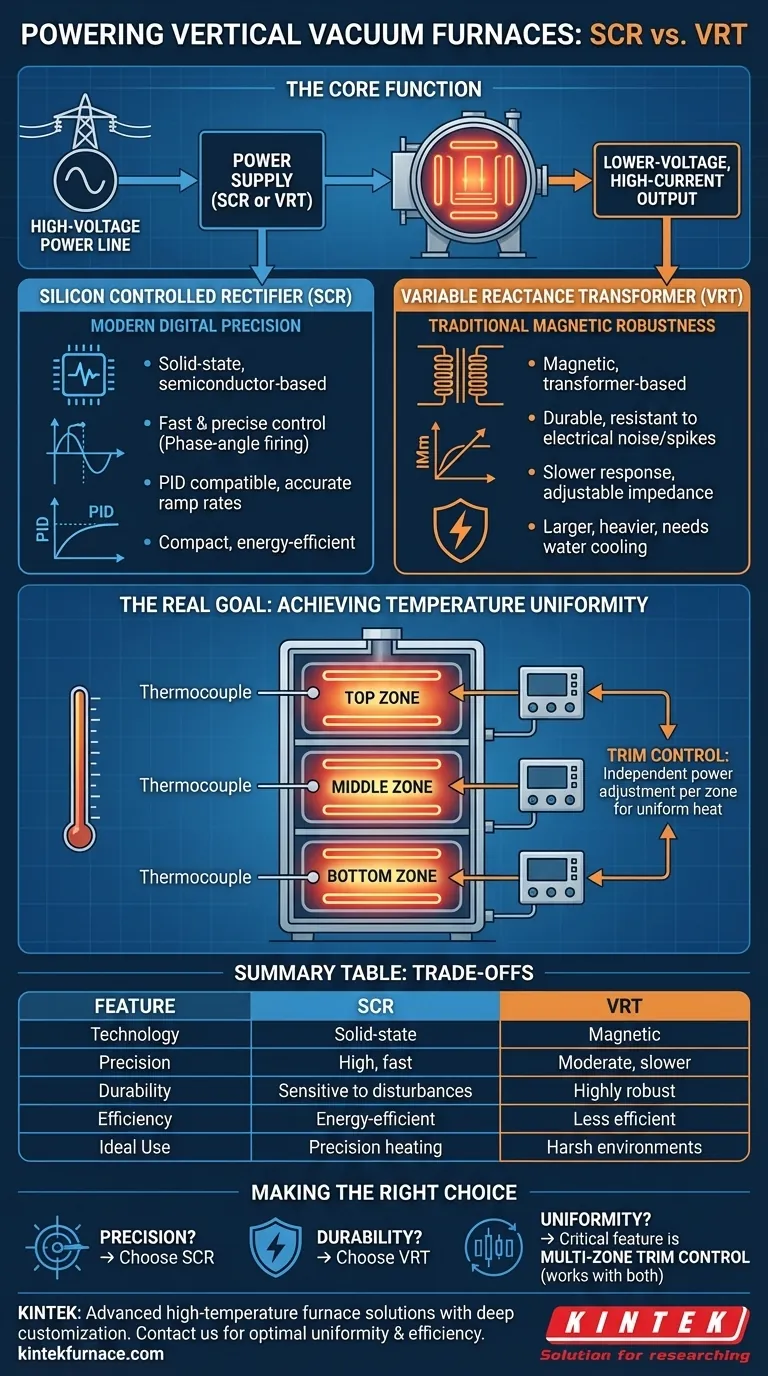

In vertical vacuum furnaces, power is delivered to the heating elements by one of two primary technologies: a solid-state Silicon Controlled Rectifier (SCR) or a magnetic Variable Reactance Transformer (VRT). Both systems are designed to precisely manage the immense power required to achieve and maintain high temperatures, with integrated trim controls to ensure temperature uniformity throughout the heating zone.

The choice between an SCR and a VRT is a decision between modern digital precision and traditional magnetic robustness. However, the true key to effective heating is not the power source itself, but how it is used to manage multiple heating zones for absolute temperature uniformity.

The Core Function: Powering the Heating Elements

A vacuum furnace power supply has one fundamental job: to convert high-voltage line power into a controlled, lower-voltage, high-current output. This current flows through resistive heating elements, generating the heat required for the process.

Silicon Controlled Rectifiers (SCR)

The SCR is the modern, industry-standard power controller for vacuum furnaces. It is a solid-state, semiconductor-based device that offers extremely fast and precise control.

SCRs work by "phase-angle firing," where they switch on and off rapidly within each AC power cycle. By adjusting when the switch occurs, the SCR can precisely chop the AC waveform, controlling the exact amount of energy delivered to the heating elements.

This rapid response is critical for modern PID temperature controllers, allowing for tight stability and accurate ramp rates. Most new furnaces are specified with SCR power supplies due to their efficiency and control fidelity.

Variable Reactance Transformers (VRT)

The VRT is an older, magnetic-based technology that is exceptionally durable. It is essentially a transformer with an adjustable impedance.

A separate DC control winding is used to change the magnetic saturation of the transformer's iron core. This change in saturation alters the transformer's reactance, which in turn regulates the output voltage and current sent to the heating elements.

While heavier, larger, and slower to respond than SCRs, VRTs are incredibly robust and highly resistant to poor power quality, electrical noise, and short circuits. They almost always require water cooling and are often found on older furnaces, though they remain a viable option for harsh industrial environments.

The Real Goal: Achieving Temperature Uniformity

Simply delivering power is not enough. The ultimate goal of the power supply and control system is to ensure the entire workload reaches and holds a uniform temperature. This is accomplished through zoned heating.

Understanding Heating Zones

A furnace's hot zone is not heated by a single circuit. It is divided into multiple independent heating zones, typically a top, middle, and bottom zone in a vertical furnace.

Each zone has its own set of heating elements and is monitored by its own thermocouple. This division is necessary to compensate for natural heat loss and convection.

The Role of Trim Control

The power supply system provides a separate, independently adjustable power output for each heating zone. This is known as trim control.

The furnace's temperature controller continuously compares the temperature of each zone to the desired setpoint. It then instructs the power supply's trim circuits to increase or decrease power to individual zones, balancing the heat to achieve uniformity across the entire workload.

Understanding the Trade-offs: SCR vs. VRT

Choosing between these technologies involves balancing precision against durability.

SCR: Precision and Efficiency

An SCR-based system is the default choice for most applications today. Its primary advantages are speed and precision, which enable advanced temperature control algorithms.

They are also more compact, energy-efficient, and can be mounted directly on the furnace frame to conserve floor space. Their main drawback is a higher sensitivity to power line disturbances and electrical noise compared to a VRT.

VRT: Unmatched Robustness

A VRT's strength is its sheer toughness. It acts as a buffer between the power line and the furnace, absorbing voltage spikes and tolerating poor power quality that could damage an SCR.

However, VRT systems are significantly larger, heavier, and less energy-efficient. Their slower response time may not be suitable for processes requiring extremely rapid thermal cycling, and the need for water cooling adds a layer of maintenance complexity.

Making the Right Choice for Your Process

Your process requirements will guide the best choice of power supply technology, but the principle of zoned control is universal.

- If your primary focus is state-of-the-art precision: An SCR power supply is the standard choice, offering the fast response needed for advanced, uniform heat treatment.

- If your primary focus is extreme durability in a harsh electrical environment: A VRT remains a highly reliable option, sacrificing some speed for unparalleled electrical ruggedness.

- If your primary focus is temperature uniformity: The critical feature is a multi-zone trim control system, which can be implemented with either an SCR or a VRT power supply.

Ultimately, a properly engineered power system empowers you to control the furnace environment with absolute confidence.

Summary Table:

| Feature | Silicon Controlled Rectifier (SCR) | Variable Reactance Transformer (VRT) |

|---|---|---|

| Technology | Solid-state, semiconductor-based | Magnetic, transformer-based |

| Control Precision | High, with fast response | Moderate, slower response |

| Durability | Sensitive to power disturbances | Highly robust, resistant to noise |

| Efficiency | Energy-efficient, compact | Less efficient, larger and heavier |

| Ideal Use Cases | Precision heating, modern applications | Harsh environments, older systems |

Need expert guidance on power supplies for your vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for optimal temperature uniformity and efficiency. Contact us today to discuss how our tailored solutions can enhance your laboratory's performance!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing