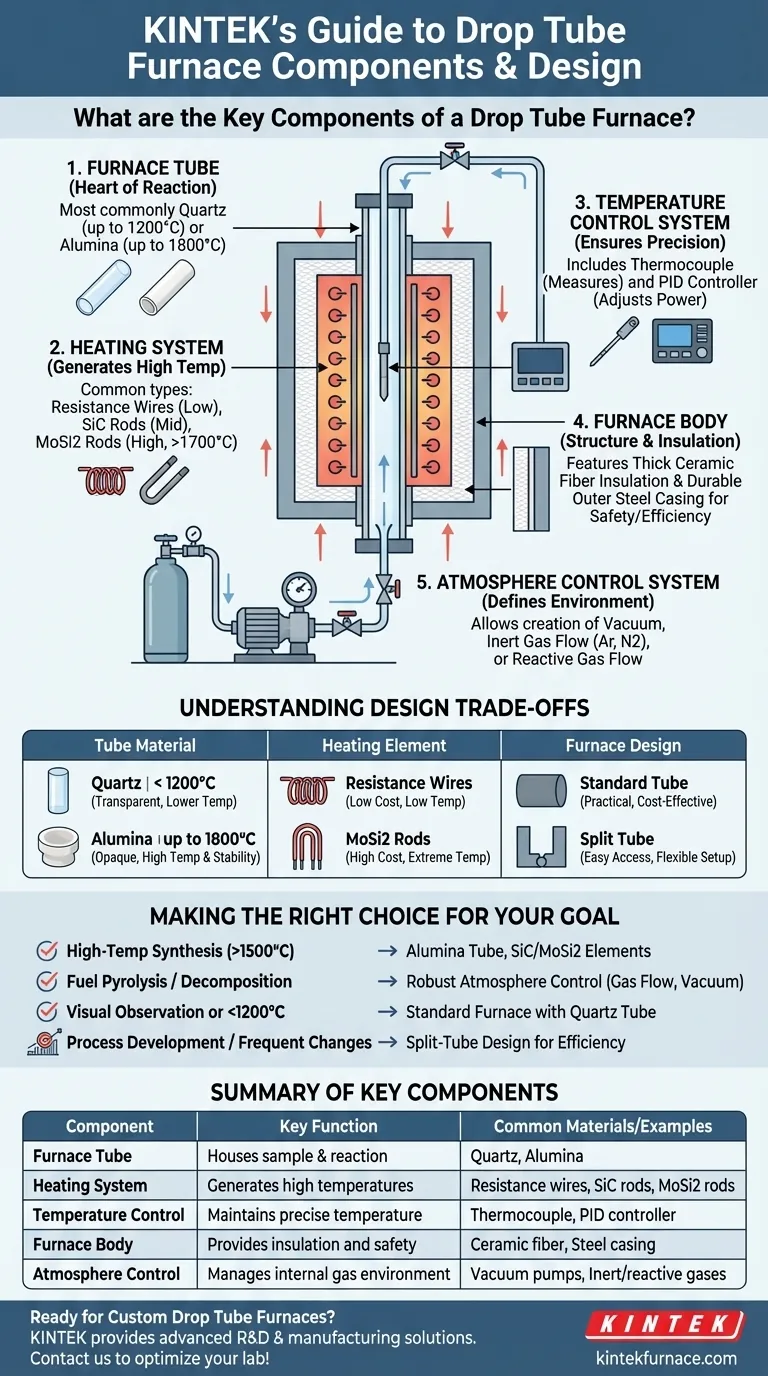

At its core, a drop tube furnace is a system of five primary components. These are the furnace tube that contains the sample, the heating elements that generate the high temperatures, a temperature control system for precision, the insulated furnace body for efficiency and safety, and an atmosphere control system to manage the internal environment. Each component is selected and integrated to achieve a specific range of operating conditions.

A drop tube furnace is not just a collection of parts, but a precisely engineered system. Understanding how each component contributes to the whole is the key to selecting the right instrument and designing successful high-temperature experiments.

Deconstructing the Furnace: Core Systems and Their Function

A tube furnace's performance is defined by the capabilities and interplay of its core systems. Each part has a distinct role in creating a controlled, high-temperature environment.

The Furnace Tube: The Heart of the Reaction

This is the central chamber where the sample is placed and the experiment occurs. The material of this tube is a critical choice.

Most commonly, tubes are made from quartz or high-purity alumina (also known as corundum). The choice dictates the furnace's maximum temperature and chemical compatibility.

The Heating System: Generating Extreme Temperatures

Heating elements are arranged around the outside of the furnace tube to provide uniform heat.

The type of element determines the furnace's temperature range. Common options include resistance wires for lower temperatures, silicon carbide (SiC) rods for mid-range temperatures, and silicon molybdenum (MoSi2) rods for the highest temperatures, often exceeding 1700°C.

The Temperature Control System: Ensuring Precision

This system ensures the furnace reaches and maintains the desired temperature with high accuracy.

It consists of a thermocouple, which measures the temperature inside the furnace, and a PID (Proportional-Integral-Derivative) controller. The controller reads the thermocouple's data and adjusts the power to the heating elements to maintain a stable setpoint.

The Furnace Body: Structure and Insulation

The furnace body provides the physical structure and is essential for both safety and energy efficiency.

It contains a thick insulation layer, typically made of high-temperature ceramic fiber, which minimizes heat loss to the surroundings. This is all enclosed in a durable outer casing, usually made of steel, to protect the internal components.

The Atmosphere Control System: Defining the Environment

This system is what makes a tube furnace so versatile for research. It allows the user to control the gaseous environment inside the tube.

It can be used to create a vacuum with a pump, introduce an inert gas like argon or nitrogen to prevent oxidation, or flow a specific reactive gas for processes like combustion or gasification.

Understanding Key Design Trade-offs

The selection of each component involves trade-offs between performance, cost, and operational flexibility. Understanding these is crucial for choosing the right furnace.

Tube Material: Temperature vs. Versatility

A quartz tube is transparent, which can be useful for visual observation, but it is typically limited to temperatures below 1200°C.

An alumina tube is opaque but can withstand much higher temperatures (often up to 1800°C). It offers greater thermal and mechanical stability for demanding applications.

Heating Element: Cost vs. Maximum Temperature

The maximum operating temperature of a furnace is dictated by its heating elements, which come with different costs. Furnaces with simple resistance wires are the most affordable, while those using MoSi2 elements to reach extreme temperatures are a significant investment.

Furnace Design: Standard vs. Split Tube

A standard tube furnace has a solid, continuous body. A split tube furnace, however, is built in two halves connected by hinges.

This split design allows the furnace to be opened, providing easy access to the tube and sample. This is incredibly useful for experiments with complex setups that are difficult to insert from the end of a long tube.

Making the Right Choice for Your Goal

Your choice of furnace configuration should be driven directly by your primary research objective.

- If your primary focus is high-temperature materials synthesis (>1500°C): You need a furnace with an alumina tube and SiC or MoSi2 heating elements.

- If your primary focus is studying fuel pyrolysis or thermal decomposition: A robust atmosphere control system with precise gas flow and vacuum capability is your most critical feature.

- If your primary focus is observing reactions visually or working below 1200°C: A standard furnace with a quartz tube is the most practical and cost-effective choice.

- If your primary focus is process development with frequent setup changes: A split-tube design will provide invaluable convenience and improve your workflow efficiency.

By understanding how these fundamental components function together, you can confidently select and operate the ideal furnace to achieve your specific scientific goals.

Summary Table:

| Component | Key Function | Common Materials/Examples |

|---|---|---|

| Furnace Tube | Houses the sample and reaction | Quartz, Alumina |

| Heating System | Generates high temperatures | Resistance wires, SiC rods, MoSi2 rods |

| Temperature Control | Maintains precise temperature | Thermocouple, PID controller |

| Furnace Body | Provides insulation and safety | Ceramic fiber, Steel casing |

| Atmosphere Control | Manages internal gas environment | Vacuum pumps, Inert/reactive gases |

Ready to elevate your high-temperature experiments with a custom drop tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental requirements are met precisely. Contact us today to discuss how our expertise can optimize your lab's performance and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability