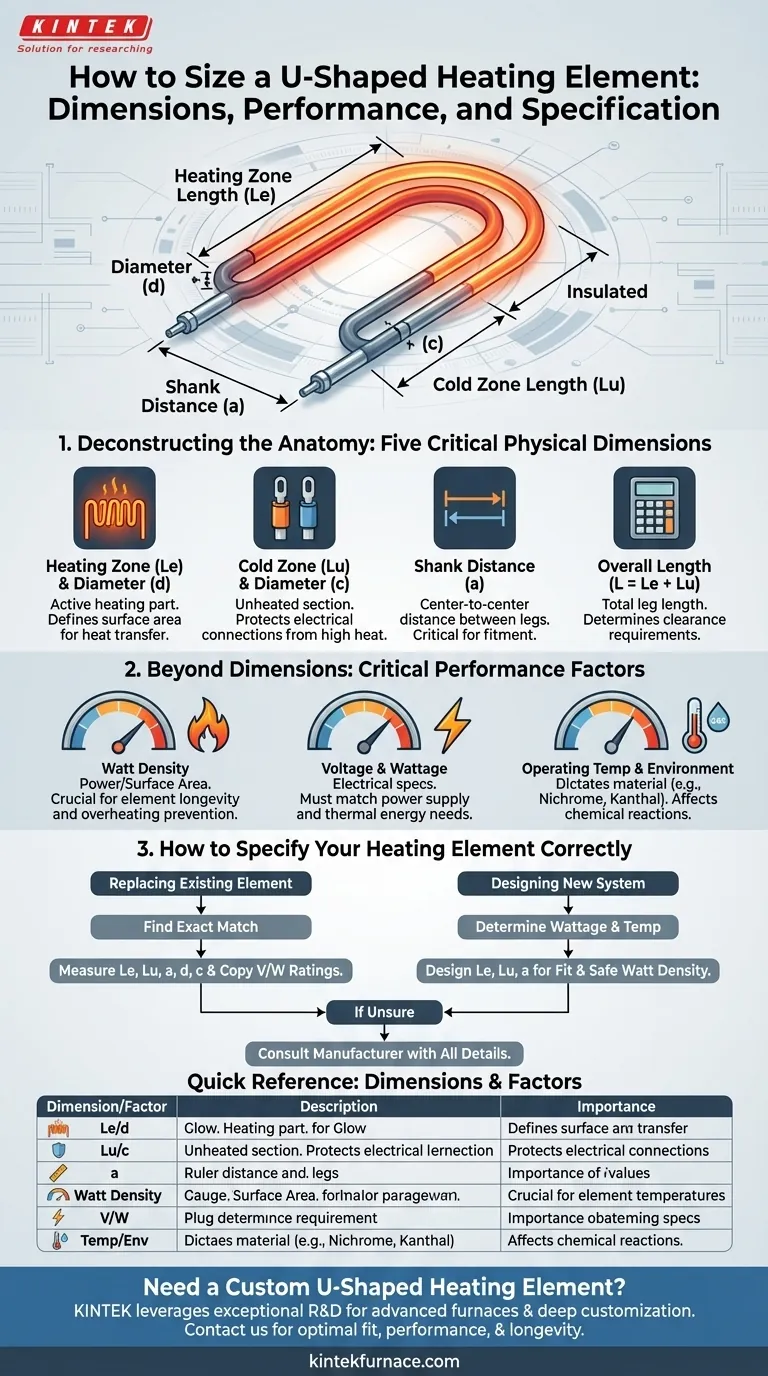

To correctly size a U-shaped heating element, you must define five critical physical dimensions. These are the heating zone length (Le), the cold zone length (Lu), the shank distance (a), the heating zone diameter (d), and the cold zone diameter (c). These measurements ensure the element not only fits physically within your equipment but also operates safely and effectively.

Sizing a heating element goes beyond simple physical measurements. The true goal is to match the element's dimensions and material properties to the specific thermal demands of your application, ensuring both proper fit and optimal heating performance without premature failure.

Deconstructing the Element's Anatomy

Understanding what each dimension represents is crucial for selecting or designing the right component. These measurements define the element's physical form and how it interfaces with your equipment.

The Heating Zone (Le) and Diameter (d)

This is the active portion of the element that glows and produces heat. The heating zone length (Le) and diameter (d) together determine the element's total surface area.

This surface area is a critical factor in how intensely the element transfers heat into your chamber or process.

The Cold Zone (Lu) and Diameter (c)

The cold zone length (Lu), also known as the terminal length, is the unheated section at each end of the element. Its primary purpose is to pass through the insulated wall of a furnace or oven.

This length must be sufficient to keep the electrical connection terminals safely outside the high-temperature zone, preventing damage to the wiring and connection points. The cold zone diameter (c) may differ from the heating zone for structural support.

The Shank Distance (a)

This is the center-to-center distance between the two "legs" or shanks of the U-shaped element.

The shank distance (a) is a critical fitment dimension. It must precisely match the spacing of the mounting holes or terminal blocks on your equipment.

The Overall Length (L)

While often calculated rather than specified directly, the overall length of each leg is simply Le + Lu. This total length determines the clearance required inside the heating chamber.

Beyond Dimensions: Critical Performance Factors

A physically correct fit is only half the battle. To ensure the element functions correctly and has a reasonable service life, you must also consider its performance specifications. Omitting these factors is a common and costly mistake.

Watt Density

Watt density is the single most important factor for an element's longevity. It is the total power output (wattage) divided by the surface area of the heating zone (Le x d x π).

If the watt density is too high for the application, the element will overheat and burn out quickly. If it's too low, it may not be able to reach your required process temperature.

Voltage and Wattage

These electrical specifications determine the total amount of heat the element will produce. They must be compatible with your power supply and calculated to deliver the thermal energy your process requires.

Operating Temperature and Environment

The required operating temperature dictates the material the element must be made from (e.g., Nichrome, Kanthal A-1, Silicon Carbide).

Furthermore, the operating environment (e.g., open air, vacuum, a specific gas) can chemically react with the element material, dramatically affecting its performance and lifespan. You must specify an element material suitable for your specific conditions.

How to Specify Your Heating Element Correctly

Use this framework to ensure you provide all the necessary information, whether you are replacing an old part or designing a new system.

- If you are replacing an existing element: Your primary goal is to find an exact match. Measure the

Le,Lu,a, and diameters precisely, and copy the voltage and wattage ratings printed on the old element or listed in the equipment manual. - If you are designing a new system: Start with your thermal requirements. First, determine the necessary wattage and operating temperature, then design the physical dimensions (

Le,Lu,a) to fit your chamber while maintaining a safe watt density for the chosen element material. - If you are ever unsure: Always consult the original equipment manufacturer or a specialized heating element supplier. Providing them with all the dimensions, performance ratings, and application details is the safest path forward.

A complete and accurate specification is the foundation for a safe, efficient, and long-lasting thermal system.

Summary Table:

| Dimension/Factor | Description | Importance |

|---|---|---|

| Heating Zone Length (Le) | Length of the active heating part | Determines surface area for heat transfer |

| Cold Zone Length (Lu) | Length of unheated terminal sections | Protects electrical connections from heat |

| Shank Distance (a) | Center-to-center distance between legs | Ensures proper fit in mounting holes |

| Heating Zone Diameter (d) | Diameter of the heating section | Affects surface area and watt density |

| Cold Zone Diameter (c) | Diameter of the cold sections | May differ for structural support |

| Watt Density | Power divided by surface area | Critical for longevity and performance |

| Voltage and Wattage | Electrical specifications | Must match power supply and thermal needs |

| Operating Temperature | Maximum temperature requirement | Dictates material selection (e.g., Nichrome) |

| Operating Environment | Conditions like air, vacuum, or gas | Influences material choice and lifespan |

Need a custom U-shaped heating element for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for optimal fit, performance, and longevity. Contact us today to discuss your specific needs and enhance your thermal system's efficiency!

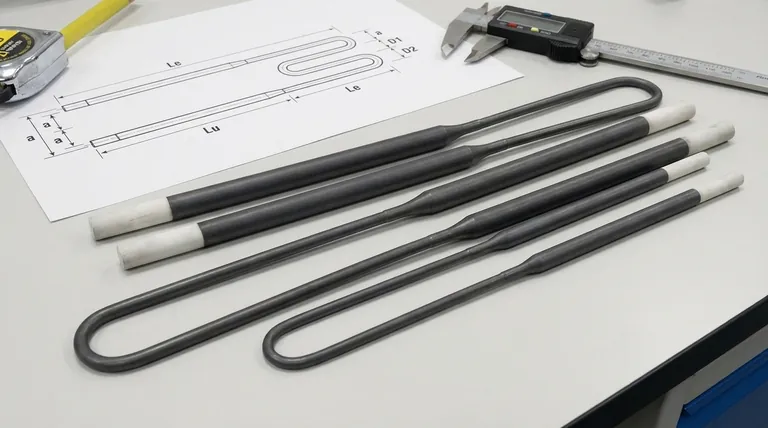

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs