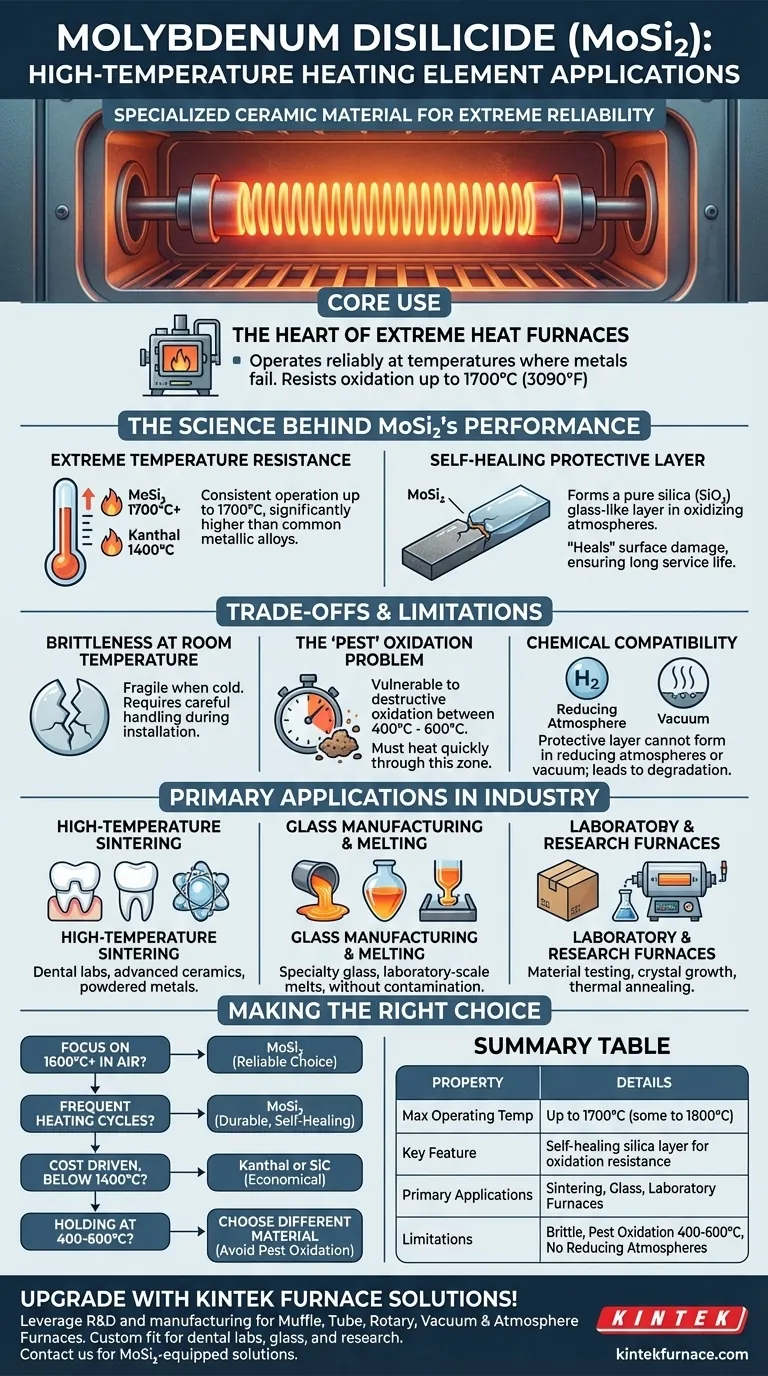

At its core, Molybdenum Disilicide (MoSi₂) is a specialized ceramic material used almost exclusively for high-performance electric heating elements. Its primary application is in industrial and laboratory furnaces that must operate reliably at extreme temperatures where conventional metallic elements would fail.

The central challenge in high-temperature heating is finding a material that can generate intense heat without destroying itself through oxidation. MoSi₂ solves this by not only resisting heat up to 1700°C but by also forming its own self-healing glass-like layer that protects it from atmospheric damage.

The Science Behind MoSi₂'s Performance

To understand why MoSi₂ is chosen for such demanding roles, we need to look at its unique chemical and physical properties under heat.

Extreme Temperature Resistance

MoSi₂ heating elements can operate consistently at temperatures up to 1700°C (3090°F), with some variants reaching 1800°C. This is significantly higher than most common metallic heating alloys like Kanthal (FeCrAl), which typically top out around 1400°C.

The Self-Healing Protective Layer

This is the most critical property of Molybdenum Disilicide. When heated in an oxygen-containing atmosphere, the silicon within the MoSi₂ reacts with oxygen to form a thin, non-conductive, and highly stable layer of pure silica (SiO₂), which is essentially glass.

This silica layer acts as a protective barrier, preventing the underlying material from further oxidation. If a crack or spall develops on the element's surface during operation, the newly exposed MoSi₂ immediately forms a new silica layer, effectively "healing" the damage and ensuring a long service life.

Stability in Oxidizing Atmospheres

Because of this self-healing silica layer, MoSi₂ elements are designed specifically for use in air or other oxidizing environments. Unlike materials that corrode or degrade in the presence of oxygen at high temperatures, MoSi₂ thrives, constantly maintaining its protective coating.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the specific limitations of MoSi₂ is crucial for its successful application and for preventing premature failure.

Brittleness at Room Temperature

Like many advanced ceramics, MoSi₂ is very brittle and fragile at lower temperatures. It is susceptible to damage from mechanical shock or impact during shipping, installation, and initial furnace startup. Care must be taken when handling the elements.

The "Pest" Oxidation Problem

MoSi₂ has a significant vulnerability at intermediate temperatures, typically between 400°C and 600°C. In this range, it can undergo a destructive form of accelerated oxidation, known as "pest oxidation," which can cause the material to disintegrate into powder.

For this reason, MoSi₂ elements must be heated quickly through this temperature range. They are not suitable for applications that require dwelling for long periods within this 400-600°C zone.

Chemical Compatibility

The protective silica layer can react with certain atmospheres or materials. MoSi₂ elements are not recommended for use in reducing atmospheres (like hydrogen) or in a vacuum, as the protective layer cannot form and the material may degrade.

Primary Applications in Industry

Given its unique profile of properties and limitations, MoSi₂ has found its niche in several key high-temperature industries.

High-Temperature Sintering Furnaces

These elements are essential in dental laboratories for sintering zirconia crowns and bridges, a process that requires clean, precise heat up to 1600°C. They are also used for sintering other advanced ceramics and powdered metals.

Glass Manufacturing and Melting

The very high temperatures required for melting and processing specialty glass make MoSi₂ an ideal choice. The elements can be used in glass feeders, forehearths, and laboratory-scale melt furnaces without contaminating the glass.

Laboratory and Research Furnaces

Research and development labs rely on box and tube furnaces for material testing, crystal growth, and thermal annealing. MoSi₂ elements provide the clean, stable, and high-temperature environment required for this work.

Making the Right Choice for Your Application

Selecting the correct heating element requires matching the material's properties to your specific operational needs.

- If your primary focus is operating above 1600°C in an air atmosphere: MoSi₂ is often the definitive and most reliable choice available.

- If your application involves frequent heating and cooling cycles: The self-healing nature of the silica layer makes MoSi₂ exceptionally durable and long-lasting.

- If cost is the main driver and your process stays below 1400°C: Economical alternatives like Kanthal (FeCrAl) or Silicon Carbide (SiC) may be more suitable.

- If your process requires holding temperatures between 400°C and 600°C: MoSi₂ is unsuitable due to the risk of pest oxidation, and a different material must be chosen.

Understanding both the remarkable strengths and critical weaknesses of Molybdenum Disilicide empowers you to select the right material for your high-temperature challenge.

Summary Table:

| Property | Details |

|---|---|

| Max Operating Temperature | Up to 1700°C (some variants to 1800°C) |

| Key Feature | Self-healing silica layer for oxidation resistance |

| Primary Applications | High-temperature sintering, glass manufacturing, laboratory furnaces |

| Limitations | Brittle at room temperature, pest oxidation at 400-600°C, not for reducing atmospheres |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for industries like dental labs, glass manufacturing, and research facilities. Our deep customization capabilities ensure precise fit for your unique experimental needs. Contact us today to discuss how our MoSi₂-equipped furnaces can enhance reliability and efficiency in your operations!

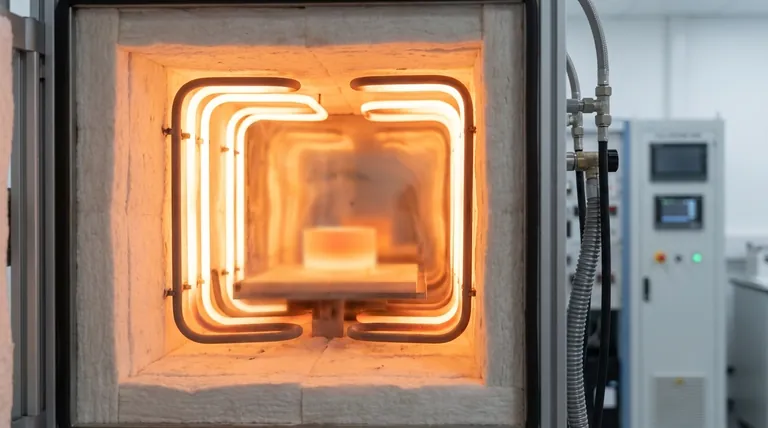

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions