In an atmosphere furnace, the sealing mechanism is not a secondary feature—it is the core component that makes the entire process possible. These mechanisms, typically high-temperature gaskets and seals, are critical because they create an airtight barrier that isolates the internal environment. This prevents reactive ambient air from contaminating the process, ensures the controlled atmosphere is maintained efficiently, and guarantees process repeatability and safety.

The integrity of any heat treatment process is directly proportional to the integrity of the furnace's seal. It is the single most critical barrier separating a precisely engineered internal atmosphere from the reactive and unpredictable outside world.

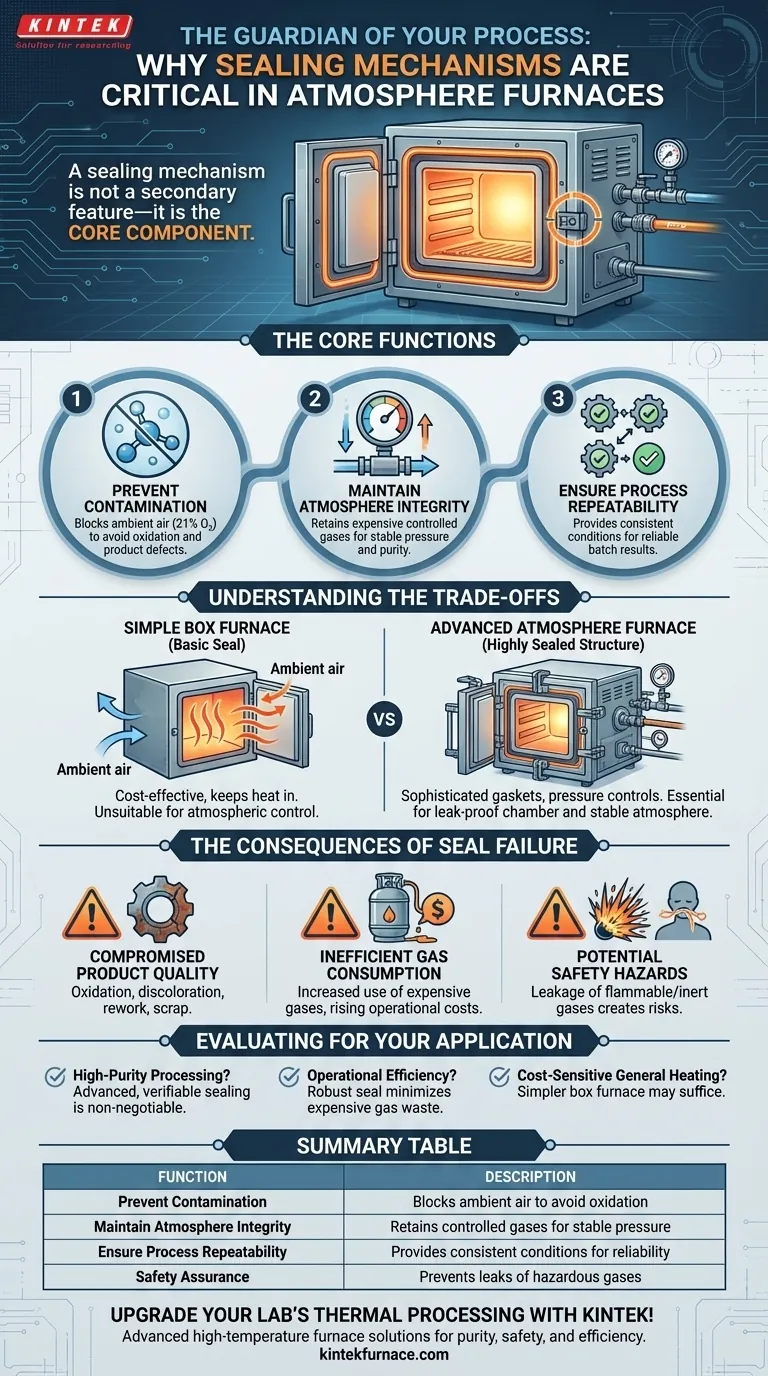

The Core Functions of a Furnace Seal

A sealing mechanism performs two fundamental jobs simultaneously: it keeps the bad air out and the good gas in. The quality of the seal directly dictates the quality of the final product.

Preventing Atmospheric Contamination

The primary purpose of an atmosphere furnace is to heat parts in a specific, non-reactive environment. Ambient air, with its ~21% oxygen and variable moisture, is a potent contaminant.

An effective seal prevents this outside air from entering the furnace chamber. Even a minor leak can introduce oxygen, leading to oxidation, discoloration, and a failure to meet material specifications, especially in sensitive processes involving materials like molten metal.

Maintaining Atmospheric Integrity

These furnaces operate by filling the chamber with a specific gas, such as nitrogen, argon, or hydrogen. This controlled atmosphere must be maintained at a consistent pressure and purity.

A robust seal ensures this expensive gas is not lost to the outside environment. It maintains the positive pressure required to keep the atmosphere stable, preventing inefficiencies and ensuring the chemical reactions—or lack thereof—proceed exactly as designed.

Ensuring Process Repeatability

For industrial applications, consistency is key. A product treated today must have the same properties as one treated next month.

Because the seal guarantees a stable, predictable internal environment, it is the foundation of a repeatable process. Without a perfect seal, atmospheric conditions would fluctuate, leading to inconsistent and unreliable results from one batch to the next.

Understanding the Trade-offs: Seal Complexity and Cost

The need for atmospheric control is the primary distinction between a simple furnace and a true atmosphere furnace, a difference directly reflected in the complexity and cost of their sealing designs.

The Standard Box Furnace

A simple box furnace, used for general heating in ambient air, has a basic sealing design on its door. Its goal is merely to keep heat in, not to control the atmosphere.

This design is cost-effective and simple to manufacture and maintain. However, it is completely unsuitable for any process that requires protection from oxidation.

The Advanced Atmosphere Furnace

An atmosphere furnace requires a highly sealed structure. This involves sophisticated door clamps, high-temperature gaskets (like silicone or graphite), and integrated gas inlet and outlet systems with pressure controls.

This complexity is not optional; it is essential to creating a leak-proof chamber capable of maintaining a stable, high-purity atmosphere. This results in a more complex manufacturing process and a higher initial investment.

The Consequences of Seal Failure

A compromised seal is not a minor issue; it represents a fundamental failure of the furnace's primary function and carries significant consequences.

Compromised Product Quality

The most immediate result of a bad seal is product failure. Parts may emerge oxidized, discolored, or with altered mechanical properties. This leads to costly rework, scrap, and customer dissatisfaction.

Inefficient Gas Consumption

If the furnace is constantly leaking the controlled atmosphere, the system must pump in more gas to maintain the required pressure. This dramatically increases the consumption of expensive gases like argon or hydrogen, leading to a significant rise in operational costs.

Potential Safety Hazards

Seal failure can also create serious safety risks. The leakage of flammable process gases, such as hydrogen, can create an explosion hazard in the surrounding workspace. Similarly, the leakage of inert gases like nitrogen can displace oxygen, creating a suffocation risk for personnel.

Evaluating Sealing for Your Application

Choosing the right furnace means matching the sealing integrity to your process requirements. The seal is not a feature to be compromised on; it is an investment in quality, efficiency, and safety.

- If your primary focus is high-purity processing (e.g., brazing, bright annealing): A furnace with an advanced, verifiable sealing mechanism is non-negotiable to prevent product defects.

- If your primary focus is operational efficiency: Invest in a furnace with a robust, well-engineered seal to minimize expensive gas waste and reduce long-term operational costs.

- If your primary focus is cost-sensitive general heating without atmospheric control: A simpler box furnace with a basic door seal will be sufficient and more economical for your needs.

Ultimately, the seal is the guardian of your process, directly determining the quality, safety, and efficiency of your thermal operations.

Summary Table:

| Function | Description |

|---|---|

| Prevent Contamination | Blocks ambient air to avoid oxidation and product defects |

| Maintain Atmosphere Integrity | Retains controlled gases for stable pressure and purity |

| Ensure Process Repeatability | Provides consistent conditions for reliable batch results |

| Safety Assurance | Prevents leaks of hazardous gases to mitigate explosion and suffocation risks |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Ensure purity, safety, and efficiency in your processes—contact us today for a tailored solution!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage