In short, the experimental box type atmosphere furnace is designed for a versatile range of materials that require high-temperature processing within a controlled, non-oxidizing environment. This includes metals like steel, copper, and aluminum alloys; technical ceramics and glass; and advanced materials such as nanomaterials and composites.

The suitability of a box type atmosphere furnace is determined less by the material itself and more by the process. It is the ideal choice for any material that needs precise heat treatment at high temperatures without reacting with oxygen.

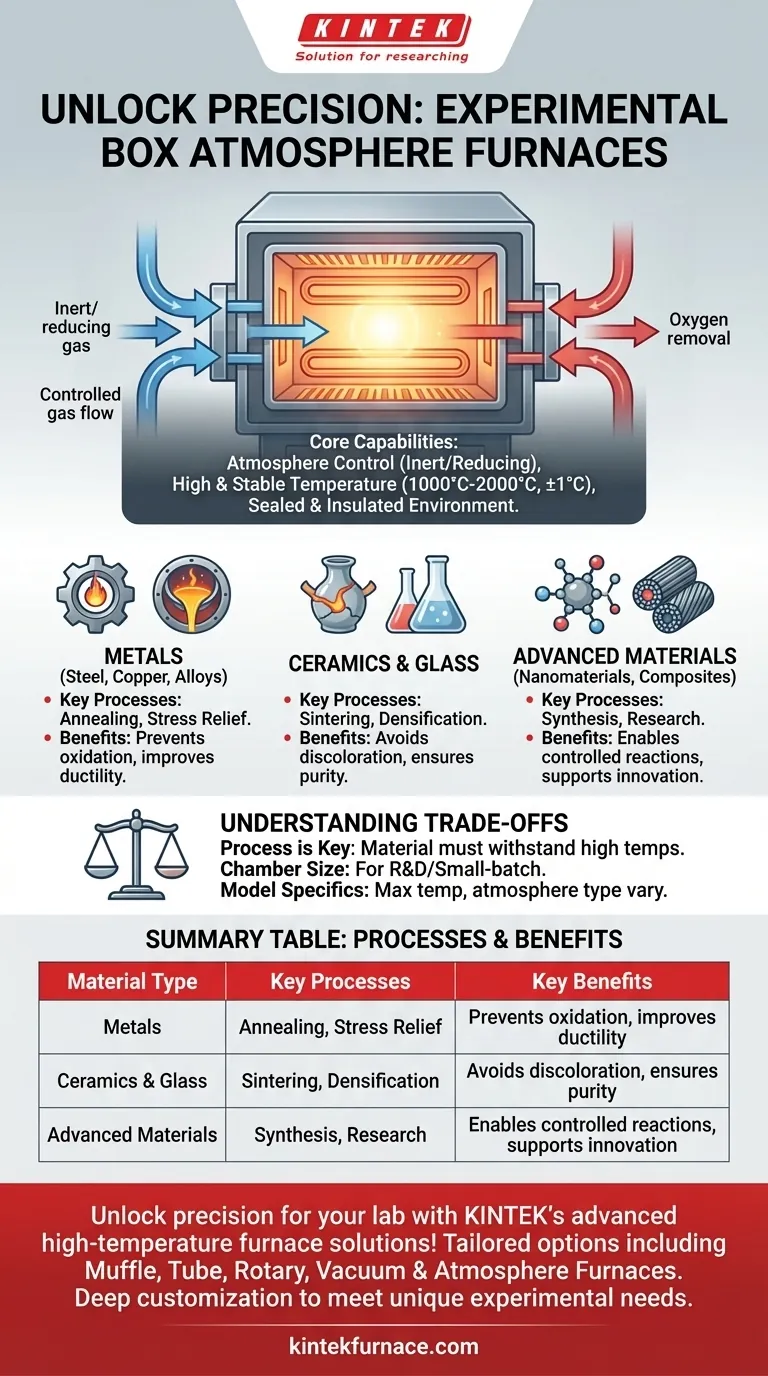

What Makes a Material Suitable? The Core Capabilities

The furnace's value comes from its ability to create a highly specific, repeatable environment. This is achieved through three core functions that directly determine which materials and processes are a match.

The Power of Atmosphere Control

A box type atmosphere furnace allows you to replace the ambient air with a specific gas, creating an inert or reducing atmosphere.

This is critical for materials that would otherwise oxidize (rust or tarnish) at high temperatures. By removing oxygen, the furnace protects the material's surface and internal properties.

High and Stable Temperature Regulation

These furnaces operate at very high temperatures, often from 1000°C to 2000°C, with exceptional stability. Advanced models can maintain a set temperature with a precision of ±1°C.

This stability is essential for sensitive thermal processes like annealing metals to relieve stress or sintering ceramic powders into a solid mass, where slight temperature deviations can ruin the result.

A Sealed and Insulated Environment

The furnace chamber is sealed to prevent the controlled atmosphere from escaping or outside air from entering.

High-performance insulation, typically made of ceramic or aluminum silicate fibers, ensures minimal heat loss. This provides energy efficiency and helps maintain the extreme temperature stability required for reliable experiments.

Common Applications by Material Type

Understanding how the furnace's capabilities are applied to specific material classes clarifies its purpose.

For Metals (Steel, Copper, Aluminum Alloys)

The most common application for metals is annealing. Heating a metal in an inert atmosphere removes internal stresses introduced during manufacturing, making the metal softer and more ductile without creating a layer of oxide scale.

This process is vital for preparing metals for further forming or to achieve their final desired mechanical properties.

For Ceramics and Glass

In ceramics manufacturing, atmosphere furnaces are used for sintering. This process involves heating compacted ceramic powder to just below its melting point, causing the particles to bond together and form a dense, solid object.

For both ceramics and glass, a controlled atmosphere prevents unwanted chemical reactions that could discolor the material or introduce impurities.

For New Material Research (Nanomaterials, Composites)

For scientists and engineers, the furnace is a critical research tool. Its precise control over both temperature and atmosphere makes it ideal for synthesizing new materials.

Researchers can study how materials behave under extreme conditions or create novel composites and nanomaterials that would be impossible to produce in a normal air environment.

Understanding the Trade-offs and Limitations

While versatile, the box atmosphere furnace is a specialized tool. Understanding its limitations is key to using it effectively.

It's About the Process, Not Just the Material

A material is only suitable if the process it requires matches the furnace's capabilities. Materials that cannot withstand high temperatures or that might react with the furnace's internal insulation are not appropriate.

Chamber Size Dictates Throughput

These are "box type" furnaces, typically designed for experimental, R&D, or small-batch production. Their chamber size limits the volume of material that can be processed at one time, making them unsuitable for large-scale industrial manufacturing.

Model Specifications Matter Most

There is no single furnace for all tasks. The maximum temperature, types of atmospheric gases supported, and chamber dimensions vary significantly between models. A furnace designed for 1200°C metal annealing cannot be used for 1700°C ceramic sintering.

Making the Right Choice for Your Application

Select a furnace based on the specific requirements of your thermal process.

- If your primary focus is metal heat treatment: Ensure the furnace's atmosphere control (inert or reducing gas) and temperature range are appropriate to prevent oxidation and achieve the desired properties for your specific alloy.

- If your primary focus is ceramic or glass processing: Confirm the furnace's maximum temperature and stability (e.g., ±1°C) meet the precise requirements for sintering, densification, or annealing.

- If your primary focus is new material research: Prioritize a model with flexible atmosphere options and precise temperature programming to accommodate the diverse and evolving needs of your experiments.

Ultimately, the furnace's suitability is defined not just by the material, but by the precise high-temperature process you need to perform.

Summary Table:

| Material Type | Key Processes | Key Benefits |

|---|---|---|

| Metals (e.g., steel, copper, aluminum alloys) | Annealing, stress relief | Prevents oxidation, improves ductility |

| Ceramics and Glass | Sintering, densification | Avoids discoloration, ensures purity |

| Advanced Materials (e.g., nanomaterials, composites) | Synthesis, research | Enables controlled reactions, supports innovation |

Unlock precision for your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs—whether for metals, ceramics, or nanomaterials. Contact us today to enhance your processes and achieve reliable results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance