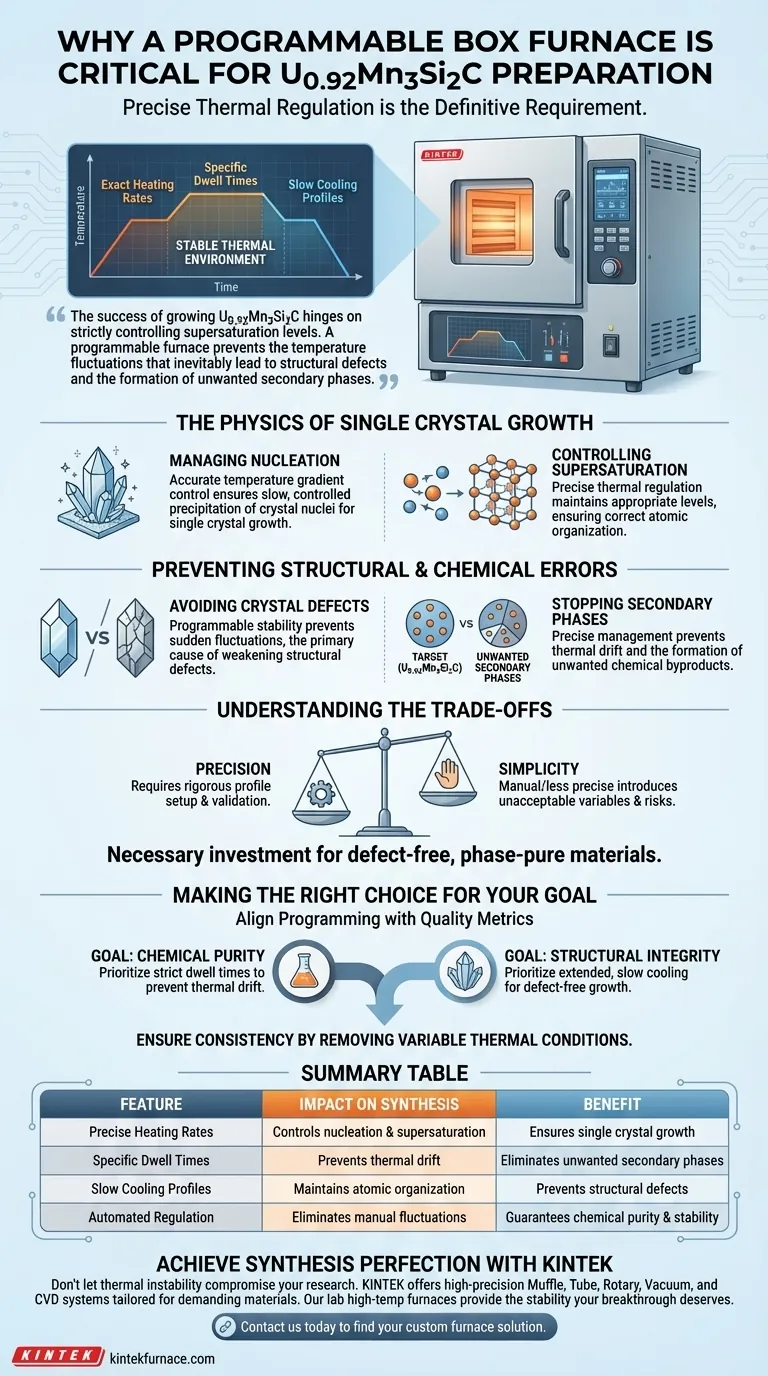

Precise thermal regulation is the definitive requirement. A programmable box furnace is critical for the preparation of U0.92Mn3Si2C because it enables the exact management of heating rates, specific dwell times, and slow cooling profiles. Without this automated precision, it is virtually impossible to maintain the stable thermal environment required for high-quality synthesis.

The success of growing U0.92Mn3Si2C hinges on strictly controlling supersaturation levels. A programmable furnace prevents the temperature fluctuations that inevitably lead to structural defects and the formation of unwanted secondary phases.

The Physics of Single Crystal Growth

Managing Nucleation

Accurate temperature gradient control is vital for this specific material. It ensures that crystal nuclei precipitate slowly rather than rapidly or chaotically. This controlled precipitation is the foundational step for achieving single crystal growth.

Controlling Supersaturation

The furnace allows you to maintain appropriate supersaturation levels throughout the process. By regulating the thermal environment precisely, the programmable system ensures the material organizes correctly at the atomic level, rather than freezing into a disordered state.

Preventing Structural and Chemical Errors

Avoiding Crystal Defects

Thermal stability is non-negotiable for structural integrity. The programmable nature of the furnace prevents sudden temperature fluctuations. These fluctuations are the primary cause of crystal defects, which weaken the material and alter its physical properties.

Stopping Secondary Phases

Inconsistent heating does more than just damage the crystal structure; it alters the chemistry. Precise thermal management prevents the formation of secondary phases. These are unwanted chemical byproducts that occur when the temperature drifts outside the optimal growth window.

Understanding the Trade-offs

Precision vs. Simplicity

The use of a programmable furnace introduces a requirement for rigorous profile setup and validation. However, the trade-off is clear: attempting this synthesis with manual or less precise equipment introduces unacceptable variables. The risk of defects and phase impurities makes the complexity of programmable control a necessary investment for this specific material.

Making the Right Choice for Your Goal

To maximize the quality of your U0.92Mn3Si2C preparation, align your furnace programming with your specific quality metrics:

- If your primary focus is Chemical Purity: Ensure your profile prioritizes strict dwell times to prevent the thermal drift that creates secondary phases.

- If your primary focus is Structural Integrity: Prioritize extended, slow cooling profiles to maintain the supersaturation levels needed for defect-free single crystal growth.

By removing variable thermal conditions from the equation, you ensure both the structural and chemical consistency of the final product.

Summary Table:

| Feature | Impact on U0.92Mn3Si2C Synthesis | Benefit |

|---|---|---|

| Precise Heating Rates | Controls nucleation & supersaturation | Ensures single crystal growth |

| Specific Dwell Times | Prevents thermal drift | Eliminates unwanted secondary phases |

| Slow Cooling Profiles | Maintains atomic organization | Prevents structural defects |

| Automated Regulation | Eliminates manual fluctuations | Guarantees chemical purity & stability |

Achieve Synthesis Perfection with KINTEK

Don't let thermal instability compromise your high-purity research. Backed by expert R&D and world-class manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the most demanding materials like U0.92Mn3Si2C.

Whether you require exact supersaturation control or customizable cooling profiles, our lab high-temp furnaces provide the stability your breakthrough deserves. Contact us today to find your custom furnace solution and elevate your material integrity.

Visual Guide

References

- Hope A. Long, Vladislav V. Klepov. Synthesis of U<sub>0.92</sub>Mn<sub>3</sub>Si<sub>2</sub>C Using Organic Carbon Source. DOI: 10.1002/zaac.202500047

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the functions of sample ports and flame curtains in atmospheric furnaces? Ensure Control and Safety in Heat Treatment

- How does a high-temperature furnace regulate pore structures in Hanji-derived carbon? Optimize Your Carbon Activation

- How is the room air displaced in a furnace to operate in different atmospheres? Master Purging for Precise Material Control

- What is the primary function of a controlled atmosphere device in powder metallurgy? Ensure Pure Sintering Results

- What industries commonly use retort furnaces? Essential for Controlled High-Temperature Processing

- How are retort furnaces utilized in laboratory settings? Essential for Controlled Atmosphere Thermal Processes

- How does an argon protection system contribute to composition control of CrMnFeCoNi? Ensure High-Entropy Alloy Purity

- Why is a controlled atmosphere sintering furnace required for porous metal? Ensure Strength and Prevent Oxidation