An atmosphere-controlled tube furnace is the defining tool for converting Metal-Organic Frameworks (MOFs) into high-performance functional materials. It allows for high-temperature pyrolysis under specific inert environments, such as nitrogen or argon, to fundamentally alter the material's chemical structure without destroying it.

The Core Insight: The furnace allows for the simultaneous conversion of organic ligands into a conductive carbon matrix and metal ions into active nanoparticles. Without this controlled atmosphere, the organic structure would simply burn away, leaving behind low-performance, insulating bulk oxides.

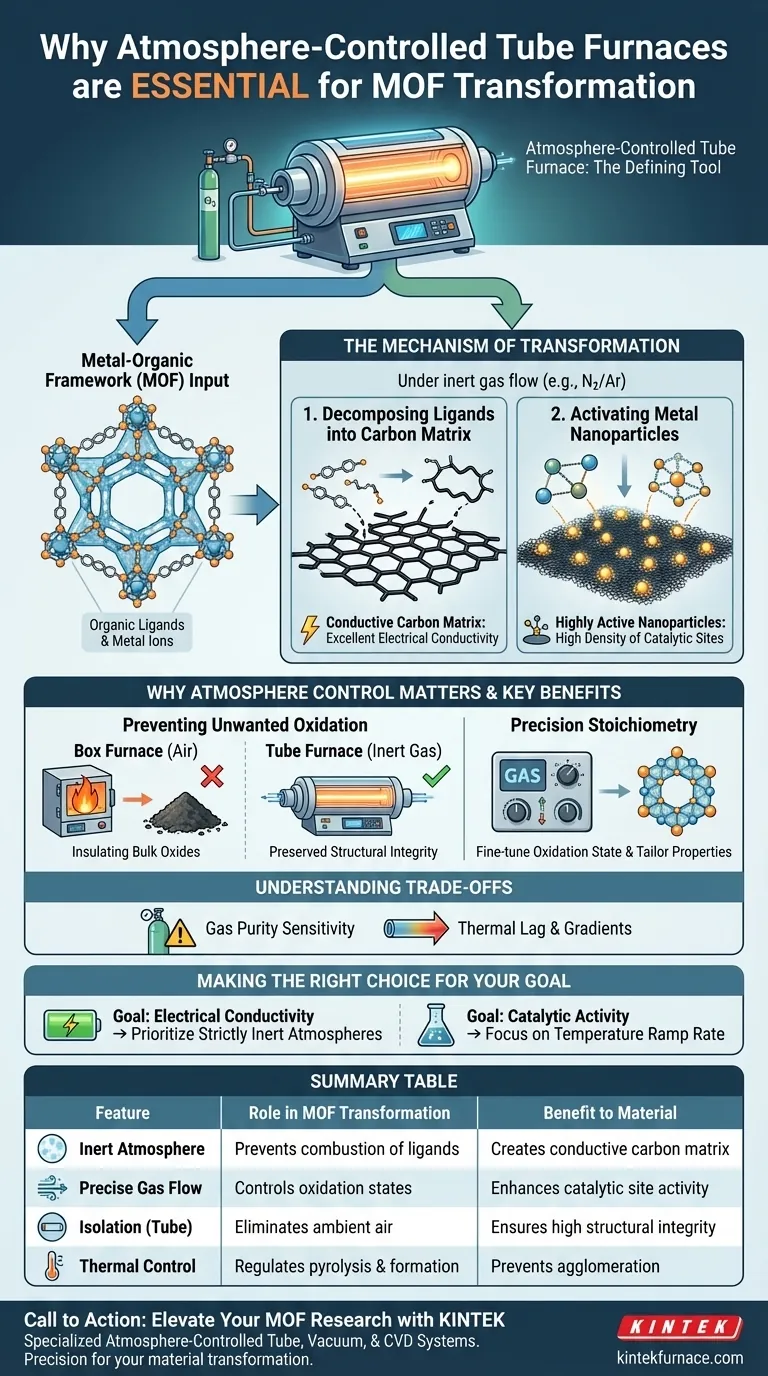

The Mechanism of Transformation

To understand why this equipment is essential, you must look at the chemical changes occurring within the MOF structure during heating.

Decomposing Ligands into Carbon

The primary function of the furnace is to decompose the organic ligands found within the MOF. In an inert atmosphere, these organics do not burn off; instead, they transform into a conductive carbon matrix.

This carbon backbone is critical for applications like sensors. It ensures the final material has excellent electrical conductivity, which is impossible to achieve if the ligands are fully oxidized in air.

Activating Metal Nanoparticles

Simultaneously, the furnace environment manipulates the metal ions present in the MOF. Through controlled reduction or oxidation, these ions are converted into highly active nanoparticles.

These nanoparticles become the active catalytic sites of the material. The process ensures a high density of these sites, directly improving the material's sensitivity and reactivity.

Why Atmosphere Control Matters

The "tube" design of the furnace is not just about heating; it is about isolation and gas flow management.

Preventing Unwanted Oxidation

Standard box furnaces often allow ambient air to interact with the sample. If a MOF is heated in air, the organic linkers combust completely, destroying the carbon structure.

The atmosphere-controlled furnace prevents this unnecessary oxidation. By maintaining a positive pressure of inert gas, it preserves the structural integrity required for high-performance sensor materials.

Precision Stoichiometry

While the primary goal with MOFs is often carbonization, the furnace also offers the flexibility to fine-tune oxygen levels if necessary.

Just as researchers regulate oxygen flow to optimize superconductors, you can adjust the gas environment to control the exact oxidation state of the metal. This precision allows you to tailor the material's properties—from conductivity to catalytic activity—at a microscopic level.

Understanding the Trade-offs

While an atmosphere-controlled tube furnace is powerful, it introduces specific variables that must be managed to avoid failure.

Gas Purity Sensitivity

The quality of your output is entirely dependent on the purity of your gas source. Even trace amounts of oxygen in a "nitrogen" environment can degrade the conductivity of the carbon matrix.

Thermal Lag and Gradients

Tube furnaces can experience thermal gradients along the length of the tube. Placing the MOF sample outside the constant temperature zone can lead to incomplete pyrolysis or inconsistent nanoparticle formation.

Making the Right Choice for Your Goal

The way you utilize the furnace should be dictated by the specific properties you need in your final material.

- If your primary focus is Electrical Conductivity: Prioritize strictly inert atmospheres (Ar or N2) to maximize the formation of the graphitic carbon matrix and prevent ligand combustion.

- If your primary focus is Catalytic Activity: Focus on the temperature ramp rate to control the size of the metal nanoparticles; rapid heating may cause agglomeration, reducing the density of active sites.

Control the atmosphere, and you control the material's destiny.

Summary Table:

| Feature | Role in MOF Transformation | Benefit to Material |

|---|---|---|

| Inert Atmosphere | Prevents combustion of organic ligands | Creates a conductive carbon matrix |

| Precise Gas Flow | Controls oxidation states of metal ions | Enhances catalytic site activity |

| Isolation (Tube) | Eliminates ambient air contamination | Ensures high structural integrity |

| Thermal Control | Regulates pyrolysis and nanoparticle formation | Prevents agglomeration for better sensitivity |

Elevate Your MOF Research with KINTEK

Precision is the difference between a failed sample and a high-performance functional material. Backed by expert R&D and manufacturing, KINTEK offers specialized Atmosphere-Controlled Tube, Vacuum, and CVD systems designed to give you absolute mastery over your pyrolysis environment.

Whether you are developing sensors, catalysts, or energy storage solutions, our customizable high-temperature furnaces ensure the exact stoichiometry and structural integrity your research demands.

Ready to optimize your material transformation? Contact KINTEK today for a customized solution.

Visual Guide

References

- Haibing Zhu, Zhanjun Yang. Non-Enzymatic Electrochemical Glucose Sensors Based on Metal Oxides and Sulfides: Recent Progress and Perspectives. DOI: 10.3390/chemosensors13010019

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the role of a tube furnace in the synthesis of porous nitrogen-doped carbon (NC) supports? Maximize Catalytic Performance

- What safety protection mechanisms are typically included in tube furnaces? Ensure Operator and Equipment Safety

- What is the function of a laboratory tube furnace in BiFeO3 nanopowder production? Master the Calcination Stage

- What is the primary purpose of using a high-temperature tube furnace? Master nZVI@BC Synthesis with Precision

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- How does a tube furnace achieve precise control over product components? Master Cottonseed Pyrolysis with Precision

- What are the key components of a drop tube furnace? Discover the 5 Essential Parts for High-Temperature Success

- What is the function of a tubular furnace in the sulfurization of Cu2SnS3? Master Semiconductor Phase Transformation