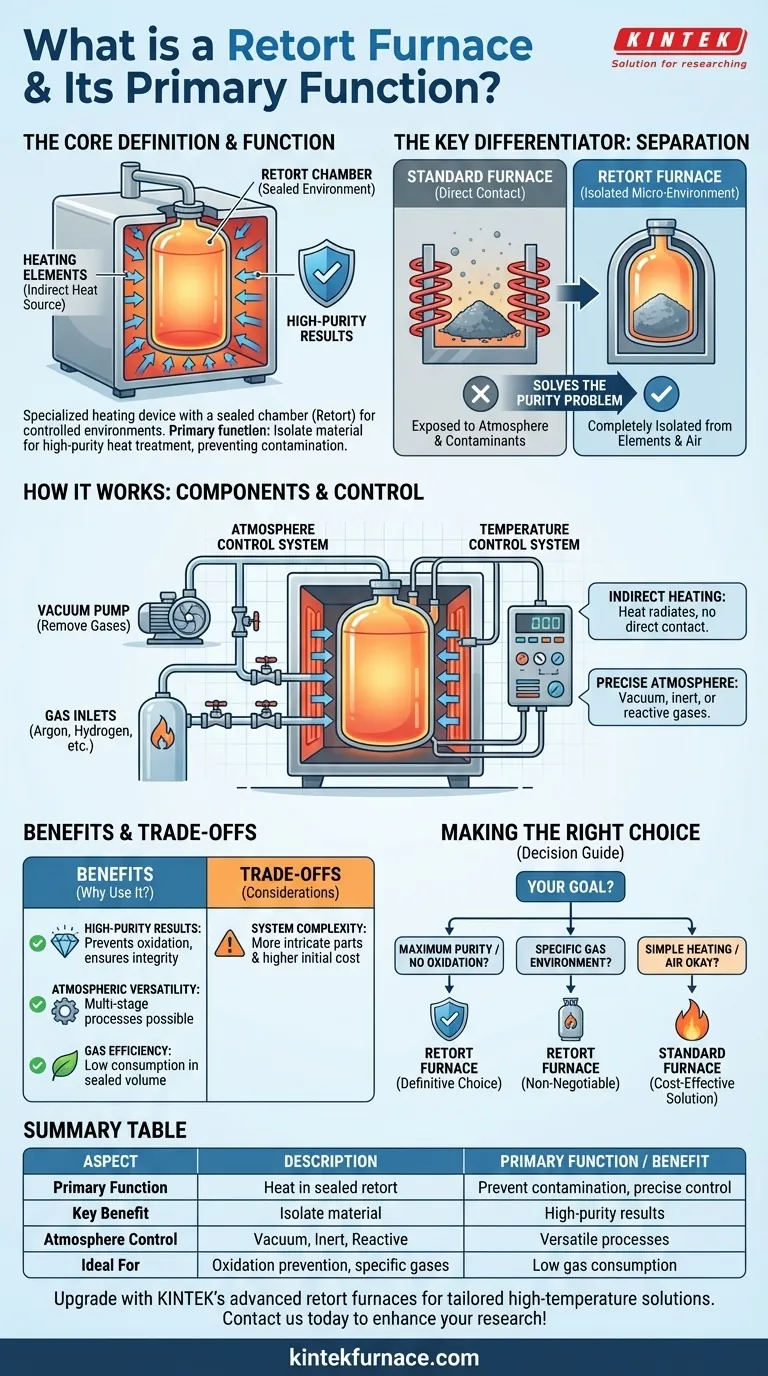

At its core, a retort furnace is a specialized heating device designed for thermal processes that demand a highly controlled environment. Its primary function is to heat materials within a sealed chamber, known as the retort, completely isolating the product from the furnace's heating elements and the outside air to prevent contamination and manage the atmospheric conditions precisely.

The fundamental difference between a standard furnace and a retort furnace is separation. By placing the material inside a sealed vessel (the retort), you create an isolated micro-environment, enabling high-purity heat treatment that is impossible in a furnace where the material is exposed to ambient air and direct heat.

How a Retort Furnace Solves the Purity Problem

The unique design of a retort furnace directly addresses the challenges of contamination, oxidation, and atmospheric inconsistency that can occur in conventional furnaces.

The Central Role of the Retort

The "retort" is the heart of the system. It is a sealed, and often cylindrical, vessel that holds the material being processed.

This chamber is placed inside the larger furnace structure, acting as a barrier between your product and the furnace's internal environment.

Isolating the Material from the Heat Source

Heating in a retort furnace is indirect. The furnace's heating elements warm the outside of the retort, and that heat radiates inward to process the material.

This prevents any direct contact between the material and the heating elements, which could otherwise be a source of contamination.

Achieving Precise Atmosphere Control

Because the retort is a sealed vessel, you have absolute authority over the atmosphere within it. This allows for several critical processes.

You can pull a vacuum to remove all reactive gases or introduce specific inert or reactive gases like Argon or Hydrogen to facilitate a particular chemical reaction or prevent an unwanted one, like oxidation.

Key Components and Their Function

A retort furnace is a system of integrated parts, each with a specific purpose designed to maintain control and purity.

The Retort Chamber

This is the central vessel where the material is placed. It is engineered to withstand extreme temperatures and maintain a perfect seal against pressure or vacuum.

Heating Elements

These are positioned outside the retort and are responsible for generating the heat. They are typically made from robust materials like graphite, ceramics, or specialized metal alloys.

Temperature Control System

This system uses thermocouples and sophisticated controllers to monitor and regulate the temperature with a high degree of precision, ensuring the process follows the exact desired thermal profile.

Atmosphere Control System

This system includes the pumps, valves, and gas inlets required to remove air from the retort and introduce and maintain the pressure of the specialized process gases.

Understanding the Trade-offs and Benefits

While powerful, a retort furnace is a specialized tool. Understanding its advantages and inherent complexities is key to using it effectively.

The Primary Benefit: High-Purity Results

The main advantage is the ability to produce exceptionally high-quality materials. By eliminating oxygen and other contaminants, the sealed retort prevents oxidation and ensures the final product's chemical integrity.

Benefit: Atmospheric Versatility

A retort furnace allows you to alter the atmospheric conditions during a single firing cycle. You can start in a vacuum, introduce one gas, and then switch to another, enabling highly complex, multi-stage processes.

Benefit: Gas Efficiency

Because you are only controlling the atmosphere within the relatively small, sealed retort, gas consumption is extremely low compared to attempting to purge the entire volume of a larger, unsealed furnace.

The Main Consideration: System Complexity

The primary trade-off is increased complexity. A retort furnace requires vacuum pumps, gas handling systems, and robust seals, making it a more intricate and often more expensive solution than a simple atmospheric furnace.

Making the Right Choice for Your Goal

Selecting the correct heating method depends entirely on the requirements of your material and process.

- If your primary focus is maximum material purity and preventing oxidation: A retort furnace is the definitive choice due to its sealed, controlled atmosphere.

- If your process requires specific gas environments (like hydrogen or argon): The sealed nature and atmosphere control system of a retort furnace are non-negotiable.

- If your application is simple heating where air exposure is not a concern: A standard, non-retort atmospheric furnace is likely a more cost-effective and straightforward solution.

Understanding this core principle of environmental separation empowers you to select the right tool for any thermal processing challenge.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Heat materials in a sealed retort to prevent contamination and control atmosphere precisely. |

| Key Benefit | High-purity results by isolating material from heating elements and external air. |

| Atmosphere Control | Allows vacuum, inert, or reactive gas environments for versatile processes. |

| Ideal For | Applications requiring oxidation prevention, specific gas reactions, or low gas consumption. |

Upgrade your lab's thermal processing with KINTEK's advanced retort furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Ensure high-purity results and efficient atmosphere control—contact us today to discuss how our furnaces can enhance your research and production outcomes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.