At its core, operating an atmosphere furnace safely requires managing both the extreme heat and the reactive, often flammable, gas environment inside. Key safety considerations include using a sealed, airtight furnace design, maintaining positive internal pressure to prevent air intrusion, continuous monitoring of the atmosphere and temperature, and adhering to strict operational procedures for gas handling.

The fundamental shift from a standard furnace to an atmosphere furnace is recognizing that the primary hazard is no longer just heat, but the potential for an explosive or toxic gas mixture. Therefore, controlling the integrity and composition of the internal atmosphere is the most critical safety objective.

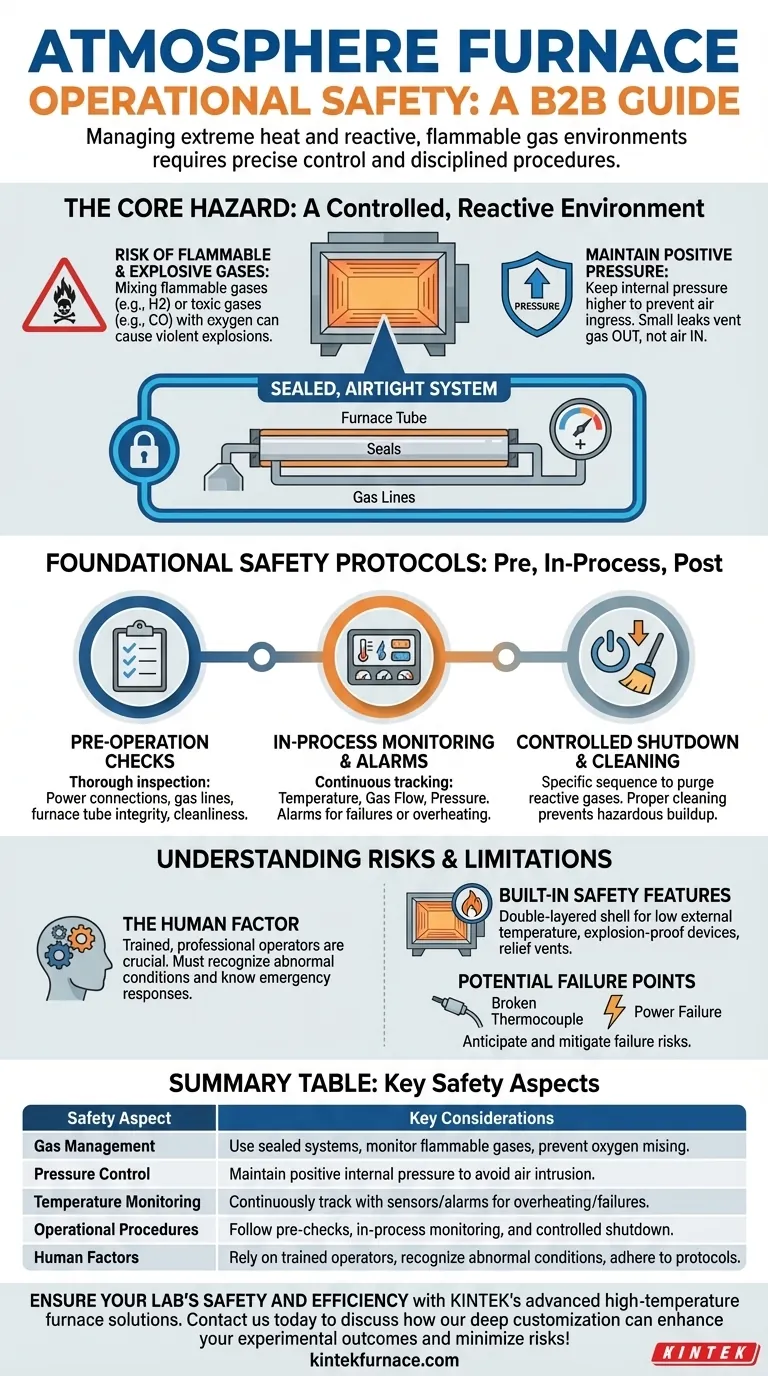

The Core Hazard: A Controlled, Reactive Environment

Unlike a standard box furnace that simply heats a part in ambient air, an atmosphere furnace replaces that air with a specific, controlled gas. This introduces a significant new layer of risk that must be managed with precision.

The Risk of Flammable and Explosive Gases

Many processes require atmospheres containing flammable gases like hydrogen or gases that can be toxic, such as carbon monoxide. The primary danger is the unintended mixing of these gases with oxygen from the air.

This combination, when ignited by the furnace's high temperatures, can lead to a violent explosion. This is why atmosphere furnaces demand a much higher safety threshold than their simpler counterparts.

Maintaining Positive Pressure

The single most important principle for preventing an explosive mixture is maintaining positive pressure inside the furnace chamber.

This means the gas pressure inside the furnace is slightly higher than the atmospheric pressure outside. This ensures that if any small leak exists, the controlled atmosphere gas will leak out rather than air leaking in, preventing oxygen from entering the hot zone.

The Importance of a Sealed System

To maintain positive pressure and contain the controlled atmosphere, the furnace must be designed as a sealed, airtight system.

Any damage to furnace tubes, seals, or gas lines compromises this integrity. It can lead to dangerous gas leaking into the workspace or catastrophic air ingress into the furnace chamber.

Foundational Safety Protocols: Before, During, and After

A safe operation is not a single action but a disciplined process. Procedures must be followed meticulously before, during, and after every heating cycle.

Pre-Operation System Checks

Before introducing heat or gas, a thorough inspection is mandatory. This includes checking for secure power connections, verifying the integrity of gas lines, and ensuring the furnace tube is undamaged and clean. Any residue from previous runs could react unpredictably with the new atmosphere.

In-Process Monitoring and Alarms

Continuous monitoring is non-negotiable. Modern furnaces are equipped with sensors and alarms to track critical parameters.

Operators must constantly monitor temperature, gas flow rates, and pressure. Alarms for power failures, overheating, underheating, or thermocouple breaks are essential safety features that provide an early warning of a developing problem.

Controlled Shutdown and Post-Use Cleaning

Shutting down the furnace requires a specific sequence, as defined by the manufacturer, to safely purge the reactive gases and cool the system. After the cycle, proper cleaning is essential to prevent the buildup of hazardous materials that could compromise future runs.

Understanding the Inherent Risks and Limitations

Even with perfect procedure, it's vital to understand the equipment's inherent risks and the critical role of the operator. True safety comes from respecting these limitations.

The Human Factor: The Need for Professional Operators

Atmosphere furnaces are not general-purpose equipment. They must be operated by trained, professional personnel who understand the chemical and physical principles at play. An operator must be able to recognize the signs of an abnormal condition and know the correct emergency response.

Built-in Safety Features

High-quality atmosphere furnaces incorporate passive and active safety features. A double-layered shell and high-grade insulation, for example, keep the external surface temperature low, protecting operators from burns. Explosion-proof devices or designated relief vents may also be included to manage a worst-case scenario.

Potential Failure Points

Operators must be aware of potential points of failure, such as a broken thermocouple providing a false temperature reading or a power failure shutting down gas flow controllers. Understanding these possibilities is key to anticipating and mitigating risk.

Implementing a Robust Safety Culture

Ultimately, safety depends on a combination of reliable equipment, disciplined procedures, and a well-trained team.

- If your primary focus is hands-on operation: Prioritize procedural discipline by diligently performing all pre-operation checks, continuously monitoring the system during a run, and never deviating from established shutdown protocols.

- If your primary focus is lab or facility management: Ensure operators receive comprehensive and recurring training, implement a strict preventative maintenance schedule, and invest only in equipment with certified, redundant safety systems.

Safe operation is the absolute prerequisite for achieving the high-quality, repeatable results that atmosphere furnaces make possible.

Summary Table:

| Safety Aspect | Key Considerations |

|---|---|

| Gas Management | Use sealed systems, monitor flammable gases like hydrogen, prevent oxygen mixing |

| Pressure Control | Maintain positive internal pressure to avoid air intrusion and explosions |

| Temperature Monitoring | Continuously track with sensors and alarms for overheating or failures |

| Operational Procedures | Follow pre-checks, in-process monitoring, and controlled shutdown sequences |

| Human Factors | Rely on trained operators, recognize abnormal conditions, and adhere to safety protocols |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability guarantees precise, safe operations for diverse laboratories. Contact us today to discuss how our expertise can enhance your experimental outcomes and minimize risks!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality