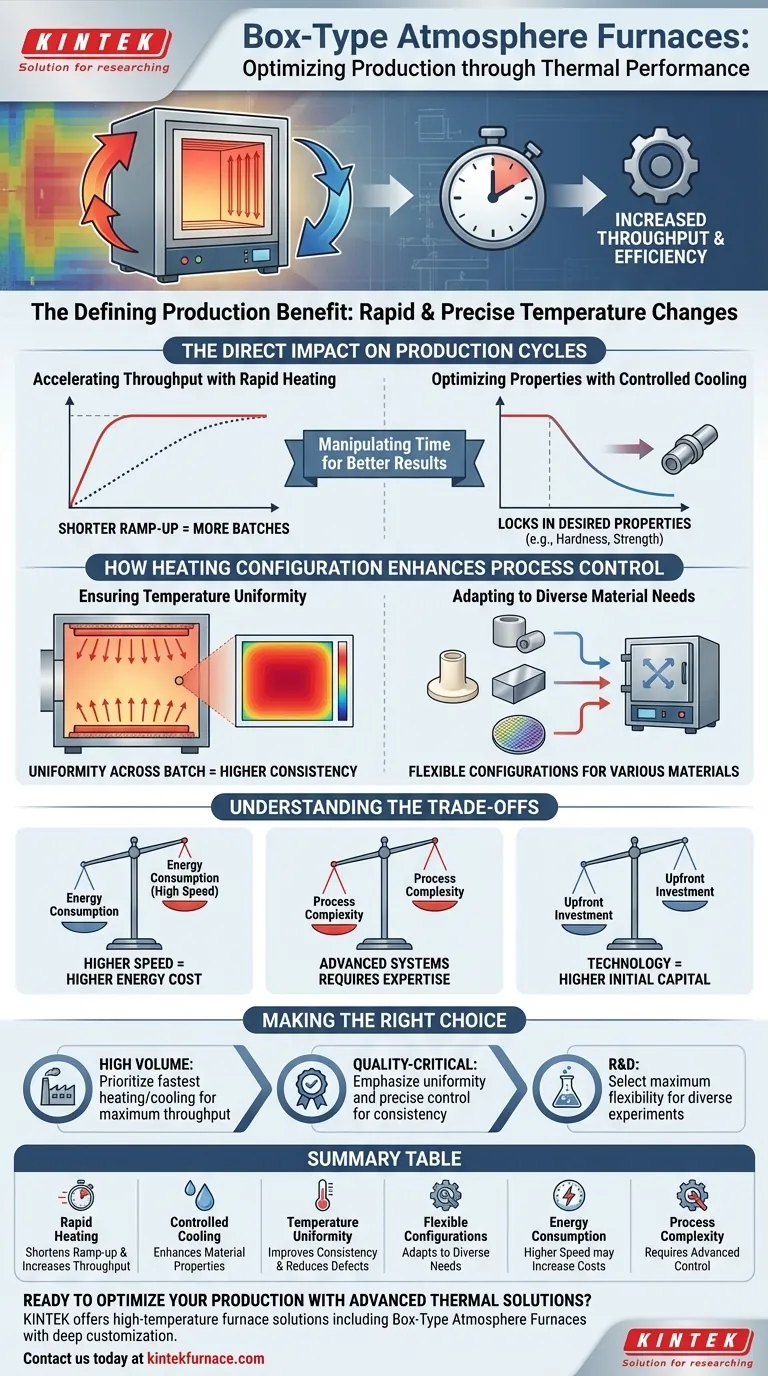

The defining production benefit of a box-type atmosphere furnace is its ability to execute rapid and precise temperature changes. Advanced heating and cooling technologies directly shorten heat treatment cycles, which increases throughput and improves overall operational efficiency. This capability allows for more batches to be processed in the same amount of time, providing a direct boost to productivity.

The performance of a box-type atmosphere furnace is not just about changing temperature quickly. It is about achieving precise, repeatable thermal profiles that shorten production cycles, enhance material properties, and provide the flexibility to process a wider range of materials.

The Direct Impact on Production Cycles

The core value proposition of a high-performance furnace is its ability to manipulate time. By accelerating heating and cooling, it fundamentally alters production timelines and material outcomes.

Accelerating Throughput with Rapid Heating

Advanced heating elements and control systems allow the furnace to reach its target temperature significantly faster than older models.

This reduction in "ramp-up" time means each processing cycle starts sooner, minimizing equipment idle time. Over the course of a day or week, this shaved time accumulates, allowing for additional production runs.

Optimizing Properties with Controlled Cooling

The cooling phase is as critical as the heating phase for many materials. The ability to cool down rapidly and in a controlled manner is essential for "locking in" desired metallurgical or crystalline structures.

For example, in metal processing, rapid cooling (quenching) is necessary to achieve specific hardness and strength characteristics. A furnace with poor cooling control cannot reliably produce materials with these properties.

How Heating Configuration Enhances Process Control

Beyond speed, the method of applying heat is crucial for quality and versatility. Modern furnaces offer configurations that ensure uniformity and adaptability.

Ensuring Temperature Uniformity

Supporting multiple heating configurations, such as top and bottom or three-sided heating, is key to eliminating hot and cold spots within the furnace chamber.

This temperature uniformity ensures that every part in a batch—whether at the center or the edge—receives the exact same thermal treatment. This directly translates to higher product consistency, reduced rejection rates, and improved yields, especially in sensitive applications like semiconductor manufacturing.

Adapting to Diverse Material Needs

The flexibility to adjust the heating configuration allows a single furnace to be used for a wide array of applications.

Different materials have unique thermal requirements. Ceramics may require a slow, even soak, while certain metal alloys need a rapid ramp-up. This adaptability makes the furnace a versatile asset in environments from materials science labs to multi-product manufacturing floors.

Understanding the Trade-offs

While the benefits are significant, it is important to consider the associated trade-offs of high-performance thermal systems.

Energy Consumption vs. Speed

Rapid heating and cooling cycles are, by nature, energy-intensive. While modern insulation and power controls improve efficiency, achieving maximum speed often comes at the cost of higher energy consumption.

Process Complexity

Furnaces with advanced thermal capabilities require more sophisticated control systems. This may involve a steeper learning curve for operators and more complex programming to define the precise heating and cooling profiles required for a given process.

Upfront Investment

The technology that enables rapid, uniform, and flexible heating—such as advanced elements, power supplies, and control software—represents a higher initial capital investment compared to basic furnace models.

Making the Right Choice for Your Application

Selecting a furnace requires aligning its thermal performance with your specific production goals.

- If your primary focus is high-volume manufacturing: Prioritize furnaces with the fastest possible heating and cooling rates to maximize throughput and shorten cycle times.

- If your primary focus is quality-critical production (e.g., electronics, aerospace): Emphasize systems with proven temperature uniformity and precise process control to ensure consistency and minimize defects.

- If your primary focus is research and development: Select a furnace with maximum flexibility in heating configurations and programming to accommodate a wide range of experimental materials and processes.

Ultimately, leveraging the advanced thermal performance of these furnaces transforms them from a simple heat source into a strategic tool for process optimization.

Summary Table:

| Performance Aspect | Key Benefit |

|---|---|

| Rapid Heating | Shortens ramp-up time, increases throughput |

| Controlled Cooling | Enhances material properties like hardness |

| Temperature Uniformity | Improves product consistency and reduces defects |

| Flexible Configurations | Adapts to diverse materials and processes |

| Energy Consumption | Higher speed may increase operational costs |

| Process Complexity | Requires advanced control systems and operator training |

Ready to optimize your production with advanced thermal solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions. Our product line, including Box-Type Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how our furnaces can enhance your efficiency and quality!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance