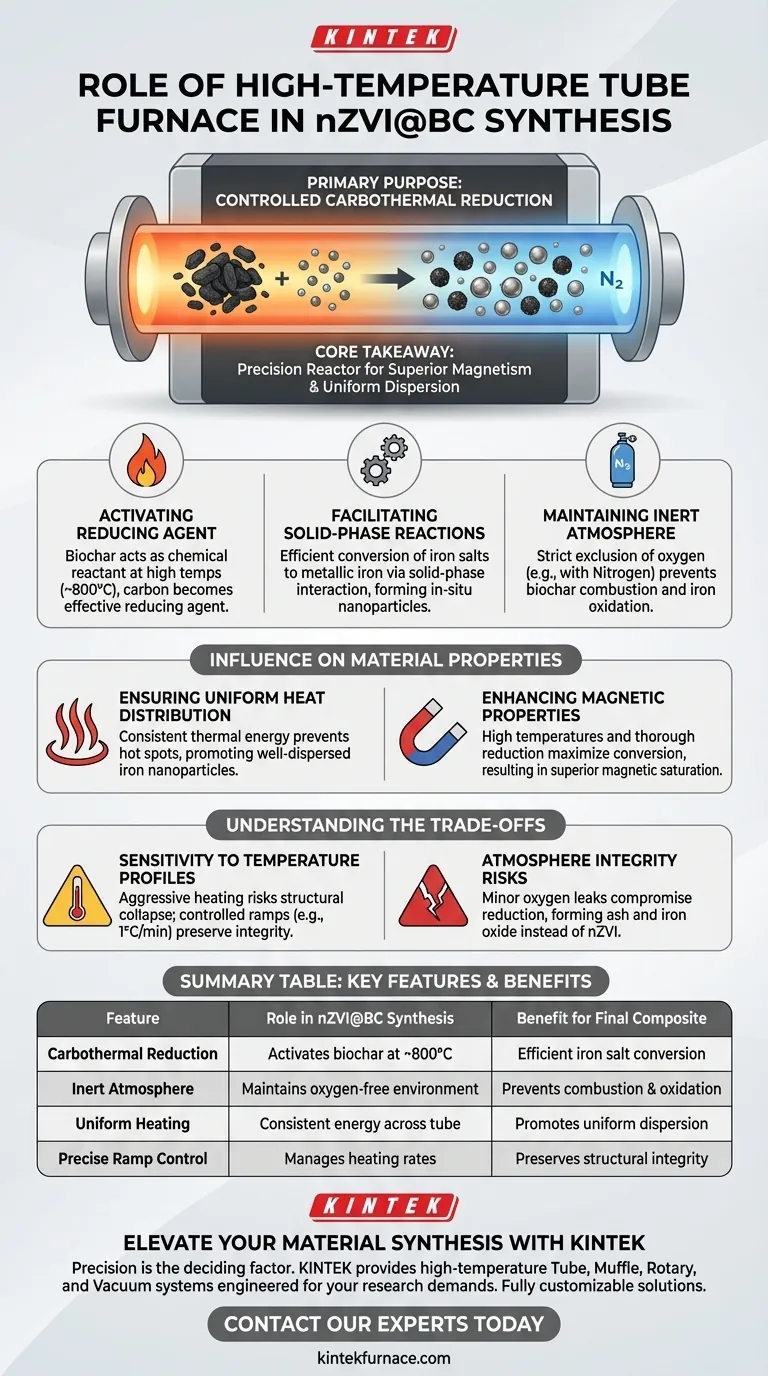

The primary purpose of a high-temperature tube furnace in synthesizing nZVI@BC composites is to create a controlled reaction environment that drives carbothermal reduction. By maintaining a precise, high-temperature setting (often around 800°C) under an inert atmosphere, the furnace enables the carbon within the biochar to act as a reducing agent, converting supported iron salts directly into metallic iron nanoparticles.

Core Takeaway The tube furnace serves as a precision reactor that facilitates a solid-phase chemical reaction between the carbon carrier and iron precursors. Its ability to provide uniform heat and a strictly oxygen-free environment is the deciding factor in producing composites with superior magnetism and uniform nanoparticle dispersion.

The Role of the Furnace in Chemical Synthesis

Activating the Reducing Agent

In this process, the biochar is not just a physical support; it is a chemical reactant.

The tube furnace provides the thermal energy required to activate the carbon lattice within the biochar. At high temperatures, this carbon becomes an effective reducing agent capable of stripping oxygen from iron salts to form zero-valent iron.

Facilitating Solid-Phase Reactions

The conversion of iron salts to metallic iron in this context is a solid-phase reaction.

The furnace ensures this reaction occurs efficiently by maintaining the necessary kinetic energy for the iron source and the carbon carrier to interact. This interaction results in the in-situ formation of nanoparticles directly on the support structure.

Maintaining an Inert Atmosphere

A critical function of the tube furnace is the containment of a specific gas environment, typically nitrogen.

By strictly excluding oxygen during the heating phase, the furnace prevents the biochar from burning away and protects the newly formed nanoscale iron from immediate oxidation. This control is essential for the successful carbonization of the precursor material.

Influence on Material Properties

Ensuring Uniform Heat Distribution

The geometry and heating elements of a tube furnace are designed to wrap the sample in consistent thermal energy.

This uniformity is vital for preventing "hot spots" that could lead to uneven particle growth. Uniform heating ensures the iron nanoparticles are well-dispersed across the biochar matrix, rather than clumped together.

Enhancing Magnetic Properties

The quality of the final composite's magnetism is directly tied to the efficiency of the reduction process.

By sustaining high temperatures (e.g., 800°C) consistently, the furnace maximizes the conversion rate of iron salts to metallic iron. This thorough reduction results in a material with superior magnetic saturation, essential for applications like magnetic separation.

Understanding the Trade-offs

Sensitivity to Temperature Profiles

While the furnace provides high heat, the rate at which this temperature is reached (ramp rate) is critical.

Aggressive heating can cause structural collapse or uneven carbonization, while distinct heating ramps (such as 1 °C per minute) are often necessary to preserve dimensional accuracy. Deviating from the optimal profile can result in poor dispersion or low surface area.

Atmosphere Integrity Risks

The effectiveness of the furnace is entirely dependent on the integrity of the inert atmosphere.

Even minor leaks in the gas lines or tube seals will introduce oxygen at high temperatures. This immediately compromises the carbothermal reduction, turning the biochar into ash and the iron into iron oxide rather than zero-valent iron.

Making the Right Choice for Your Goal

When configuring your tube furnace for nZVI@BC synthesis, consider your specific objectives:

- If your primary focus is maximization of magnetic saturation: Ensure the furnace can maintain a stable hold at the peak temperature (e.g., 800°C) to allow for complete reduction of the iron salts.

- If your primary focus is nanoparticle dispersion: Prioritize a furnace with excellent thermal uniformity and utilize a slower heating ramp to control the nucleation and growth of particles.

Success in this synthesis relies not just on reaching a high temperature, but on the precise control of the thermal and atmospheric environment during the reduction phase.

Summary Table:

| Feature | Role in nZVI@BC Synthesis | Benefit for Final Composite |

|---|---|---|

| Carbothermal Reduction | Activates biochar as a reducing agent at ~800°C | Efficient conversion of iron salts to metallic iron |

| Inert Atmosphere | Maintains strictly oxygen-free environment | Prevents biochar combustion and iron oxidation |

| Uniform Heating | Ensures consistent energy across the tube | Promotes uniform nanoparticle dispersion and prevents clumping |

| Precise Ramp Control | Manages heating rates (e.g., 1°C/min) | Preserves structural integrity and surface area |

Elevate Your Material Synthesis with KINTEK

Precision is the deciding factor in producing high-performance nZVI@BC composites. Backed by expert R&D and world-class manufacturing, KINTEK provides high-temperature Tube, Muffle, Rotary, and Vacuum systems engineered to deliver the uniform heat and atmosphere integrity your research demands.

Whether you need custom CVD systems or lab-scale furnaces for carbothermal reduction, our solutions are fully customizable to meet your unique project specifications.

Ready to achieve superior magnetism and nanoparticle dispersion? Contact our experts today to find the perfect thermal processing solution for your laboratory.

Visual Guide

References

- Chathuri Peiris, Todd Mlsna. Comparative Study of Biocarbon-Supported Iron Nanoparticle Composites (nZVI@BC) Synthesized by Carbothermal Versus Borohydride Reductions for Heavy Metal Removal. DOI: 10.1021/acssusresmgt.5c00250

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the primary functions of a precision gas filtration device? Maximize Data Integrity in Drop Tube Furnaces

- How does the use of a tube furnace enhance cellulose-amine materials? Unlock Superior Porosity & Surface Area

- How was the uneven heating problem in tubular furnaces solved? Achieve Perfect Heat Uniformity with Advanced Designs

- What are the applications of a tube furnace? Master Precise Thermal Processing for Advanced Materials

- How do three-zone tube furnaces contribute to energy and resource efficiency? Boost Lab Performance with Precision Heating

- Why is a tube furnace with precise temperature control required for CuSbSe2 thin films? Achieve High Phase Purity

- What features enable precise temperature control in a vertical tube furnace? Unlock Superior Thermal Accuracy for Your Lab

- Why is high-purity quartz tube vacuum sealing required for Ag2S1-xTex? Protect Your Semiconductor Synthesis