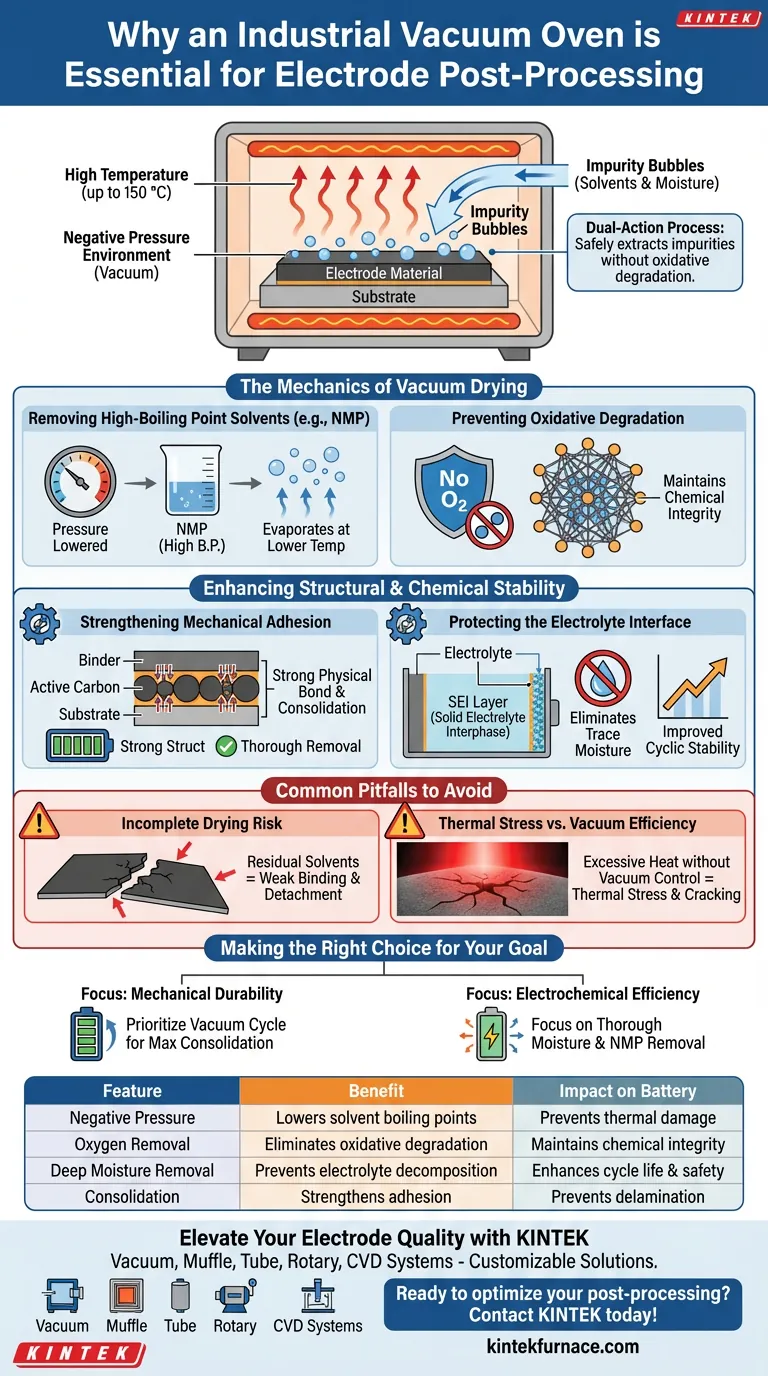

An industrial vacuum oven is essential for post-processing electrode materials because it combines high temperatures (up to 150 °C) with a negative pressure environment to safely extract stubborn impurities. This dual-action process removes residual high-boiling point solvents and trace moisture without triggering oxidative degradation, ensuring the electrode remains chemically pure and mechanically robust.

Core Takeaway The vacuum oven serves as a critical stabilization step, utilizing low pressure to lower solvent boiling points and eliminate oxygen. This prevents material degradation during drying while securing the physical bond between the active material and the substrate, directly impacting the battery's long-term cycle life and safety.

The Mechanics of Vacuum Drying

Removing High-Boiling Point Solvents

Electrode slurries often contain solvents with high boiling points, such as NMP (N-methyl-2-pyrrolidone), which are difficult to remove under standard atmospheric conditions.

The vacuum oven creates a negative pressure environment. This lowers the boiling point of these solvents, allowing them to evaporate thoroughly without requiring excessive temperatures that could damage the active materials.

Preventing Oxidative Degradation

Applying high heat to electrode materials in the presence of air typically accelerates oxidation. This chemical change can degrade the active components before the battery is even assembled.

By operating in a vacuum, the oven removes oxygen from the chamber. This ensures that the material can be dried at the necessary 120–150 °C range while maintaining its chemical integrity.

Enhancing Structural and Chemical Stability

Strengthening Mechanical Adhesion

The drying process is not just about removal; it is about consolidation. The vacuum process ensures a strong physical bond forms between the binder, active carbon, and the substrate (current collector).

This enhanced adhesion is critical for mechanical stability. It prevents the active material from detaching or delaminating during subsequent manufacturing steps, such as fluid flushing, or during the expansion and contraction of battery cycling.

Protecting the Electrolyte Interface

Residual moisture is a primary cause of electrolyte decomposition and side reactions during charge/discharge cycles.

By thoroughly eliminating trace moisture, vacuum drying enables the formation of a stable Solid Electrolyte Interphase (SEI) layer. This directly improves the battery's Coulombic efficiency and ensures long-term cyclic stability.

Common Pitfalls to Avoid

The Risk of Incomplete Drying

If the vacuum level or duration is insufficient, trace solvents remains deep within the electrode structure.

This residual solvent weakens the binding network, leading to poor adhesion and eventual material detachment under mechanical stress.

Thermal Stress vs. Vacuum Efficiency

Relying solely on temperature to speed up the process is a mistake.

Excessive heat without adequate vacuum control can cause thermal stress or cracking in the electrode coating. The process relies on the balance of pressure and heat, not heat alone.

Making the Right Choice for Your Goal

While the vacuum oven is a standard requirement, how you optimize the parameters depends on your specific performance targets.

- If your primary focus is Mechanical Durability: Prioritize the vacuum cycle to maximize the consolidation of the binder and active carbon, ensuring the material can withstand physical handling and flushing.

- If your primary focus is Electrochemical Efficiency: Focus on the thorough removal of trace moisture and NMP to prevent side reactions and ensure a stable SEI layer formation.

Ultimately, the industrial vacuum oven is not just a drying tool; it is a prerequisite for creating a chemically stable and mechanically sound electrode.

Summary Table:

| Feature | Benefit for Electrode Processing | Impact on Battery |

|---|---|---|

| Negative Pressure | Lowers boiling points of solvents like NMP | Prevents thermal damage to active materials |

| Oxygen Removal | Eliminates oxidative degradation at high temps | Maintains chemical integrity and purity |

| Deep Moisture Removal | Prevents electrolyte decomposition | Enhances cycle life and safety (SEI stability) |

| Consolidation | Strengthens binder-to-substrate adhesion | Prevents delamination during cycling |

Elevate Your Electrode Quality with KINTEK

Maximize your battery’s cycle life and mechanical durability with precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet your specific lab or industrial requirements. Our vacuum ovens provide the precise pressure and temperature control necessary to eliminate trace impurities without compromising material integrity.

Ready to optimize your post-processing workflow? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Belén Lobato, Ana Arenillas. Designing and Optimizing Electrode Materials for Energy Harvesting in CAPMIX Cells. DOI: 10.3390/nano14242031

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What is the function of a laboratory vacuum drying oven in W-Ni2P@NiFe LDH/NF preparation? Optimize Electrocatalysts

- What are the challenges of maintaining a high vacuum in furnaces? Overcome Key Hurdles for Optimal Performance

- What heat treatment processes can a vacuum furnace perform? Achieve Superior Control and Clean Results

- What is the role of a vacuum drying oven in processing HAp powder? Optimize Your Slurry for High-Density Ceramics

- Why is a vacuum oven utilized for drying NaFePO4 gel? Prevent Oxidation and Ensure Chemical Homogeneity

- What are the main advantages of a vacuum furnace compared to an ordinary heat treatment furnace? Achieve Pristine Surfaces and Precise Control

- What types of power supplies are used for heating elements in vertical vacuum furnaces? SCR vs VRT for Precision Heating

- Why does the simulation of magnesium alloy distillation require high precision? Master Vacuum for Purity