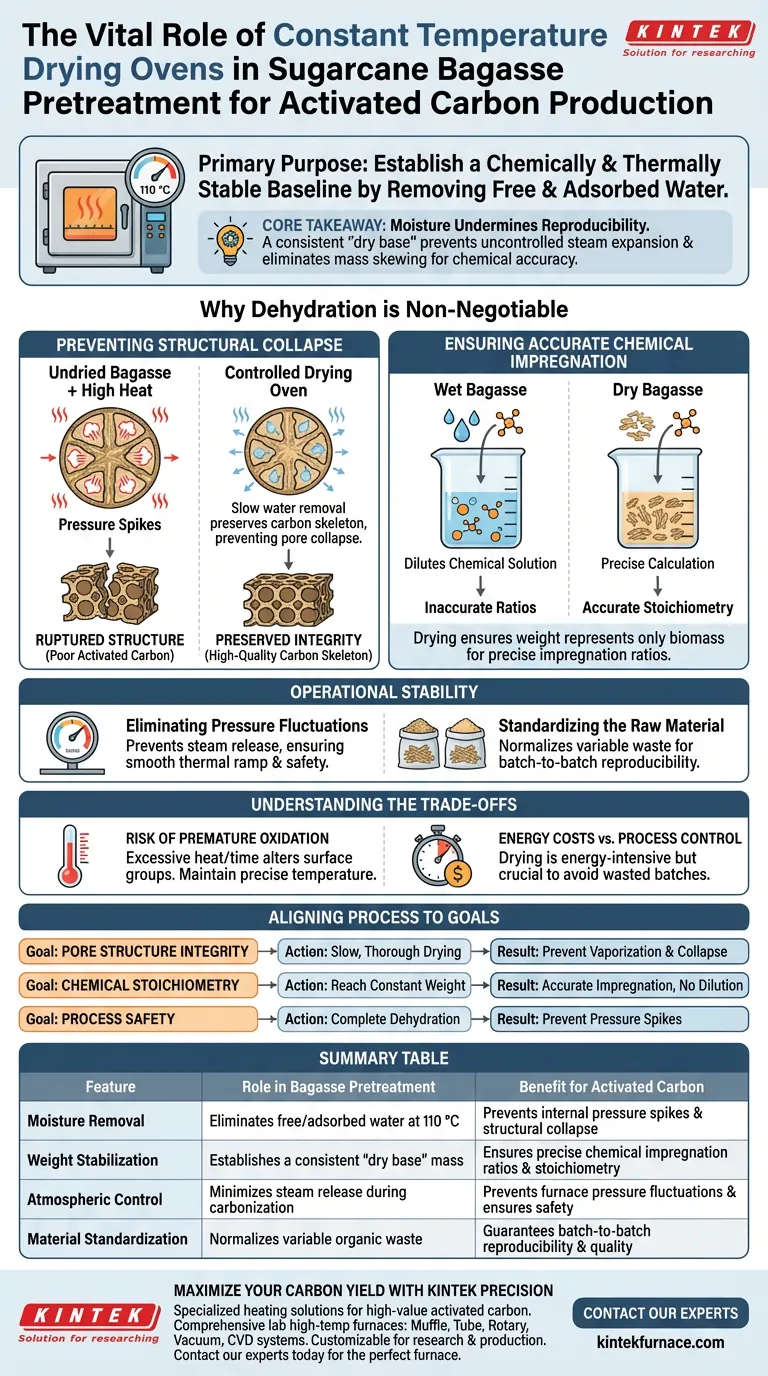

The primary purpose of a constant temperature drying oven in the pretreatment of sugarcane bagasse is to establish a chemically and thermally stable baseline by thoroughly removing free and adsorbed water. Typically operating at 110 °C, this process safeguards the material's physical structure during subsequent high-temperature phases and ensures the accuracy of chemical reagent calculations.

Core Takeaway Moisture is a variable that undermines reproducibility in activated carbon production. By ensuring a consistent "dry base," the drying oven prevents uncontrolled steam expansion that destroys pore structures and eliminates water mass that would otherwise skew the concentration of chemical activators.

Why Pretreatment Dehydration is Non-Negotiable

The drying process is not merely about removing wetness; it is about preparing the biomass microstructure for harsh chemical and thermal environments.

Preventing Structural Collapse

When undried bagasse enters a high-temperature carbonization furnace, residual water turns to steam instantly. This rapid vaporization creates internal pressure spikes that can rupture the cellular structure of the biomass.

By removing water slowly in a controlled oven, you preserve the integrity of the carbon skeleton. This prevents the collapse of the porous structure, which is the defining characteristic of high-quality activated carbon.

Ensuring Accurate Chemical Impregnation

Activated carbon production often involves impregnating the raw material with chemical agents (such as acids or bases). If the bagasse contains unknown amounts of moisture, that water dilutes the chemical solution.

Drying ensures that the weight of the raw material represents only the biomass. This allows for precise calculation of impregnation ratios, ensuring the chemical reaction proceeds exactly as designed.

Operational Stability in Downstream Processing

Beyond the quality of the final product, drying is essential for the safety and stability of the manufacturing equipment.

Eliminating Pressure Fluctuations

The primary reference highlights that drying prevents pressure fluctuations during pre-carbonization. Sudden releases of steam from wet biomass can destabilize the internal atmosphere of a furnace.

removing this variable beforehand ensures a smooth, predictable thermal ramp during the carbonization phase.

Standardizing the Raw Material

Sugarcane bagasse is an organic waste product with highly variable initial moisture content. Processing it immediately without drying would lead to inconsistent results between batches.

A constant temperature oven creates a standardized starting point. Whether the raw supply is slightly damp or soaked, the output of the oven is consistent, ensuring experimental and production reproducibility.

Understanding the Trade-offs

While essential, the drying process requires careful management to avoid damaging the precursor material.

The Risk of Premature Oxidation

While 105 °C to 110 °C is standard, excessively high temperatures or prolonged exposure can lead to surface oxidation. This can alter the surface functional groups of the biomass before activation even begins.

It is critical to maintain the temperature precisely to remove water without initiating chemical degradation of the organic material.

Energy Costs vs. Process Control

Drying is an energy-intensive step that adds time to the production cycle, often requiring 12 to 24 hours. However, skipping this step to save energy often results in wasted batches due to poor pore development or structural failure.

Making the Right Choice for Your Goal

The specific parameters of your drying process should align with your critical quality attributes.

- If your primary focus is Pore Structure Integrity: Prioritize slow, thorough drying to prevent rapid vaporization and skeleton collapse during carbonization.

- If your primary focus is Chemical Stoichiometry: Ensure the material reaches a constant weight to guarantee that residual moisture does not dilute your activating agents.

- If your primary focus is Process Safety: Verify complete dehydration to prevent dangerous pressure spikes in sealed high-temperature reactors.

The drying oven transforms variable organic waste into a reliable, engineering-grade precursor ready for precision activation.

Summary Table:

| Feature | Role in Bagasse Pretreatment | Benefit for Activated Carbon |

|---|---|---|

| Moisture Removal | Eliminates free and adsorbed water at 110 °C | Prevents internal pressure spikes and structural collapse |

| Weight Stabilization | Establishes a consistent "dry base" mass | Ensures precise chemical impregnation ratios and stoichiometry |

| Atmospheric Control | Minimizes steam release during carbonization | Prevents furnace pressure fluctuations and ensures safety |

| Material Standardization | Normalizes variable organic waste | Guarantees batch-to-batch reproducibility and quality |

Maximize Your Carbon Yield with KINTEK Precision

Achieving the perfect pore structure starts with rigorous thermal pretreatment. At KINTEK, we provide the specialized heating solutions needed to transform raw biomass into high-value activated carbon.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production requirements. Whether you are optimizing dehydration protocols or scaling up carbonization, our equipment delivers the temperature stability your process demands.

Ready to elevate your material science? Contact our technical experts today to find the perfect furnace for your laboratory.

Visual Guide

References

- Kyfti Yolanda Siburian, Agung Nugroho. Effect of CoO loading on electrochemical properties of activated carbon from sugarcane bagasse. DOI: 10.5599/jese.2439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the risk mitigation strategies for atmosphere furnace operation? Ensure Safe and Efficient Lab Processes

- How does high-temperature calcination equipment contribute to the conversion of chicken bones into hydroxyapatite?

- How is an atmosphere box furnace utilized in research on material properties? Unlock Precision in Material Science

- What is the significance of a controlled atmosphere in a retort furnace? Ensure Purity and Precision in Thermal Processing

- How does a periodic resistance furnace improve High Vanadium High Speed Steel annealing? Enhance Machinability Today

- What are the typical applications of an atmosphere furnace? Unlock Precision in Metal and Material Processing

- For which materials is the experimental box type atmosphere furnace suitable? Ideal for Metals, Ceramics, and Advanced Materials

- What are the controlled atmospheres for heat treatment? Master the Art of Material Transformation