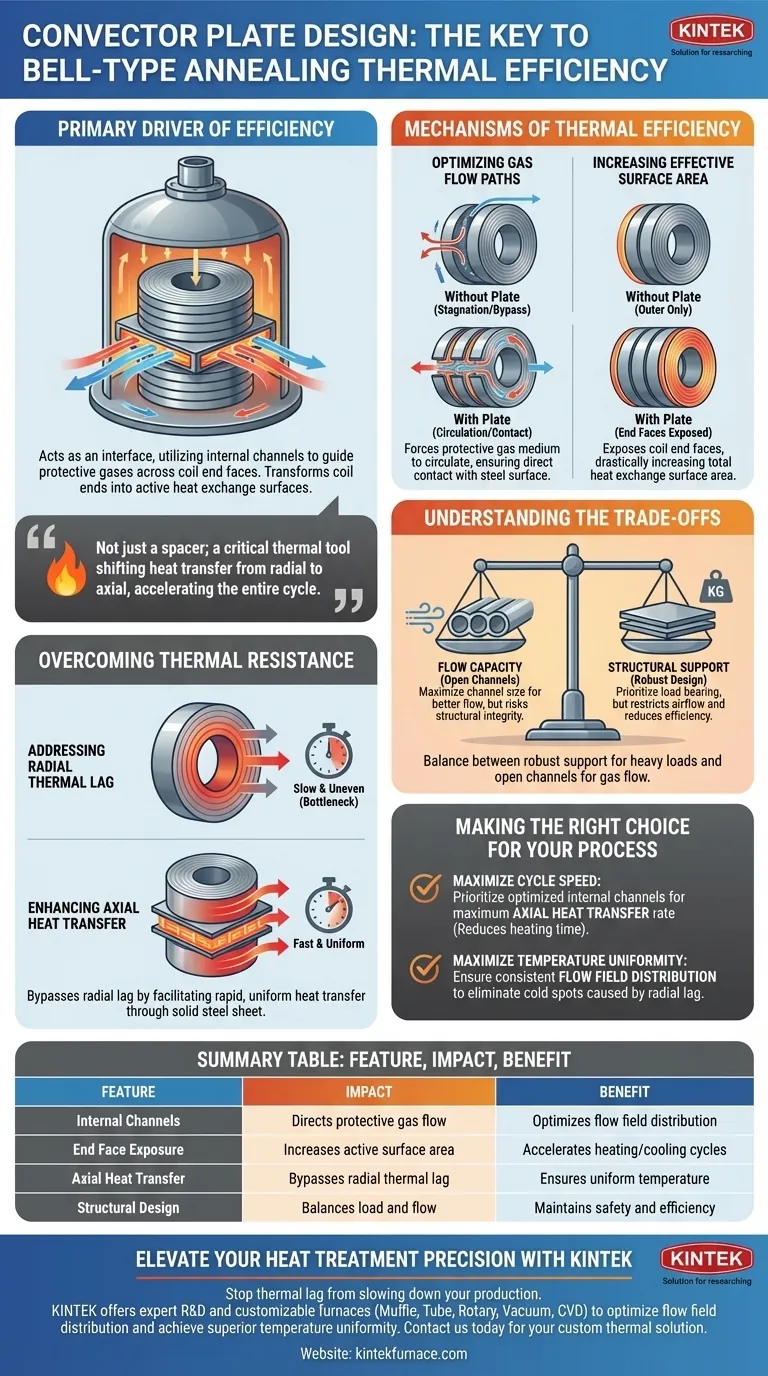

The design of a convector plate is the primary driver of airflow management and thermal efficiency within a bell-type annealing furnace. By acting as an interface between stacked steel coils, these plates utilize internal channels to guide protective gases directly across the coil end faces. This mechanism transforms the coil ends into active heat exchange surfaces, significantly optimizing the flow field distribution throughout the stack.

The convector plate is not merely a structural spacer; it is a critical thermal tool that overcomes the natural insulating properties of steel coils. By shifting the heat transfer mechanism from radial to axial, it mitigates thermal lag and accelerates the entire annealing cycle.

Mechanisms of Thermal Efficiency

Optimizing Gas Flow Paths

A standard steel coil acts as a barrier to airflow. A well-designed convector plate uses internal channels to create a specific path for protective gases.

Rather than allowing the gas to stagnate or bypass the material, the plate forces the medium to circulate between the coils. This ensures that the heating or cooling medium makes direct contact with the steel's surface.

Increasing Effective Surface Area

Heat transfer is a function of surface area. Without convector plates, only the outer circumference of the coil is exposed to the convective flow.

By spacing the coils apart and directing flow effectively, the plate exposes the end faces of the steel coils. This drastically increases the total surface area available for heat exchange.

Overcoming Thermal Resistance

Addressing Radial Thermal Lag

Steel coils have distinct thermal properties based on their orientation. Heat travels slowly through the layers of the coil (radially), creating a phenomenon known as radial thermal conductivity lag.

This "lag" usually acts as the bottleneck in the annealing process. Relying solely on radial heating results in uneven temperatures and longer cycle times.

Enhancing Axial Heat Transfer

The convector plate solves the radial lag issue by facilitating axial heat transfer.

By directing hot gases to the coil ends, heat moves through the solid sheet of steel rather than jumping across air gaps between layers. This axial rate is significantly faster and more uniform than radial conduction.

Understanding the Trade-offs

Flow Capacity vs. Structural Support

The design of a convector plate represents a balance between two opposing requirements.

First, it must be robust enough to act as a support structure for heavy stacks of steel coils. Second, it must be "open" enough to accommodate large internal channels for gas flow.

Prioritizing support too heavily restricts airflow and reduces thermal efficiency. Conversely, maximizing channel size to improve flow can compromise the plate's ability to bear weight safely.

Making the Right Choice for Your Process

To maximize the efficiency of your bell-type annealing furnace, the design of the convector plate must align with your specific thermal goals.

- If your primary focus is cycle speed: Prioritize designs with optimized internal channels that maximize the axial heat transfer rate to reduce heating time.

- If your primary focus is temperature uniformity: Ensure the plate design creates a consistent flow field distribution to eliminate cold spots caused by radial lag.

The effectiveness of your annealing process depends less on the furnace power and more on how effectively your convector plates guide the energy to where it is needed most.

Summary Table:

| Feature | Impact on Thermal Efficiency | Benefit for Annealing Process |

|---|---|---|

| Internal Channels | Directs protective gas flow between coils | Optimizes flow field distribution |

| End Face Exposure | Increases active heat exchange surface area | Accelerates heating and cooling cycles |

| Axial Heat Transfer | Bypasses radial thermal conductivity lag | Ensures uniform temperature distribution |

| Structural Design | Balances load support with flow capacity | Maintains safety without sacrificing efficiency |

Elevate Your Heat Treatment Precision with KINTEK

Is thermal lag slowing down your production? At KINTEK, we understand that the right furnace component is the difference between a bottleneck and a breakthrough. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized high-temperature lab furnaces—all fully customizable to meet your unique metallurgical needs.

Our team of specialists is ready to help you optimize your flow field distribution and achieve superior temperature uniformity. Contact us today to discuss your custom thermal solution and see how KINTEK can enhance your lab’s efficiency and performance.

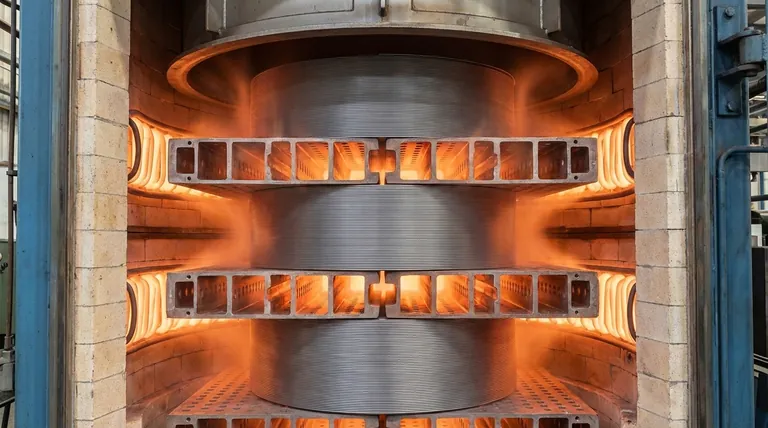

Visual Guide

References

- Yang Xiao-jing, Yu-Ren Li. Study of heat transfer model and buried thermocouple test of bell-type annealing furnace based on thermal equilibrium. DOI: 10.1038/s41598-025-97422-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a lamp furnace integrated with a tensile testing machine function? Expert High-Temp Shear Strength Analysis

- What is the primary purpose of using a constant temperature drying oven in sugarcane bagasse pretreatment? Find Out Why

- How do atmosphere furnaces contribute to improved material properties? Unlock Superior Strength and Finish

- What provides inert atmosphere for high-temperature metallurgical process? Prevent Oxidation with Argon & More

- What is inert atmosphere heat treating? Prevent Oxidation for Superior Material Quality

- How does a thermal oxidation furnace facilitate the phase transformation of metallic vanadium? Learn V2O5 Optimization

- What role does an industrial oven play in the pre-treatment of Licuri bark? Optimize Activated Carbon Production

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments