At its core, a vacuum furnace offers two transformative advantages over a conventional heat treatment furnace: it creates a chemically pure environment and provides unparalleled process control. By removing the atmosphere, it completely prevents surface oxidation and decarburization, resulting in a pristine final part that requires no secondary cleaning. This controlled environment also allows for extremely precise, repeatable, and automated thermal cycles that are impossible to achieve in a standard atmospheric furnace.

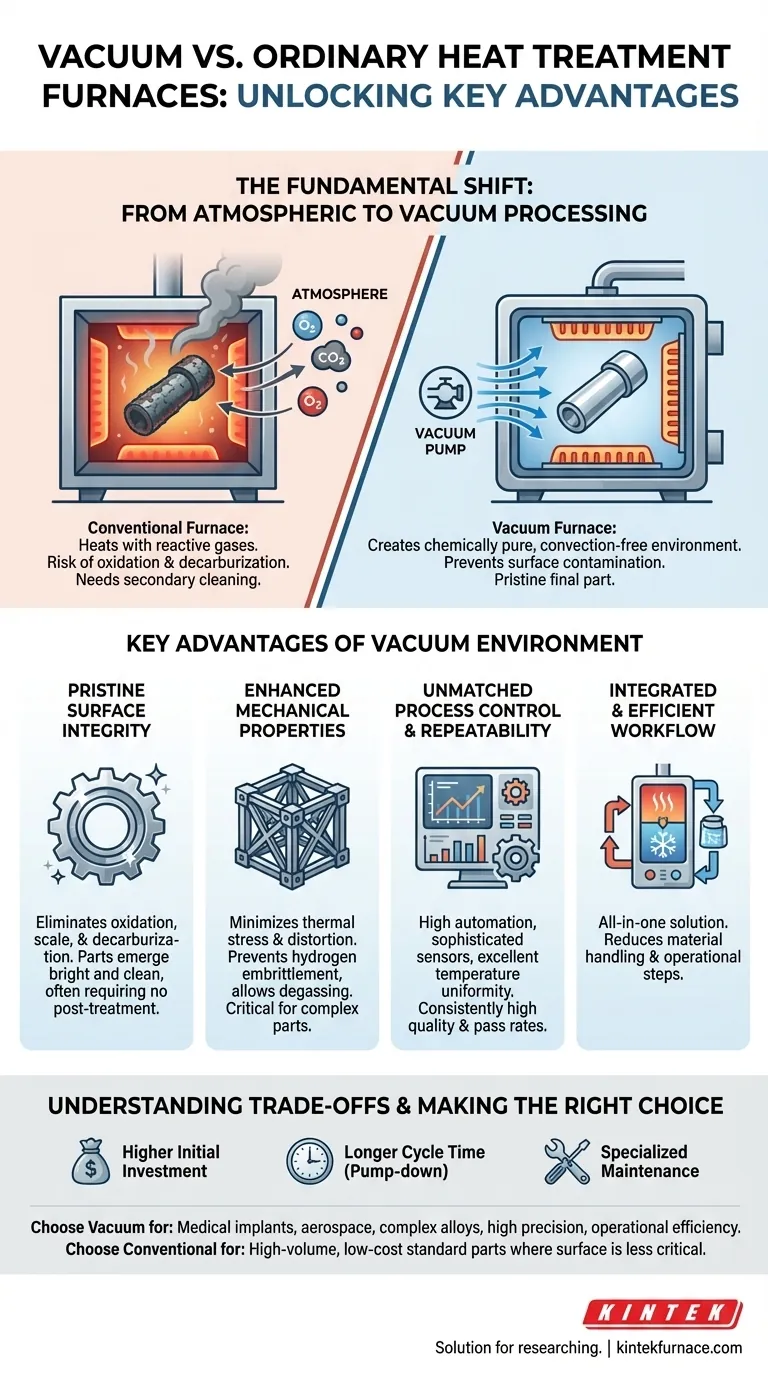

While a conventional furnace heats material in the presence of reactive gases, a vacuum furnace first removes the atmosphere entirely. This fundamental difference is the source of all its key benefits: superior surface quality, enhanced material properties, and repeatable, automated process control.

The Fundamental Shift: From Atmospheric to Vacuum Processing

The primary distinction between these two technologies lies in the environment where the heating takes place. This single factor drives all subsequent differences in quality, efficiency, and capability.

How Conventional Furnaces Work

A conventional furnace heats parts in the presence of the surrounding atmosphere or a controlled gas mixture. At high temperatures, these gases, particularly oxygen, react with the metal's surface.

This leads to undesirable outcomes like oxidation (scaling) and decarburization (the loss of carbon from the surface of steel), which can degrade the part's appearance and mechanical properties.

The Vacuum Furnace Principle

A vacuum furnace is a sealed chamber where a powerful pump system removes the air before the heating cycle begins. This creates a convection-free environment with virtually no reactive molecules.

Heating is typically accomplished with resistive elements, and the lack of an atmosphere ensures that heat is transferred primarily through radiation. This provides clean, uniform heating without the risk of surface contamination.

Key Advantages of a Controlled Vacuum Environment

The absence of a reactive atmosphere unlocks several significant performance and quality benefits that define vacuum heat treatment.

Pristine Surface Integrity

By eliminating oxygen and other reactive gases, a vacuum furnace delivers parts with a bright, clean surface straight out of the furnace.

This completely prevents the formation of scale and the creation of a decarburized "metamorphic layer." The result is a finished part that often requires no costly and time-consuming post-treatment grinding or cleaning.

Enhanced Mechanical Properties

The precise control over heating and cooling rates minimizes thermal stress and distortion, which is critical for complex or thin-walled components.

Furthermore, the vacuum environment is essential for preventing hydrogen embrittlement in sensitive materials and allows for degassing and purification of the material itself during the cycle.

Unmatched Process Control and Repeatability

Vacuum furnaces operate with a high degree of automation and electromechanical integration. Sophisticated sensors and computer controls ensure exceptional temperature uniformity and accuracy.

This allows for the execution of complex, multi-stage thermal profiles with extreme stability and repeatability. The result is a very high product pass rate and consistent quality from batch to batch.

Integrated and Efficient Workflow

Many vacuum furnaces are an all-in-one solution. They can perform heating, quenching (using high-pressure inert gas), and cooling all within the same sealed chamber.

This integrated process is more efficient and reduces material handling compared to a conventional workflow, which often requires moving hot parts between a separate furnace and a quench tank.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for every application. Acknowledging their limitations is key to making an informed decision.

Initial Investment Cost

Vacuum furnaces are technologically complex systems. The robust chamber, powerful vacuum pumps, and sophisticated control systems typically result in a higher upfront capital investment compared to simpler atmospheric furnaces.

Cycle Time Considerations

The process of pumping the chamber down to the required vacuum level adds time to the beginning of every cycle. For high-volume, simple heat treatments, this pump-down time can make the total cycle longer than in a continuous-belt atmospheric furnace.

Maintenance and Operational Complexity

The high-tech components of a vacuum system, including pumps, seals, and instrumentation, require specialized maintenance knowledge. Troubleshooting and upkeep are generally more demanding than for a conventional furnace.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on the specific quality requirements, materials, and production goals of your project.

- If your primary focus is surface finish and material purity (e.g., medical implants, aerospace components): The complete elimination of oxidation and contamination makes a vacuum furnace the definitive choice.

- If your primary focus is processing complex alloys or achieving specific microstructures: The precise, automated, and repeatable temperature control of a vacuum furnace is essential for meeting tight specifications.

- If your primary focus is operational efficiency and reducing post-processing: The integrated "all-in-one" nature of a vacuum furnace and its ability to produce clean parts can significantly reduce labor and secondary operations.

- If your primary focus is high-volume, low-cost treatment of standard parts where surface oxidation is acceptable: A conventional atmosphere furnace may offer a more cost-effective solution with a lower initial investment.

By understanding these core principles, you can confidently determine whether a vacuum furnace is not just a different tool, but the right solution for your specific engineering goals.

Summary Table:

| Advantage | Description |

|---|---|

| Pristine Surface Integrity | Eliminates oxidation and decarburization, producing clean parts without secondary cleaning. |

| Enhanced Mechanical Properties | Reduces thermal stress, distortion, and prevents hydrogen embrittlement for better material performance. |

| Unmatched Process Control | Provides precise, automated, and repeatable thermal cycles with high temperature uniformity. |

| Integrated Workflow | All-in-one solution for heating, quenching, and cooling, improving efficiency and reducing handling. |

Ready to elevate your heat treatment processes with advanced vacuum furnace solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact us today to discuss how our vacuum furnaces can deliver pristine surfaces, enhanced properties, and unmatched control for your applications—get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion