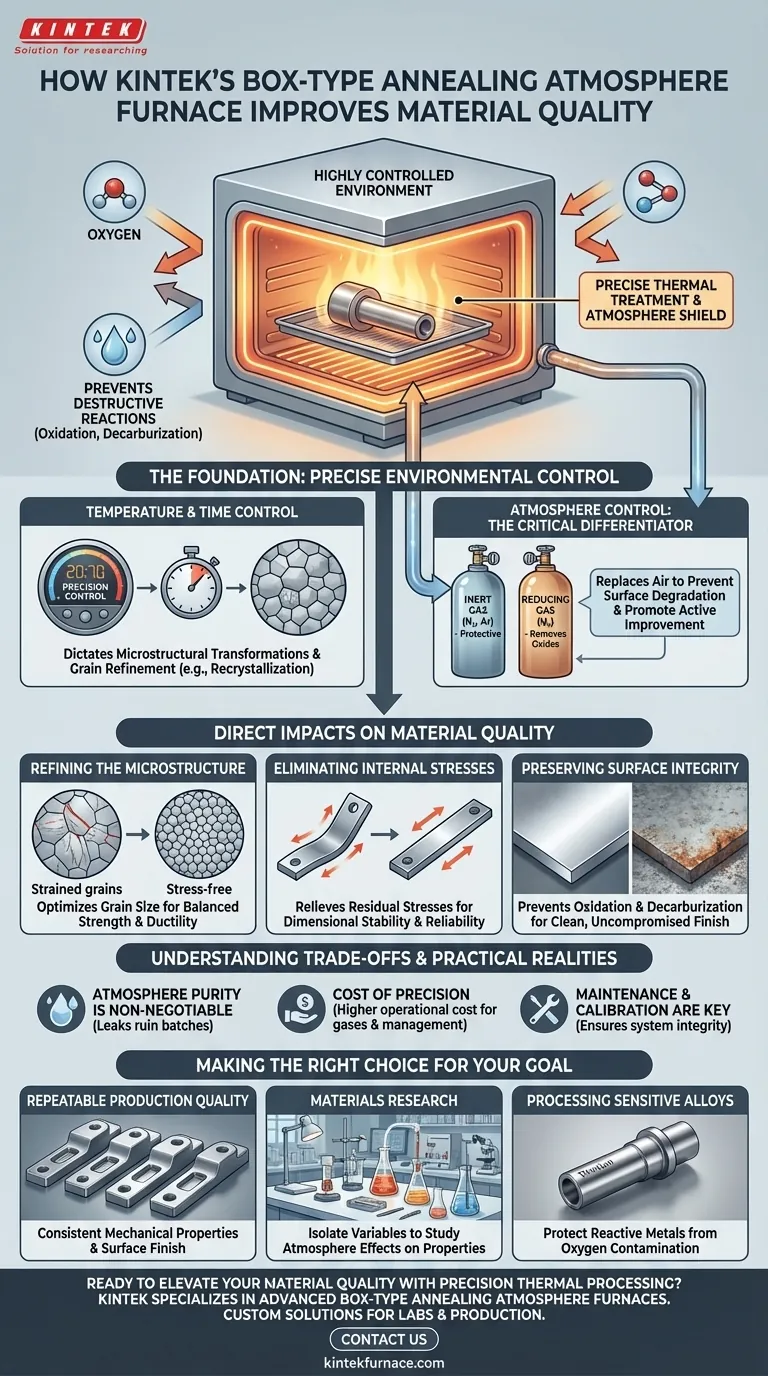

At its core, a box-type annealing atmosphere furnace improves material quality by creating a highly controlled environment that protects the material's surface while its internal structure is being refined. This precise control over temperature, time, and atmosphere allows for the targeted enhancement of mechanical properties, such as strength and ductility, which is impossible to achieve when heating in open air.

The furnace's primary value is not just in the heat it applies, but in the controlled atmosphere it maintains. This atmosphere acts as a shield, preventing destructive surface reactions like oxidation and allowing the thermal treatment to achieve its intended effect on the material's internal microstructure.

The Foundation: Precise Environmental Control

The furnace's ability to transform materials stems from its precise management of the three fundamental variables of thermal processing. The "atmosphere" component is what separates this technology from a standard oven.

Temperature and Time Control

The specific temperature and the duration it is held (soak time) directly govern metallurgical changes. Precise temperature control dictates which microstructural transformations occur, such as recrystallization or phase changes.

Time at temperature allows these transformations to complete. This combination is used to refine grain structure, dissolve precipitates, or relieve internal stresses locked in from previous manufacturing steps.

Atmosphere Control: The Critical Differentiator

Heating a metal in the presence of oxygen causes oxidation, forming a brittle, useless scale on the surface. For steels, it can also cause decarburization, where carbon leaches from the surface, making it soft and weak.

An atmosphere furnace prevents this by replacing the air with a specific gas mixture. A protective atmosphere, typically nitrogen or argon, is inert and prevents any reaction with the metal surface. A reducing atmosphere, often containing hydrogen, can actively remove any surface oxides that may have been present.

Direct Impacts on Material Quality

By mastering the environment, an atmosphere furnace delivers tangible and predictable improvements to the final component. These changes occur at both the microscopic structural level and the macroscopic performance level.

Refining the Microstructure

Nearly all of a metal's mechanical properties are dictated by its microstructure, particularly its grain size. Annealing in a controlled environment allows for processes like recrystallization, which replaces strained, deformed grains with new, stress-free ones.

This refines the grain structure, often leading to an optimal balance of strength and ductility. It is a fundamental tool for "resetting" a material after it has been hardened by processes like stamping or drawing.

Eliminating Internal Stresses

Manufacturing processes like welding, machining, or cold forming leave behind residual stresses within a material. These hidden stresses can cause warping over time or lead to premature failure under load.

A controlled annealing cycle provides the thermal energy needed for atoms to rearrange themselves into a lower-energy, stress-free state. This greatly improves the dimensional stability and reliability of the finished part.

Preserving Surface Integrity

The furnace's most visible benefit is a clean, bright, and uncompromised material surface. By preventing oxidation, the furnace eliminates the need for post-treatment cleaning operations like acid pickling or sandblasting, which add cost and can damage the part.

For components where surface hardness is critical, preventing decarburization ensures the material's full performance potential is realized.

Understanding the Trade-offs and Practical Realities

While powerful, this technology requires a clear understanding of its operational demands and limitations to be used effectively.

Atmosphere Purity is Non-Negotiable

The entire process relies on maintaining a pure, controlled atmosphere. Even a small leak in a door seal or a contaminated gas supply can introduce oxygen or moisture, ruining an entire batch of high-value components. This is why robust sealing structures and gas quality monitoring are critical features.

The Cost of Precision

Atmosphere furnaces are more complex and have a higher operational cost than simple air furnaces. The continuous consumption of high-purity gases (like argon or nitrogen) and the systems required to manage them represent a significant ongoing expense.

Maintenance and Calibration Are Key

The promise of "precise control" is only met if the system is properly maintained. This includes regularly calibrating the temperature control system, inspecting heating elements, and ensuring the atmosphere control system is leak-free and functioning correctly. Neglecting maintenance undermines the very purpose of the equipment.

Making the Right Choice for Your Goal

The decision to use an atmosphere furnace should be driven by the specific quality requirements of your material or component.

- If your primary focus is repeatable production quality: Use the furnace to eliminate surface defects like oxidation and ensure every part has consistent mechanical properties by relieving residual stresses.

- If your primary focus is materials research: Leverage the furnace's precise control to isolate variables and systematically study how temperature and different atmospheres affect a material's properties, like thermal stability or corrosion resistance.

- If your primary focus is processing sensitive alloys: Rely on the inert atmosphere to protect reactive materials like titanium or certain stainless steels from oxygen contamination, which can render them brittle and unusable.

Ultimately, mastering the use of a box-type atmosphere furnace is about moving from simply heating a material to truly engineering its final properties.

Summary Table:

| Key Improvement | Description |

|---|---|

| Microstructure Refinement | Achieves optimal grain size for balanced strength and ductility through recrystallization. |

| Stress Relief | Eliminates residual stresses from manufacturing, improving dimensional stability and reliability. |

| Surface Protection | Prevents oxidation and decarburization, preserving surface integrity and reducing post-treatment needs. |

| Controlled Atmosphere | Uses inert or reducing gases to shield materials, enabling precise thermal processing without surface damage. |

Ready to elevate your material quality with precision thermal processing? KINTEK specializes in advanced high-temperature furnace solutions, including Box-Type Annealing Atmosphere Furnaces, designed for diverse laboratory needs. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements—whether for repeatable production, materials research, or sensitive alloy handling. Contact us today to discuss how our expertise can enhance your processes and deliver reliable, high-performance results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments