High-purity graphite is the preferred material for stirrer blades in silicon melt monitoring because it uniquely balances thermal resilience with chemical inertness. It withstands temperatures up to 1450°C and thermal shock without structural failure, while simultaneously preventing the introduction of metallic impurities into the sensitive silicon melt.

Core Insight: Successful silicon melt monitoring relies on minimizing contamination while maximizing equipment lifespan. High-purity graphite is the industry standard because it acts as a chemically neutral agent that can survive extreme thermal fluctuations that would fracture other materials.

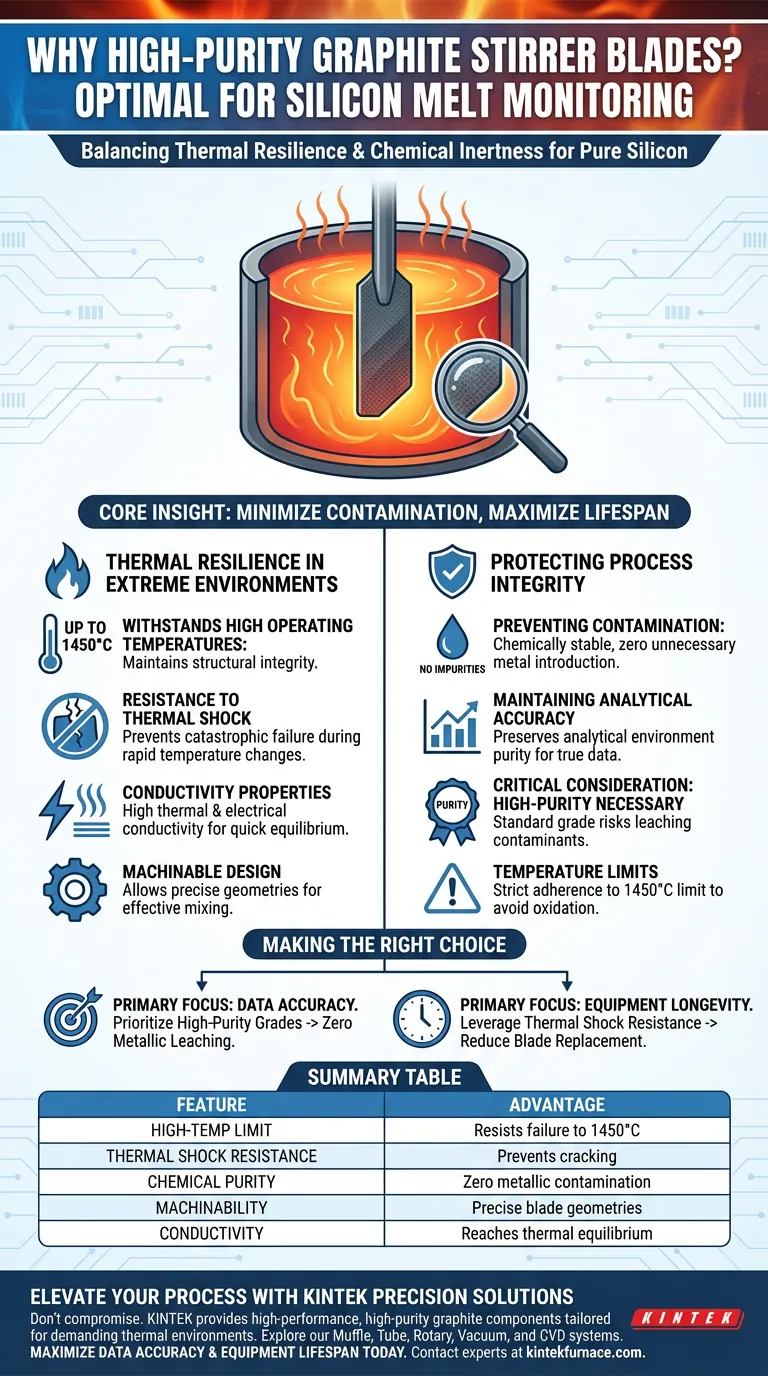

Thermal Resilience in Extreme Environments

Withstanding High Operating Temperatures

The monitoring of silicon melt requires equipment to survive in an aggressive thermal environment. High-purity graphite demonstrates exceptional high-temperature resistance, maintaining structural integrity up to 1450°C.

Resistance to Thermal Shock

A critical advantage of graphite over many ceramics is its ability to withstand rapid temperature changes. It resists extreme thermal shocks without cracking, which prevents catastrophic blade failure during the insertion or removal process.

Conductivity Properties

Graphite offers high thermal and electrical conductivity. This ensures the stirrer blade reaches thermal equilibrium with the melt quickly and does not interfere with the electrical properties of the monitoring setup.

Protecting Process Integrity

Preventing Contamination

In silicon production, purity is paramount. High-purity graphite is chemically stable, ensuring that no unnecessary metal impurities are introduced into the melt.

Maintaining Analytical Accuracy

By preventing contamination, graphite preserves the purity of the analytical environment. This ensures that the data collected during online monitoring reflects the true state of the silicon, rather than artifacts caused by equipment degradation.

Machinability and Design

Graphite is a highly machinable material. This allows manufacturers to craft stirrer blades with precise geometries required for effective mixing and monitoring, a flexibility often lacking in harder, more brittle refractory materials.

Critical Considerations and Constraints

The Necessity of Purity

Not all graphite is suitable for this application. The material must be high-purity; using standard-grade graphite poses a severe risk of leaching contaminants into the silicon melt, compromising the end product.

Temperature Limits

While graphite is robust, the primary reference notes a specific operating context of 1450°C. Exceeding the material's rated thermal limits in an uncontrolled environment could lead to oxidation or degradation, necessitating strict adherence to operational parameters.

Making the Right Choice for Your Goal

To ensure the success of your silicon melt monitoring project, select your materials based on your specific operational priorities:

- If your primary focus is Data Accuracy: Prioritize high-purity grades of graphite to ensure zero metallic leaching and an uncompromised analytical environment.

- If your primary focus is Equipment Longevity: Leverage graphite’s thermal shock resistance to reduce the frequency of blade replacement caused by cracking during temperature cycling.

High-purity graphite remains the definitive choice for balancing the mechanical demands of high-heat environments with the strict chemical requirements of silicon processing.

Summary Table:

| Feature | Advantage for Silicon Melt Monitoring |

|---|---|

| High-Temp Limit | Resists structural failure up to 1450°C |

| Thermal Shock Resistance | Prevents cracking during rapid insertion or removal |

| Chemical Purity | Ensures zero metallic contamination of the silicon melt |

| Machinability | Allows for precise blade geometries for effective mixing |

| Conductivity | Reaches thermal equilibrium quickly with the melt |

Elevate Your Process with KINTEK Precision Solutions

Don't compromise your silicon purity with inferior materials. KINTEK provides high-performance, high-purity graphite components tailored for the most demanding thermal environments. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of laboratory equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which can be customized to your specific high-temperature monitoring needs.

Maximize your data accuracy and equipment lifespan today. Contact our technical experts at KINTEK to discuss your custom furnace and material requirements!

Visual Guide

References

- Younès Belrhiti, Amal Chabli. Mechanical stirring: Novel engineering approach for in situ spectroscopic analysis of melt at high temperature. DOI: 10.1016/j.heliyon.2024.e25626

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do MoSi2 heating elements resist oxidation? Unlock the Secret to High-Temperature Durability

- What are the typical applications of Molybdenum Disilicide (MoSi₂)? Unlock High-Temp Heating Solutions

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the common sheath materials for heating elements and their properties? Choose the Best for Your Lab's Needs

- What information is needed to determine the size of a U-shaped heating element? Ensure Proper Fit and Performance

- What are ceramic heating elements and what are their key characteristics? Discover High-Performance Heating Solutions

- What maintenance considerations are important for furnace heating elements? Ensure Longevity and Reliability

- What is a heating element? The Engine of Controlled Heat for Your Applications