The primary role of a vacuum drying oven in processing hydroxyapatite (HAp) powder is to rigorously remove adsorbed water and volatile impurities prior to mixing. By utilizing a negative pressure environment, the oven allows moisture to evaporate at lower temperatures, preventing the thermal damage or structural alteration that might occur with standard high-heat drying.

The effective removal of moisture is not just a cleaning step; it is the fundamental prerequisite for preventing particle agglomeration, ensuring the HAp powder can achieve the high solid content and low viscosity necessary for high-performance ceramic slurries.

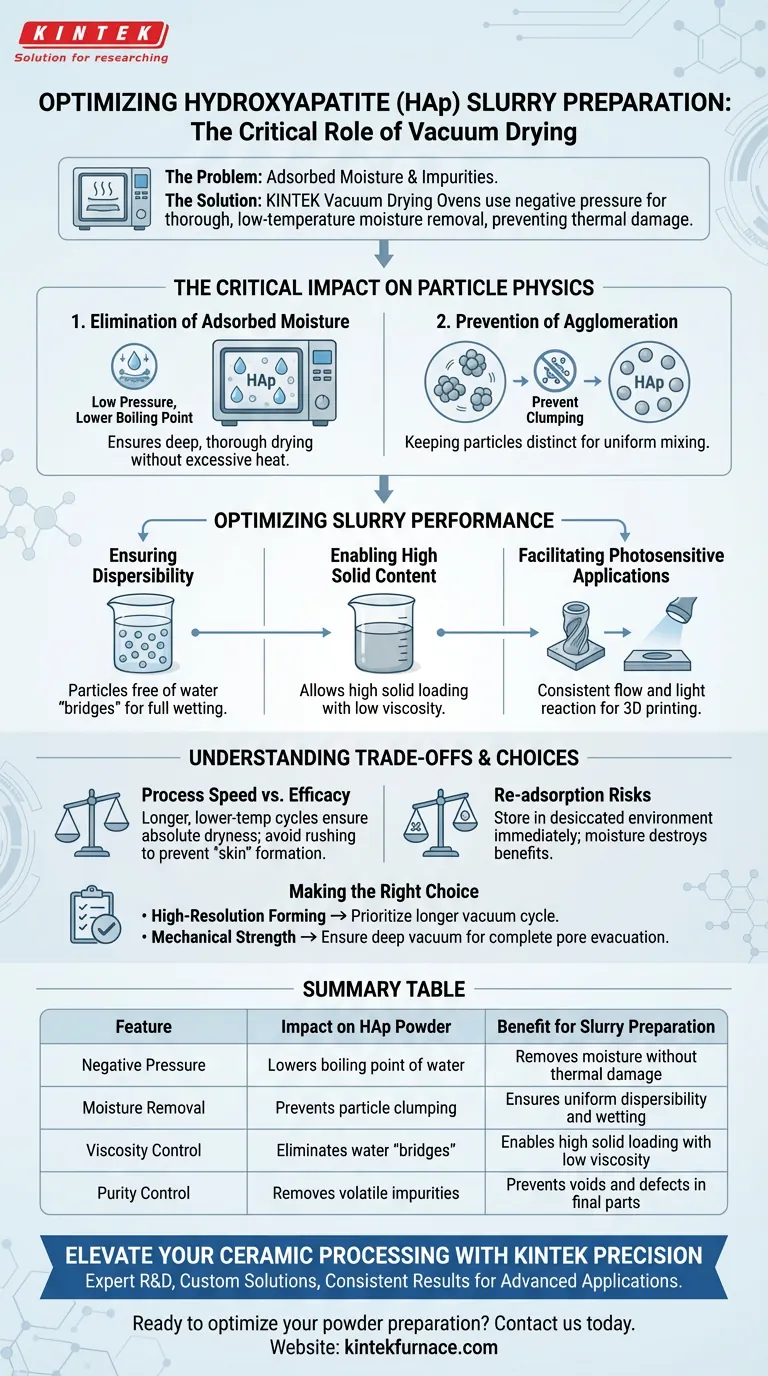

The Critical Impact on Particle Physics

Elimination of Adsorbed Moisture

Hydroxyapatite powders often retain moisture within their porous structures or on their surfaces. The vacuum drying oven creates a low-pressure environment that significantly lowers the boiling point of water. This ensures deep, thorough drying of the powder without requiring excessive heat, which preserves the material's fundamental properties.

Prevention of Agglomeration

Moisture acts as a binding agent that causes fine powders to stick together. By removing this moisture, the vacuum process prevents nano-scale and micro-scale particles from clumping. Keeping particles distinct and separate is essential for achieving a uniform mixture in later stages.

optimizing Slurry Performance

Ensuring Dispersibility

For HAp powder to function correctly in a slurry, it must disperse evenly throughout the liquid medium. Vacuum drying ensures the individual particles are free of water "bridges," allowing them to be fully wetted and dispersed by the slurry's solvent and resin components.

Enabling High Solid Content

To produce high-density ceramic parts, the slurry requires a high ratio of solid powder to liquid. Residual moisture artificially increases viscosity, making high loading impossible. Vacuum drying allows for high solid content formulations that maintain low viscosity and excellent flow properties.

Facilitating Photosensitive Applications

In the specific context of photosensitive ceramic slurries (often used in 3D printing or lithography), consistency is paramount. The vacuum drying step removes variables caused by humidity, ensuring the slurry flows predictably and reacts consistently to light curing during the forming process.

Understanding the Trade-offs

Process Speed vs. Efficacy

While vacuum drying is highly effective, it is generally a slower process than standard convection drying. Users must balance the duration of the cycle against the strict moisture-content requirements of their specific application. Rushing this step often leads to "skin" formation where the surface is dry, but internal moisture remains.

Re-adsorption Risks

HAp powder can be hygroscopic (water-absorbing). A common pitfall is drying the powder effectively but exposing it to humid air immediately afterward. The benefits of vacuum drying are negated instantly if the powder is not stored in a desiccated environment or processed immediately after removal from the oven.

Making the Right Choice for Your Goal

To maximize the effectiveness of your slurry preparation, consider your specific manufacturing targets:

- If your primary focus is high-resolution forming: Prioritize a longer, lower-temperature vacuum cycle to ensure absolute dryness, which guarantees the low viscosity needed for detailed photosensitive applications.

- If your primary focus is mechanical strength: Ensure the vacuum level is deep enough to evacuate pores completely, as any residual moisture can create voids or defects in the final sintered ceramic part.

Success in ceramic processing relies not just on the quality of the powder, but on the absolute purity of its preparation environment.

Summary Table:

| Feature | Impact on HAp Powder | Benefit for Slurry Preparation |

|---|---|---|

| Negative Pressure | Lowers boiling point of water | Removes moisture without thermal damage |

| Moisture Removal | Prevents particle clumping | Ensures uniform dispersibility and wetting |

| Viscosity Control | Eliminates water 'bridges' | Enables high solid loading with low viscosity |

| Purity Control | Removes volatile impurities | Prevents voids and defects in final sintered parts |

Elevate Your Ceramic Processing with KINTEK Precision

Don't let residual moisture compromise your material integrity. At KINTEK, we understand that high-performance hydroxyapatite applications require absolute purity and precise environmental control.

Backed by expert R&D and manufacturing, KINTEK offers advanced Vacuum Drying Ovens, along with Muffle, Tube, Rotary, and CVD systems—all customizable to meet your unique lab requirements. Whether you are developing 3D-printed photosensitive slurries or high-strength bio-ceramics, our equipment ensures consistent results and superior material properties.

Ready to optimize your powder preparation? Contact us today to find the perfect drying solution for your lab!

Visual Guide

References

- Ali Arab, Chunwei Zhang. Influence of Cell Geometry on the Mechanical and Failure Characteristics of 3D Voronoi Hydroxyapatite Through the Stereolithography Technique. DOI: 10.3390/ceramics8010004

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a precision vacuum system influence the sulfidation process of MoS2? Master Semiconductor Quality

- What is the main purpose of a vacuum sintering furnace? Fuse Powders into High-Performance Dense Parts

- How does Diamond Burnishing (DB) and Low-Temperature Gaseous Nitriding (LTGN) improve material output?

- What is the primary purpose of using industrial-grade stainless steel pressure vessels? Optimize Wood Modification

- What is the classification of a vacuum furnace? Match Performance, Process & Temperature to Your Needs

- What are the core advantages of using a Spark Plasma Sintering (SPS) system? Unlock Peak Ceramic Performance

- What are the key characteristics of vacuum hardening? Achieve Clean, Precise Metal Hardening for Superior Components

- How does a vacuum furnace ensure high-quality output? Achieve Superior Purity and Performance for Your Materials