At its core, a batch-type controlled atmosphere furnace operates by heating a single, isolated workload in a tightly sealed chamber. Instead of a continuous flow of materials, the entire "batch" is loaded, processed under a specific gas environment and precise temperature, and then unloaded, ensuring every piece receives identical treatment.

The fundamental purpose is to isolate a material from the ambient air (oxygen and nitrogen) during heat treatment. By replacing the air with a specific, controlled gas mixture, the furnace prevents unwanted chemical reactions like oxidation and enables the precise material transformations required for advanced manufacturing and research.

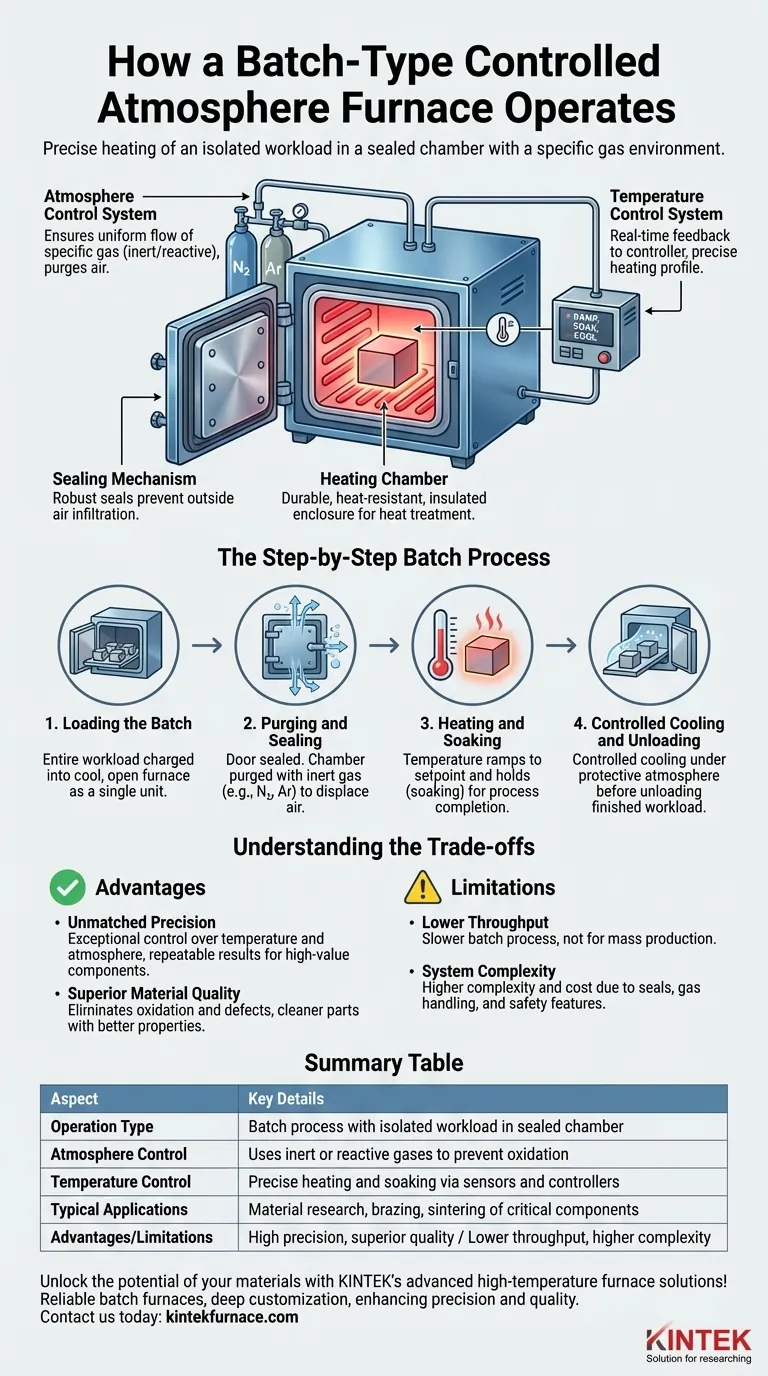

The Core Components and Their Roles

The operation of the furnace is best understood by examining its key components, each designed to manage a critical variable: the workload, the atmosphere, and the temperature.

The Heating Chamber

This is the central enclosure where the heat treatment occurs. It is constructed from highly durable, heat-resistant materials like refractory ceramics or metals to withstand extreme temperatures while providing excellent insulation. Chamber sizes can range from small laboratory models to large industrial units.

The Sealing Mechanism

Airtight integrity is paramount. The furnace door and any ports for sensors or gas lines are equipped with robust seals. This mechanism prevents outside air from infiltrating the chamber and contaminating the controlled atmosphere, which would compromise the entire process.

The Atmosphere Control System

This system introduces, maintains, and purges gases within the chamber. It ensures a uniform flow of a specific gas or gas mixture (such as argon, nitrogen, hydrogen, or others) to create either a protective (inert) or reactive environment. It's the "controlled atmosphere" part of the name.

The Temperature Control System

Using temperature sensors like thermocouples, this system provides real-time feedback to a controller. The controller then automatically adjusts the power supplied to the heating elements, ensuring the temperature inside the chamber precisely follows a pre-programmed heating, soaking, and cooling profile.

The Step-by-Step Batch Process

A typical operational cycle for a batch furnace follows a distinct, sequential process from start to finish.

1. Loading the Batch

The entire workload is charged into the cool, open furnace as a single unit. This is the defining characteristic of a "batch" operation.

2. Purging and Sealing

The furnace door is securely sealed. The system then purges the chamber, removing the ambient air. This is typically done by flooding the chamber with an inert gas like nitrogen or argon, which displaces the oxygen.

3. Heating and Soaking

Once the atmosphere is established, the heating elements activate. The temperature ramps up to a specific setpoint and is held there—a phase known as "soaking"—for a predetermined amount of time to allow the thermal process (like brazing or sintering) to complete fully.

4. Controlled Cooling and Unloading

After the soak is complete, the furnace begins a controlled cooling cycle, often while still maintaining the protective atmosphere to prevent oxidation as the material cools. Once the batch is at a safe temperature, the furnace can be opened and the finished workload is unloaded.

Understanding the Trade-offs

While powerful, these furnaces are not the universal solution for all heating applications. Understanding their specific strengths and limitations is key to using them effectively.

Advantage: Unmatched Precision

By processing a single, static batch, the furnace offers exceptional control over both temperature uniformity and atmospheric consistency. This is critical for high-value components and advanced material research where repeatability is essential.

Advantage: Superior Material Quality

By eliminating oxygen and other contaminants, the furnace prevents oxidation, scaling, and other defects. This results in cleaner parts with superior mechanical or electrical properties.

Limitation: Lower Throughput

The batch process—loading, purging, heating, cooling, unloading—is inherently slower than a continuous process where parts move through different heat zones on a conveyor. It is not designed for high-volume mass production.

Consideration: System Complexity

The need for a tightly sealed chamber, gas handling systems, and advanced safety features (especially when using combustible gases like hydrogen) makes these furnaces more complex and costly to operate than a standard air furnace.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your process requirements for quality, volume, and material properties.

- If your primary focus is high-precision material research: The batch furnace provides the unparalleled environmental control needed for developing new materials and processes.

- If your primary focus is moderate-volume production of critical components: For processes like medical implant sintering or aerospace brazing, a batch furnace delivers the essential quality and consistency.

- If your primary focus is mass production with high throughput: A continuous furnace, which processes parts on a conveyor, is almost always the more efficient and cost-effective solution.

Ultimately, a batch-type controlled atmosphere furnace is a precision tool chosen when the integrity of the material is the most critical factor.

Summary Table:

| Aspect | Key Details |

|---|---|

| Operation Type | Batch process with isolated workload in sealed chamber |

| Atmosphere Control | Uses inert or reactive gases (e.g., argon, nitrogen) to prevent oxidation |

| Temperature Control | Precise heating and soaking via sensors and controllers |

| Typical Applications | Material research, brazing, sintering of critical components |

| Advantages | High precision, superior material quality, repeatability |

| Limitations | Lower throughput, higher complexity and cost |

Unlock the potential of your materials with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable batch-type controlled atmosphere furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing precision and material quality in your processes.

Contact us today to discuss how our solutions can elevate your heat treatment applications and drive your research or production forward!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials