In short, inert atmosphere heat treating is a specialized process where materials are heated in a sealed environment that has been purged of oxygen. By replacing the air with an inert gas like nitrogen, it protects the material from oxidation, scaling, and other detrimental chemical reactions that would normally occur at high temperatures.

The fundamental purpose of inert atmosphere heat treating is not just to heat a material, but to do so without altering its surface or chemical composition. It is a protective measure that ensures the final product meets its precise engineering specifications from the inside out.

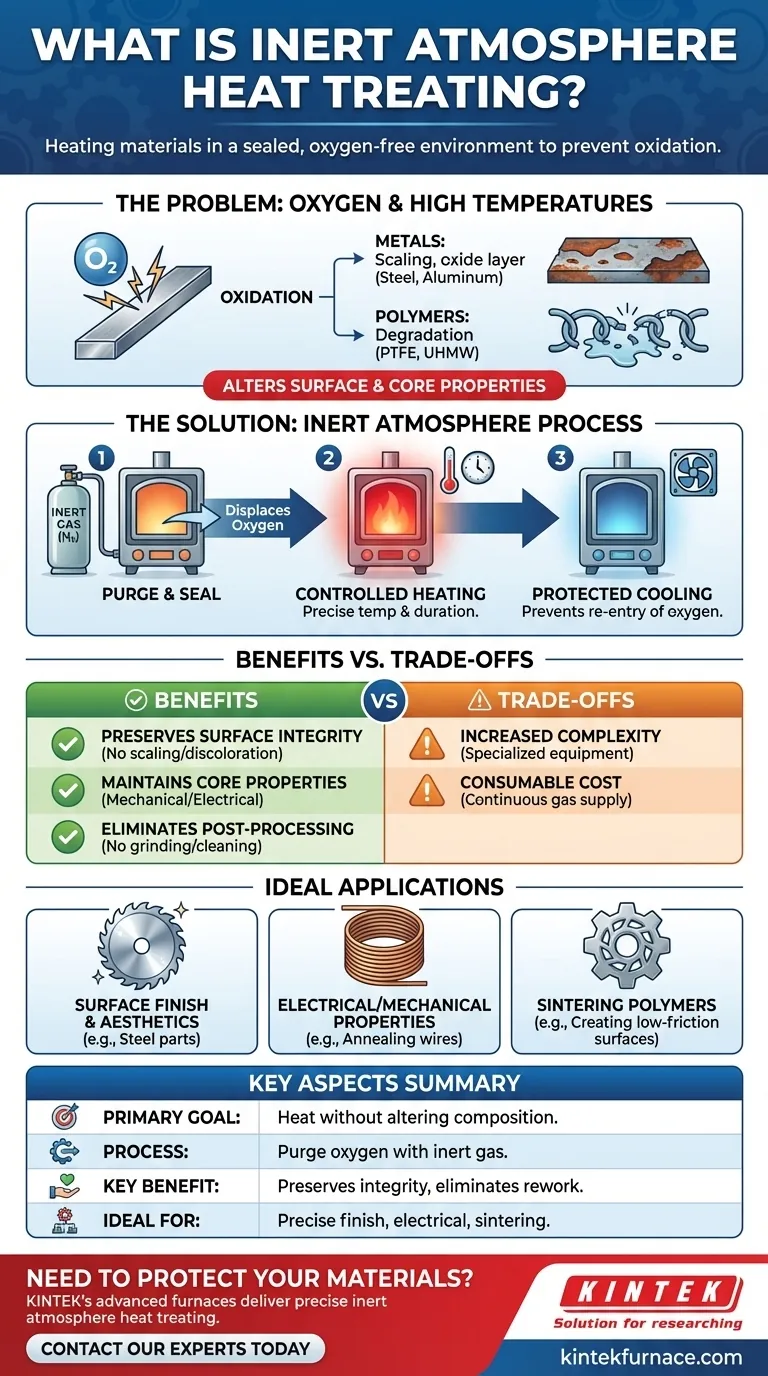

The Core Problem: Why Oxygen Is a Challenge at High Temperatures

The Basics of Oxidation

When most materials are heated in the presence of oxygen, they react chemically in a process called oxidation. This reaction can fundamentally change the surface and properties of the material, often for the worse.

The Impact on Metals

For steel, this manifests as scaling—a flaky, dark oxide layer that forms above 450°F (232°C), ruining the surface finish and potentially compromising dimensional tolerances.

For aluminum, its naturally protective oxide layer thickens significantly at high temperatures. This can make the material unsuitable for certain electrical, brazing, or finishing applications.

The Effect on Specialized Polymers

Even advanced plastics like PTFE (Teflon) and UHMW polyethylene are not immune to this effect. Oxygen can degrade these polymers when heated, compromising their desired properties, such as low friction, during processes like sintering.

How the Inert Atmosphere Process Works

Step 1: Purging the Environment

The process begins by flooding the furnace or oven with an inert gas, most commonly nitrogen. This "cover gas" displaces the oxygen-rich air until a safe, minimal oxygen level is achieved.

Step 2: Controlled Heating

Once the environment is inert, the heating cycle begins. Temperatures are carefully controlled and held for a specific duration based on the material's unique metallurgical or chemical requirements.

Step 3: Protected Cooling

Crucially, the inert atmosphere is also maintained during the cooling cycle. This prevents oxygen from re-entering the chamber and oxidizing the material while it is still hot and chemically reactive.

Understanding the Trade-offs

Increased Process Complexity

Operating an inert atmosphere furnace requires specialized equipment to create and maintain a sealed, oxygen-free environment. This adds a layer of complexity and control compared to simply heating parts in an open-air furnace.

The Cost of Consumables

The process requires a continuous supply of inert gas, such as nitrogen, which is an ongoing operational cost. This expense must be factored into the total cost of manufacturing a component.

The Tangible Benefits of an Inert Atmosphere

Preserving Surface Integrity

The primary benefit is the complete prevention of oxidation. This preserves the material's original surface quality, appearance, and finish without the need for costly rework.

Maintaining Core Material Properties

By stopping unwanted chemical reactions, the process ensures the material's core mechanical, electrical, and chemical properties remain exactly as intended.

Eliminating Post-Processing Steps

Because there is no scale or unwanted oxide layer to remove, inert atmosphere treatment often eliminates the need for secondary steps like grinding, sandblasting, or chemical cleaning.

Making the Right Choice for Your Application

The decision to use inert atmosphere heat treating is driven entirely by the final performance and quality requirements of the component.

- If your primary focus is surface finish and aesthetics: This process is essential for preventing scaling on steel parts like saw blades or discoloration on other metals.

- If your primary focus is preserving electrical or mechanical properties: This is critical for processes like annealing aluminum wires or treating sensitive steel components like gun barrels.

- If your primary focus is sintering high-performance polymers: An inert atmosphere is non-negotiable for preventing the degradation of materials like PTFE to create low-friction surfaces.

Ultimately, employing an inert atmosphere is a strategic choice to guarantee that the material you put into the furnace is the same quality as the material you take out.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Heat materials without altering surface or chemical composition. |

| Process | Purging oxygen with inert gas (e.g., nitrogen) before, during, and after heating. |

| Key Benefit | Preserves surface integrity, material properties, and eliminates post-processing. |

| Ideal For | Applications requiring precise finish, electrical properties, or sintering polymers. |

Need to protect your materials from oxidation during high-temperature processing?

KINTEK's advanced high-temperature furnaces, including our Vacuum & Atmosphere and Tube Furnaces, are engineered to deliver precise, reliable inert atmosphere heat treating. Our strong in-house customization capabilities ensure your specific material and process requirements are met exactly.

Contact our experts today to discuss how we can help you achieve superior material quality and eliminate costly rework.

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity