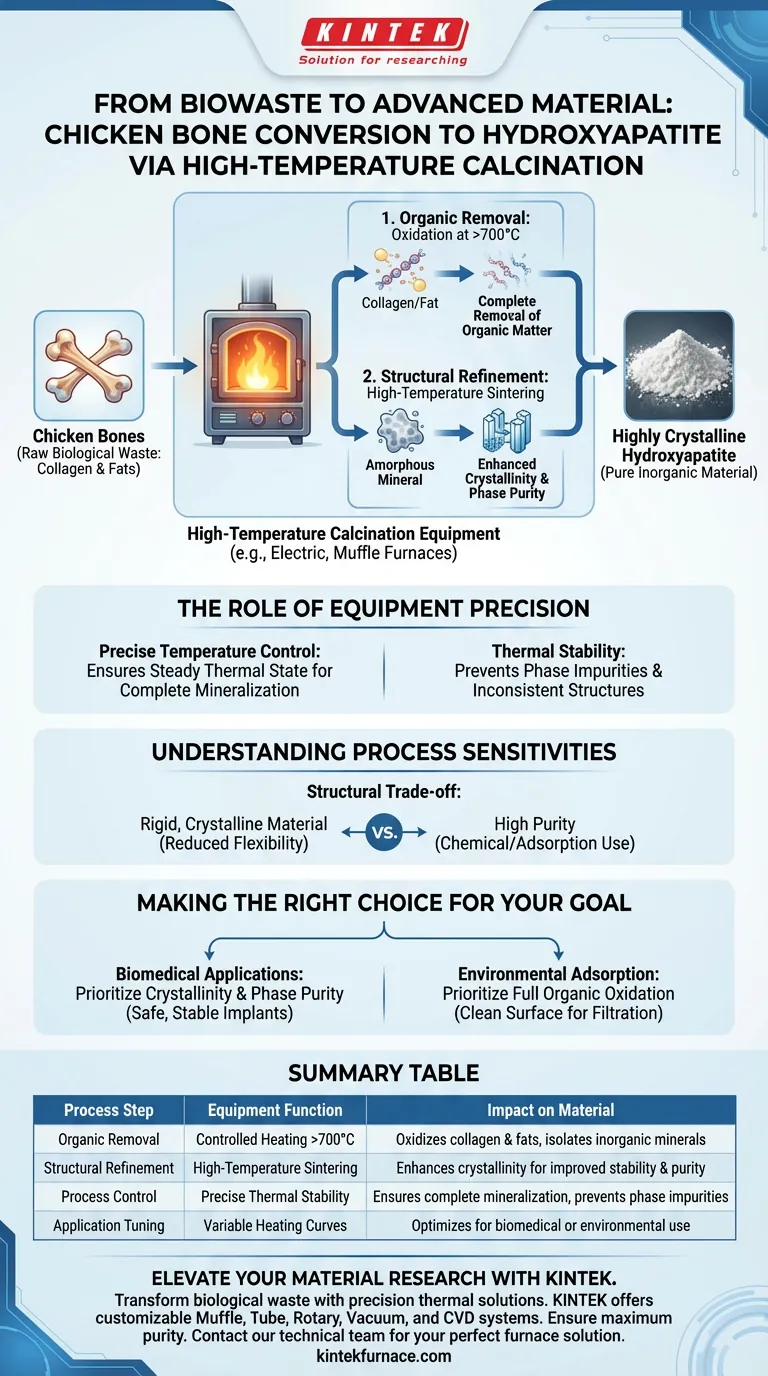

High-temperature calcination equipment serves as the primary mechanism for both purification and structural refinement in the conversion of chicken bones to hydroxyapatite. Specifically, this equipment utilizes electric or muffle furnaces to maintain a constant environment above 700 °C, effectively oxidizing and removing organic materials like collagen and fats to isolate the inorganic mineral.

By providing a controlled thermal environment, this equipment transforms raw biological waste into a highly crystalline, pure inorganic material suitable for advanced biomedical and environmental applications.

The Mechanism of Purification and Synthesis

Complete Removal of Organic Matter

The primary function of the calcination equipment is to eliminate the biological matrix of the bone. Chicken bones are composites containing significant amounts of organic components, specifically collagen and fats.

By sustaining temperatures above 700 °C, the furnace ensures the complete oxidation of these organic substances. This process leaves behind only the inorganic mineral structure, which is the precursor for pure hydroxyapatite.

Enhancement of Crystallinity

Beyond simple purification, the equipment drives the structural evolution of the material. The application of high heat transforms the raw bone mineral into a highly crystalline form.

This physical change is critical for the material's end-use. Higher crystallinity typically correlates with better stability and suitability for high-value applications.

The Role of Equipment Precision

Precise Temperature Control

The quality of the resulting hydroxyapatite is heavily dependent on the equipment's ability to maintain a steady thermal state. Devices such as electric furnaces, tube furnaces, or muffle furnaces are designed to provide this constant high-temperature environment.

Influencing Material Purity

The capability of the equipment to dictate heating curves and constant temperature durations directly influences the final purity of the product.

Precise control facilitates the necessary diffusion and chemical reactions within the material. This ensures complete mineralization and prevents phase impurities that could compromise the material's performance.

Understanding Process Sensitivities

The Necessity of Thermal Stability

While high temperatures are required, the process relies on the stability of that heat. Fluctuations or inability to hold the specific temperature setpoint can result in incomplete removal of organics or inconsistent crystal structures.

Structural Trade-offs

The calcination process creates a highly pure inorganic mineral, but it involves the total destruction of the organic matrix.

This results in a material that is rigid and crystalline, lacking the flexibility of natural bone. This trade-off is intentional and necessary to produce hydroxyapatite suitable for chemical synthesis or adsorption, but it fundamentally alters the mechanical properties of the original raw material.

Making the Right Choice for Your Goal

The specific application of your hydroxyapatite dictates how you should utilize calcination equipment.

- If your primary focus is Biomedical Applications: Prioritize equipment with high-precision temperature control to maximize crystallinity and phase purity, ensuring the material is safe and stable for biological use.

- If your primary focus is Environmental Adsorption: Focus on the equipment's ability to fully oxidize organic contaminants, ensuring the resulting mineral has a clean surface area for effective filtration.

Success in this conversion process relies not just on heat, but on the precise control of that heat to engineer the specific crystal structure you require.

Summary Table:

| Process Step | Equipment Function | Impact on Material |

|---|---|---|

| Organic Removal | Controlled Heating >700°C | Oxidizes collagen and fats to isolate inorganic minerals |

| Structural Refinement | High-Temperature Sintering | Enhances crystallinity for improved stability and purity |

| Process Control | Precise Thermal Stability | Ensures complete mineralization and prevents phase impurities |

| Application Tuning | Variable Heating Curves | Optimizes material for biomedical use or environmental filtration |

Elevate Your Material Research with KINTEK

Are you looking to transform biological waste into high-value hydroxyapatite? KINTEK provides the precision thermal solutions necessary for sensitive calcination processes. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique research or production needs.

Ensure maximum purity and crystallinity in your samples today. Contact our technical team to find your perfect furnace solution.

Visual Guide

References

- Mircea Gabriel Macavei, Aneta Magdziarz. Thermochemical Conversion of Animal-Derived Waste: A Mini-Review with a Focus on Chicken Bone Waste. DOI: 10.3390/pr12020358

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What processing conditions must a high-temperature homogenization furnace provide? Eliminate Dendritic Segregation

- What is the purpose of switching between N2 and H2 in electrical steel annealing? Master Atmosphere Control

- What is the purpose of pre-heating industrial-grade ceramic molds? Ensure Perfect Grain Structures and Casting Yield

- What are the cost considerations when using argon in heat treatment? Maximize Savings and Quality

- What problems arise when ordinary metal materials are heated in an air furnace? Avoid Oxidation and Embrittlement

- Why is a continuous argon flow necessary during the thermal treatment of graphite? Achieve 2400 °C Ultra-Deep Purification

- Why use multi-stage temperature control for REBCO pyrolysis? Prevent 75% Shrinkage Cracks and Ensure Film Density

- Why is a sealed environment important in a controlled atmosphere furnace? Ensure Precision and Safety in High-Temp Processes