In materials research, an atmosphere box furnace is a critical tool used to precisely control both temperature and the surrounding chemical environment during heat treatment. This dual control allows researchers to simulate specific conditions, prevent unwanted chemical reactions like oxidation, and deliberately alter a material's microstructure and properties to study its fundamental behavior or develop new, improved materials.

The core value of an atmosphere furnace is its ability to decouple the effects of heat from the effects of the surrounding air. By creating a controlled, oxygen-free, or reactive gas environment, it allows researchers to observe how a material truly behaves at high temperatures or to guide its transformation with surgical precision.

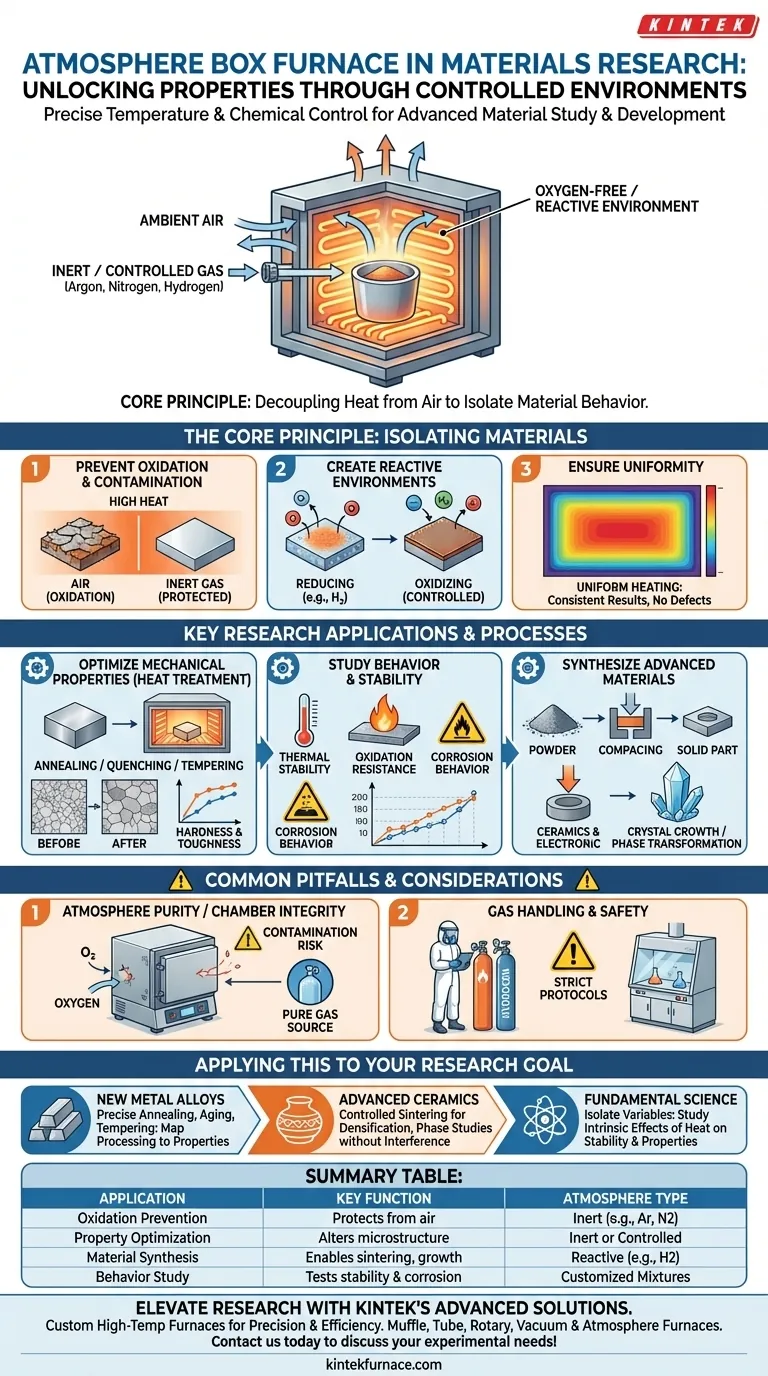

The Core Principle: Isolating Material from Atmosphere

The fundamental purpose of an atmosphere furnace is to remove the unpredictable variable of ambient air. This unlocks several key experimental capabilities.

Preventing Unwanted Oxidation and Contamination

Most materials will react with oxygen in the air at high temperatures, a process known as oxidation. This can form a brittle oxide layer on the surface, alter chemical composition, and compromise the material's integrity.

An atmosphere furnace prevents this by first purging the chamber of air and then filling it with an inert gas, such as argon or nitrogen. This creates a neutral environment, ensuring that the changes observed in the material are due to the heat alone, not an unintended chemical reaction.

Creating Controlled Reactive Environments

Beyond just preventing reactions, these furnaces can introduce specific reactive gases to deliberately drive a desired chemical process.

A reducing atmosphere, often containing hydrogen, can be used to remove oxygen from a material's surface. Conversely, a controlled oxidizing atmosphere can be used to study corrosion or create a specific, protective oxide layer.

Ensuring Thermal and Structural Uniformity

A well-designed box furnace provides highly uniform heating throughout the chamber. This consistency is crucial for research, as it ensures that the entire sample undergoes the same thermal cycle, leading to repeatable and reliable results.

This uniformity is essential for achieving consistent grain size, eliminating internal stresses, and preventing defects or unwanted phase transformations within the material.

Key Research Applications and Processes

By precisely managing heat and atmosphere, researchers can execute a wide range of processes to analyze, modify, and create materials.

Optimizing Mechanical Properties via Heat Treatment

Atmosphere furnaces are central to studying and performing heat treatments like annealing, quenching, and tempering, especially for metals and alloys.

For example, a researcher might study the aging characteristics of a new aluminum alloy by heating samples in an inert atmosphere to a specific temperature, holding them for various times, and then testing the resulting hardness and microstructure. This reveals how to optimize the alloy's strength and durability.

Studying Material Behavior and Stability

These furnaces are used to test a material's limits. Researchers can measure properties like thermal stability (the temperature at which it breaks down), oxidation resistance, and corrosion behavior under specific atmospheric conditions.

This data provides the theoretical basis for designing materials that can survive in extreme environments, from jet engines to chemical reactors.

Synthesizing and Processing Advanced Materials

Many advanced materials, particularly ceramics, cannot be created in open air. An atmosphere furnace is essential for processes like sintering, where fine powders are heated to bond together and form a dense, solid part.

It is also used for crystal growth and inducing phase transformations, enabling the creation of materials with unique electronic, optical, or structural properties.

Common Pitfalls and Considerations

While powerful, the effectiveness of an atmosphere furnace depends on careful operation and understanding its inherent limitations.

Atmosphere Purity and Chamber Integrity

The entire process relies on the furnace's ability to maintain a perfectly sealed chamber. Any leaks can introduce oxygen and contaminate the experiment, invalidating the results. The purity of the source gases is equally critical.

Gas Handling and Safety Protocols

Working with reactive gases, especially flammable ones like hydrogen, requires strict safety protocols, specialized equipment, and proper ventilation. These factors add complexity and cost to the experimental setup.

Limited Sample Throughput

Atmosphere box furnaces are primarily designed for batch processing of small samples, making them ideal for research and development. They are not suited for the continuous, high-volume needs of mass production.

Applying This to Your Research Goal

The way you utilize an atmosphere furnace depends directly on your objective.

- If your primary focus is developing new metal alloys: Use the furnace for precise annealing, aging, and tempering studies to map how processing parameters influence mechanical properties like hardness and toughness.

- If your primary focus is advanced ceramics: The furnace is non-negotiable for controlled sintering to achieve full densification and for studying phase transformations without atmospheric interference.

- If your primary focus is fundamental material science: Use the furnace to isolate variables, allowing you to study the intrinsic effects of heat on a material's stability, thermal expansion, or gas adsorption properties.

Ultimately, the atmosphere box furnace empowers you to move beyond simply heating a material and instead sculpt its very structure and performance with scientific control.

Summary Table:

| Application | Key Function | Atmosphere Type |

|---|---|---|

| Oxidation Prevention | Protects materials from air reactions | Inert (e.g., Argon, Nitrogen) |

| Property Optimization | Alters microstructure via heat treatment | Inert or Controlled |

| Material Synthesis | Enables sintering and crystal growth | Reactive (e.g., Hydrogen) |

| Behavior Study | Tests thermal stability and corrosion | Customized Gas Mixtures |

Elevate your material research with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your lab's precision and efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process