At their core, atmosphere furnaces are indispensable tools across a wide range of high-technology and traditional industries. They are most commonly used in metallurgy, electronics, ceramics, and automotive manufacturing, but their application extends to aerospace, materials science research, and the chemical industry for any process requiring precise high-temperature treatment without unwanted chemical reactions like oxidation.

The critical function of an atmosphere furnace is not just to generate heat, but to meticulously control the chemical environment around a material. This control prevents oxidation and other reactions, enabling the creation of materials and components with specific, high-performance properties that would be impossible to achieve in open air.

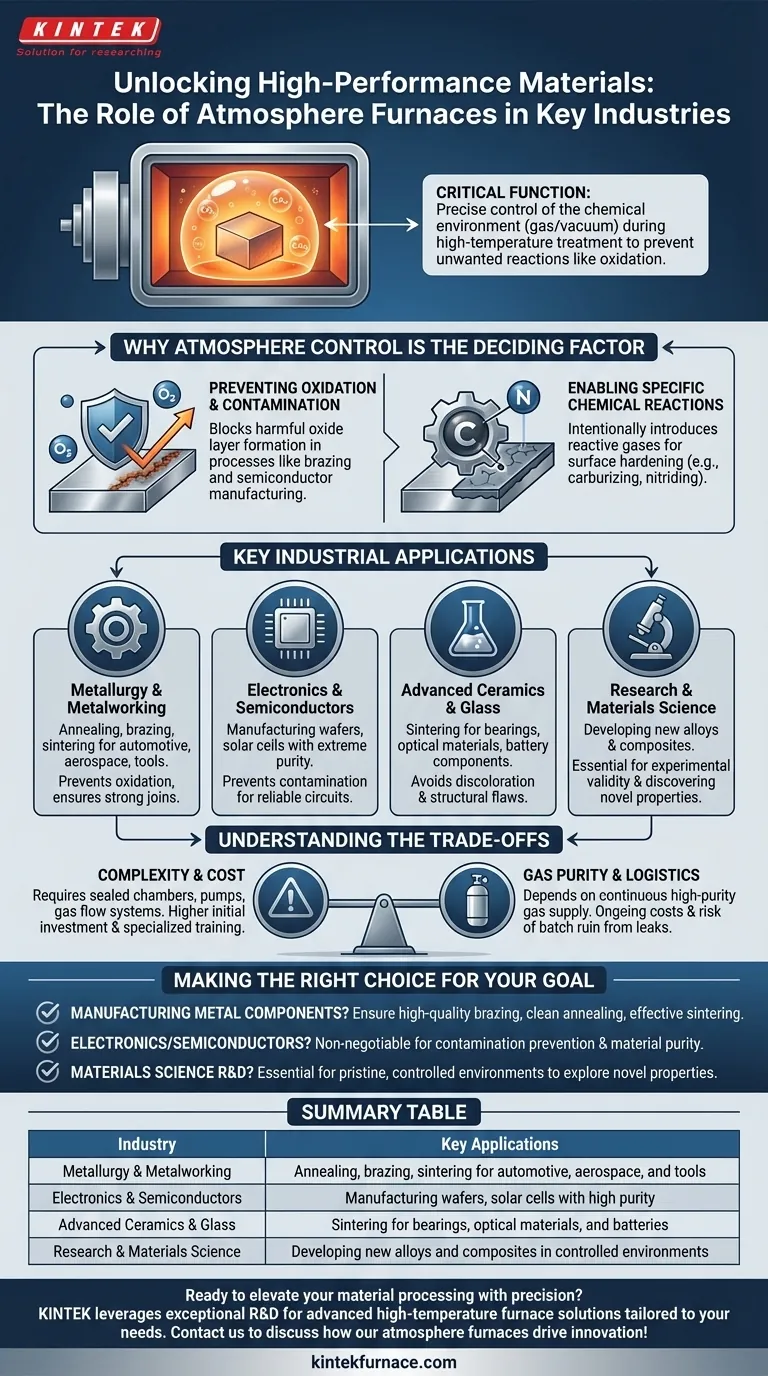

Why Atmosphere Control is the Deciding Factor

The defining feature of an atmosphere furnace is its ability to replace the ambient air (which is reactive, primarily due to oxygen) with a specific gas or a vacuum. This capability is not a minor detail; it is the fundamental reason these furnaces are chosen.

Preventing Oxidation and Contamination

At high temperatures, most materials—especially metals—react readily with oxygen in the air. This process, oxidation, forms a layer of oxide on the material's surface.

This oxide layer can be detrimental, preventing proper joining in processes like brazing, altering electrical properties in semiconductors, or compromising the structural integrity of an alloy.

Enabling Specific Chemical Reactions

In some advanced applications, the furnace atmosphere is not inert but reactive. A specific gas is introduced to intentionally cause a chemical reaction on the material's surface.

Processes like carburizing (introducing carbon to harden steel) or nitriding (introducing nitrogen for surface hardness) rely entirely on this principle of a controlled, reactive atmosphere.

Key Industrial Applications

The need for a controlled atmosphere drives the adoption of these furnaces across several critical sectors. Each industry leverages this technology to solve specific material challenges.

Metallurgy and Metalworking

This is the most traditional and widespread application. Industries from aerospace and automotive to tool manufacturing depend on atmosphere furnaces.

Key processes include annealing (to soften metal and improve ductility), brazing (to join parts without melting them), and sintering (to fuse metal powders into a solid mass). For example, brazing aluminum automotive parts requires a controlled atmosphere to prevent a tough, non-wettable oxide layer from forming.

Electronics and Semiconductors

In the electronics and semiconductor industry, purity is paramount. Even microscopic levels of oxidation or contamination can ruin a component.

Atmosphere furnaces are used for manufacturing semiconductor wafers, solar cells, and other electronic components. They provide the ultra-clean environment needed to create precise, reliable circuits and materials.

Advanced Ceramics and Glass

Technical ceramics and specialty glasses require precise firing cycles to achieve their desired density, strength, and optical properties.

Using a controlled atmosphere during sintering prevents unwanted reactions that could cause discoloration or structural flaws. This is critical for producing everything from ceramic bearings to advanced optical materials and components for the battery industry.

Research and Materials Science

For academic institutions and corporate R&D labs, an atmosphere furnace is an essential experimental tool.

It allows researchers to develop new alloys, composites, and materials under perfectly controlled and repeatable conditions. This is fundamental to discovering materials with novel properties for future applications.

Understanding the Trade-offs

While powerful, atmosphere furnaces introduce complexities and costs that must be managed. They are not a simple "plug-and-play" solution.

Equipment and Operational Complexity

An atmosphere furnace is a more complex system than a standard air furnace. It requires sealed chambers, vacuum pumps, and precise gas flow control systems.

This increases the initial investment and requires operators with specialized training to manage gas safety, prevent leaks, and ensure process integrity.

Gas Purity and Cost

The effectiveness of the process depends entirely on the purity of the atmosphere. This often requires a continuous supply of high-purity inert gases like argon or nitrogen, or reactive gases like hydrogen.

The ongoing cost of these gases, along with the logistics of their storage and handling, is a significant operational consideration. A small leak in the furnace can compromise the atmosphere, ruin an entire batch, and waste expensive gas.

Making the Right Choice for Your Goal

The decision to use an atmosphere furnace should be driven by the specific material requirements of your final product.

- If your primary focus is manufacturing metal components: You need an atmosphere furnace to ensure high-quality brazing, clean annealing, and effective sintering without compromising material strength.

- If your primary focus is electronics or semiconductors: A controlled atmosphere is non-negotiable to prevent contamination and achieve the required electrical and material purity.

- If your primary focus is materials science or R&D: The furnace is your primary tool for ensuring experimental validity and exploring the properties of novel materials in a pristine environment.

Ultimately, an atmosphere furnace is chosen when the chemical environment is as critical to the outcome as the temperature itself.

Summary Table:

| Industry | Key Applications |

|---|---|

| Metallurgy & Metalworking | Annealing, brazing, sintering for automotive, aerospace, and tools |

| Electronics & Semiconductors | Manufacturing wafers, solar cells with high purity |

| Advanced Ceramics & Glass | Sintering for bearings, optical materials, and batteries |

| Research & Materials Science | Developing new alloys and composites in controlled environments |

Ready to elevate your material processing with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like metallurgy, electronics, and ceramics. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our atmosphere furnaces can prevent oxidation, ensure purity, and drive innovation in your lab or production line!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage