The fundamental significance of a controlled atmosphere in a retort furnace is to create a chemically isolated and highly stable environment for thermal processing. By using a sealed vessel—the retort—it physically separates the material from the heating elements and outside air, preventing oxidation, contamination, and other unwanted reactions that would degrade the final product.

A retort furnace is not simply a tool for heating; it is a system for precise environmental control. Its sealed design offers a superior level of atmospheric purity and gas efficiency, which is essential for high-specification material treatments where product quality is paramount.

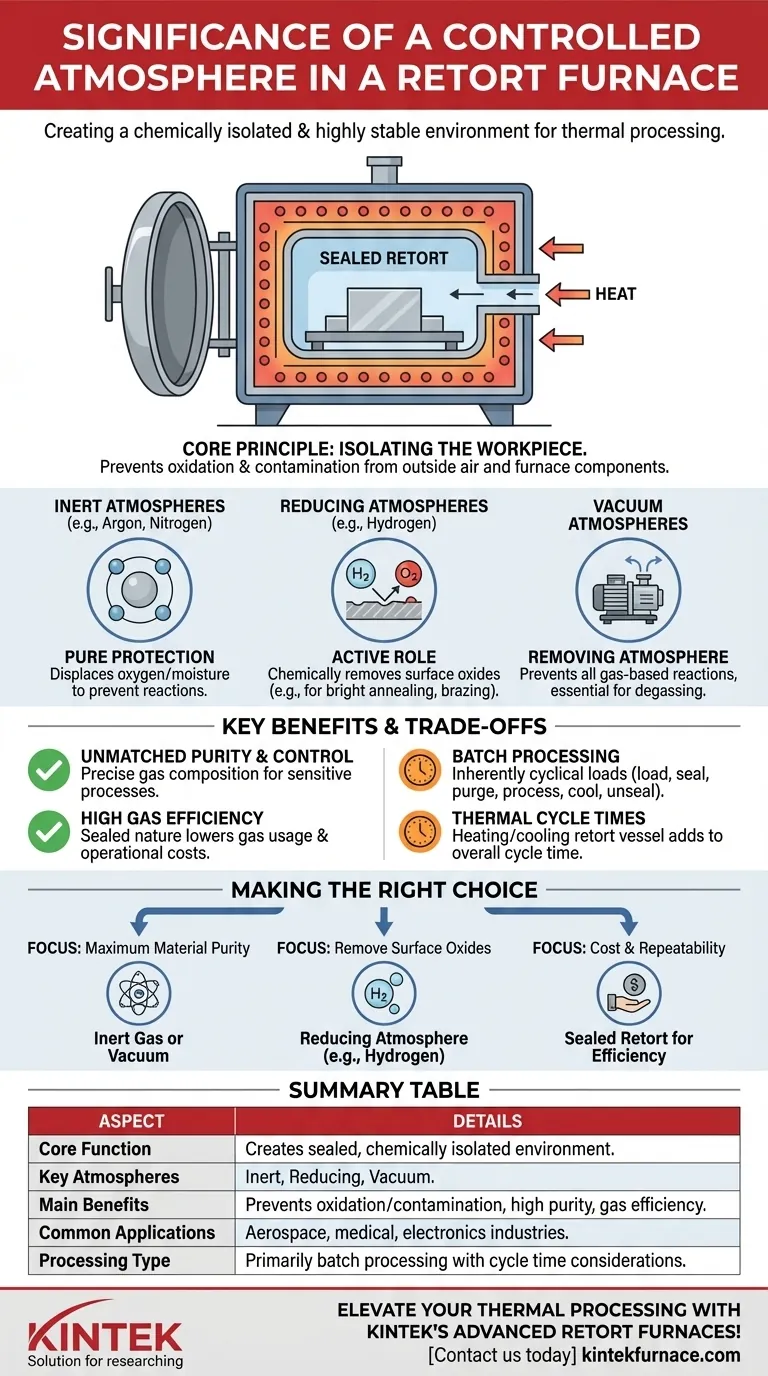

The Core Principle: Isolating the Workpiece

A retort furnace's unique advantage comes from its core design philosophy: total separation of the process environment from the heating system.

The Role of the Sealed Retort

The "retort" is a sealed chamber, typically made of a high-temperature alloy or ceramic, that holds the material being processed. This chamber is then placed inside the main furnace body to be heated externally.

This physical barrier is the key. It isolates the internal workspace from the furnace's heating elements, insulation, and the ambient factory air.

Preventing Unwanted Reactions

By creating a sealed environment, the retort furnace directly prevents the two most common sources of product failure during heat treatment: oxidation from ambient air and contamination from furnace components.

This ensures the chemical and physical properties of the material are altered only by the intended thermal process, not by random, uncontrolled reactions.

How Atmospheres Achieve Specific Outcomes

The "controlled atmosphere" is the specific gas or vacuum intentionally introduced into the sealed retort to achieve a desired chemical outcome.

Inert Atmospheres (e.g., Argon, Nitrogen)

An inert atmosphere is used for pure protection. Gases like argon do not react with the material being heated.

Their purpose is simply to displace all oxygen and moisture, creating a neutral environment that prevents oxidation and other reactions from occurring.

Reducing Atmospheres (e.g., Hydrogen)

A reducing atmosphere plays a more active role. Gases like hydrogen will chemically react with and remove oxides from the surface of the material.

This is critical for processes like bright annealing or brazing, where a perfectly clean, oxide-free surface is required for the material's final properties or for a strong metallurgical bond.

Vacuum Atmospheres

Removing the atmosphere entirely is another powerful method of control. Processing under a vacuum is ideal for preventing all gas-based reactions and is essential for processes like degassing, where trapped gases must be removed from the material itself.

Understanding the Key Benefits and Trade-offs

While powerful, the retort design has specific advantages and practical considerations that influence its suitability for a given process.

Benefit: Unmatched Purity and Control

Because the retort is a closed, sealed system, it allows for extremely precise control over the gas composition. This is critical for sensitive processes in the aerospace, medical, and electronics industries where even trace amounts of contamination can cause failure.

Benefit: High Gas Efficiency

The sealed nature of the retort means that once the desired atmosphere is established, very little gas is needed to maintain it. This results in significantly lower atmosphere usage and operational costs compared to continuous furnaces that require constant purging to keep contaminants out.

Consideration: Batch Processing

Retort furnaces are most commonly used for batch processing. The need to load, seal, purge, process, cool, and unseal the chamber makes it inherently cyclical. While continuous retort designs exist, the classic retort is optimized for treating individual loads.

Consideration: Thermal Cycle Times

The retort vessel itself has thermal mass and must be heated and cooled along with the workload. This can sometimes lead to longer overall cycle times compared to placing a part directly into an already hot furnace zone.

Making the Right Choice for Your Process

Your specific process goal will determine whether a retort furnace is the appropriate tool and which atmosphere is required.

- If your primary focus is maximum material purity and preventing any surface reaction: A retort furnace with a high-purity inert gas (like argon) or a vacuum is the definitive choice.

- If your primary focus is removing existing surface oxides for a "bright" finish: A retort with a reducing atmosphere containing hydrogen is necessary to achieve the desired chemical reaction.

- If your primary focus is operational cost and process repeatability: The low gas consumption and exceptional environmental control of a sealed retort offer significant long-term savings and process stability.

Ultimately, a retort furnace provides the highest degree of atmospheric control, making it an essential tool for processes where material integrity cannot be compromised.

Summary Table:

| Aspect | Details |

|---|---|

| Core Function | Creates a sealed, chemically isolated environment for precise thermal processing. |

| Key Atmospheres | Inert (e.g., Argon, Nitrogen), Reducing (e.g., Hydrogen), Vacuum. |

| Main Benefits | Prevents oxidation and contamination, ensures high purity, and offers gas efficiency. |

| Common Applications | Bright annealing, brazing, degassing in aerospace, medical, and electronics industries. |

| Processing Type | Primarily batch processing with considerations for cycle times. |

Elevate your thermal processing with KINTEK's advanced retort furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering unmatched purity, efficiency, and cost savings. Contact us today to discuss how our high-temperature furnace solutions can optimize your processes and safeguard material integrity!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance