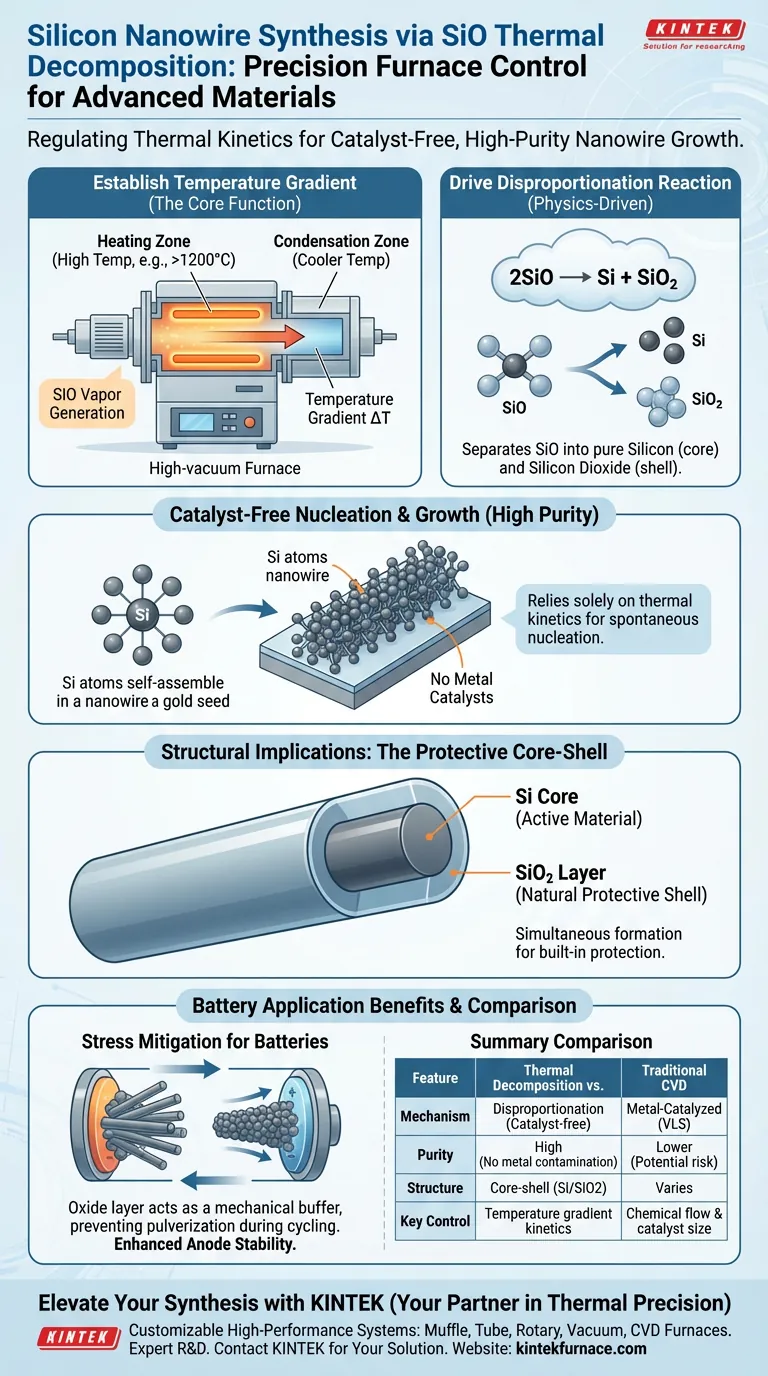

A high-vacuum or atmosphere furnace serves as a precision tool for regulating the thermal kinetics required to convert silicon monoxide (SiO) into silicon nanowires. By establishing and strictly controlling a temperature gradient between a heating zone and a condensation zone, the furnace manipulates the natural disproportionation reaction of SiO to dictate the nucleation and growth of nanowires without requiring external metal catalysts.

By leveraging precise temperature differentials rather than chemical additives, this method produces high-purity nanowires with a naturally occurring protective oxide shell, making them structurally superior for high-stress applications like battery anodes.

The Mechanics of Thermal Decomposition

Establishing the Temperature Gradient

The core function of the furnace is to create two distinct thermal environments: a high-temperature heating zone and a cooler condensation zone.

The precise adjustment of the temperature difference between these zones is the primary control variable. This gradient dictates the rate at which silicon monoxide vapor moves and condenses.

Driving the Disproportionation Reaction

Within this controlled environment, the furnace facilitates the disproportionation of silicon monoxide.

This reaction ($2SiO \rightarrow Si + SiO_2$) separates the SiO into pure silicon and silicon dioxide. The furnace utilizes the kinetic differences inherent in this reaction to drive the specific formation of wire-like structures rather than bulk clusters.

Catalyst-Free Nucleation

Unlike traditional methods that require metal catalysts (like gold) to seed growth, this furnace-based approach relies solely on thermal kinetics.

The specific temperature gradient allows the silicon to nucleate and grow into nanowires spontaneously. This results in a purer structure free from metal contamination.

Structural Implications for Battery Applications

Formation of the Protective Layer

A critical structural outcome of this furnace process is the natural formation of a silicon dioxide (SiO2) layer.

Because the disproportionation reaction produces both Si and SiO2, the silicon forms the nanowire core while the oxide forms a shell. This happens simultaneously during the growth phase inside the furnace.

Mitigating Stress Accumulation

This composite structure is particularly valuable for energy storage applications.

During battery cycling, silicon expands and contracts significantly. The furnace-grown oxide layer acts as a mechanical buffer, helping to mitigate stress accumulation and preventing the pulverization of the anode material.

Understanding the Trade-offs

Sensitivity to Thermal Precision

The process relies entirely on "precisely adjusting" the temperature difference.

This means the system is highly sensitive to thermal fluctuations. Even minor deviations in the temperature gradient can alter the kinetics, potentially failing to trigger the correct nucleation or resulting in inconsistent wire diameters.

Process Control vs. Throughput

Achieving this level of atmospheric and thermal control generally requires batch processing in high-vacuum environments.

While this ensures high structural quality and purity, it typically presents a trade-off regarding production speed compared to less controlled, continuous-flow synthesis methods.

Making the Right Choice for Your Goal

To determine if this synthesis method aligns with your project requirements, consider your specific performance targets:

- If your primary focus is Material Purity: This method is ideal because it eliminates the risk of metal contamination by removing the need for catalysts.

- If your primary focus is Cycle Life (Batteries): The natural formation of the SiO2 protective layer provides the stress mitigation necessary for long-term anode stability.

This furnace technique represents a shift from chemical-driven synthesis to physics-driven synthesis, prioritizing structural integrity through thermal precision.

Summary Table:

| Feature | Thermal Decomposition Method (Furnace-Driven) | Traditional Chemical Vapor Deposition (CVD) |

|---|---|---|

| Mechanism | Disproportionation ($2SiO \rightarrow Si + SiO_2$) | Metal-Catalyzed Nucleation (VLS) |

| Purity | High (Catalyst-free) | Lower (Potential metal contamination) |

| Structure | Core-shell (Si core/SiO2 shell) | Varies based on precursor |

| Stress Resistance | Excellent (Built-in oxide buffer) | Requires secondary coating |

| Key Control | Temperature gradient kinetics | Chemical flow and catalyst size |

Elevate Your Advanced Material Synthesis with KINTEK

Precision thermal kinetics are the foundation of high-performance silicon nanowire production. At KINTEK, we understand that even a minor thermal deviation can compromise your material's structural integrity.

Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the exacting temperature gradients required for catalyst-free synthesis. Whether you are developing next-generation battery anodes or high-purity semiconductors, our lab high-temp furnaces are fully customizable to meet your unique research and production needs.

Ready to achieve superior thermal precision? Contact our technical specialists today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Xinyu Chen, Lin Zeng. Advancing high‐performance one‐dimensional Si/carbon anodes: Current status and challenges. DOI: 10.1002/cnl2.118

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a reactive furnace atmosphere benefit heat treatment? Enhance Surface Hardness and Wear Resistance

- Why is a strictly controlled argon (Ar) atmosphere required for Fe2O3@PDA pyrolysis? Ensure Superior Carbonization

- What is the endothermic gas in heat treatment? Master Carbon Control for Superior Steel Hardening

- What is an inert atmosphere furnace? Protect Materials from Oxidation and Contamination

- What are the advantages of an atmosphere protection box furnace? Achieve Scale-Free, High-Precision Metal Annealing

- Why is temperature and atmosphere monitoring critical in furnace operations? Ensure Safety and Quality in Heat Treatment

- How are retort furnaces utilized in laboratory settings? Essential for Controlled Atmosphere Thermal Processes

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening