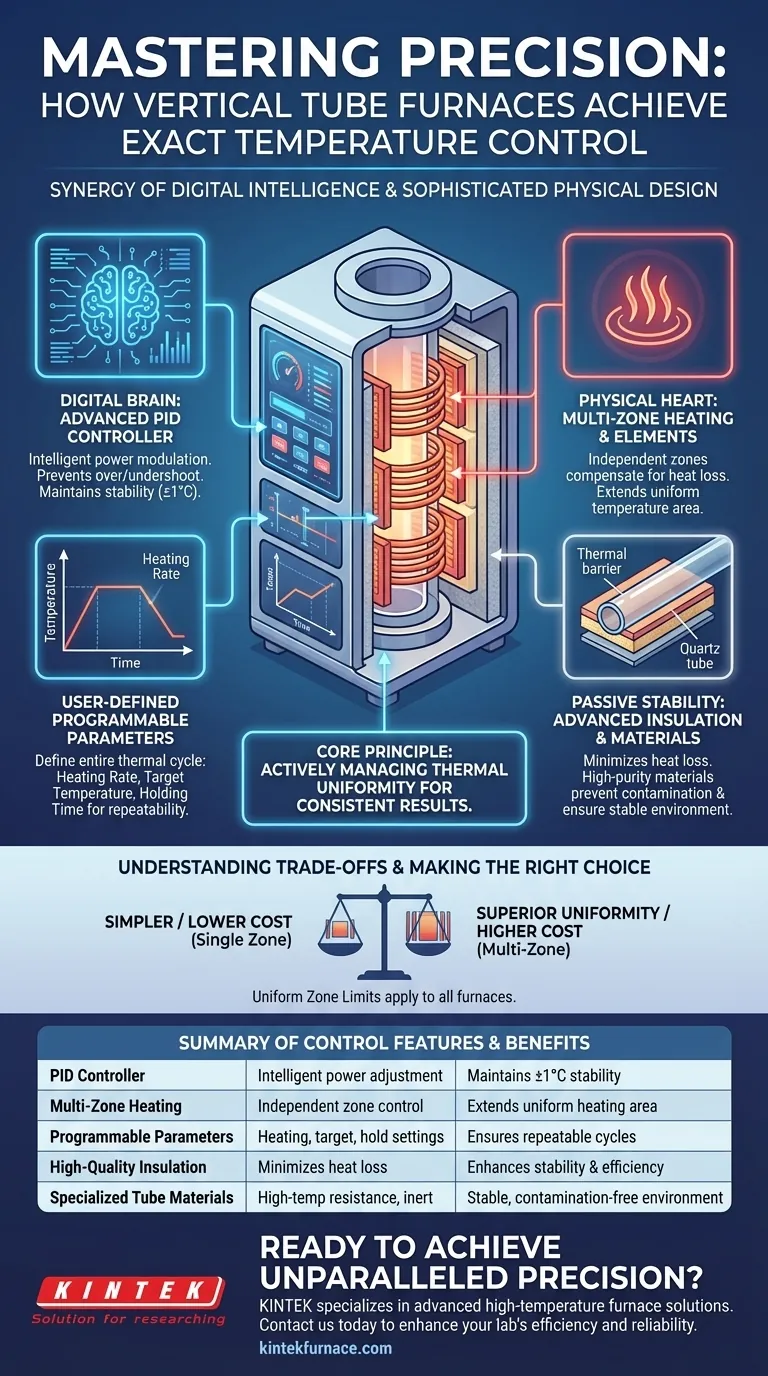

Precise temperature control in a vertical tube furnace is achieved through a synergy of an advanced digital control system and a sophisticated physical furnace design. This system relies on a PID (Proportional-Integral-Derivative) controller to intelligently manage power, while the furnace's construction, including its heating zones and insulation, creates a stable thermal environment. This combination allows for not just reaching a target temperature, but also controlling the heating rate and holding it with exceptional stability.

The core principle of precise temperature control is not just setting a temperature, but actively managing thermal uniformity. True precision comes from a system that can create a consistent temperature profile across the entire sample area, which is essential for repeatable, high-quality results in material science and production.

The Core Components of Temperature Control

Achieving precision requires several components working in concert. It is a system-level feature, not the result of a single part.

The Digital Brain: The PID Controller

A PID controller is the heart of the modern furnace's control system. Unlike a simple thermostat that just turns heating on or off, a PID controller is constantly making adjustments.

It automatically modulates heating power to prevent overshooting or undershooting the target temperature. By learning the furnace's thermal characteristics, it can maintain a stable temperature with minimal fluctuation, often within ±1°C.

The User-Defined Profile: Programmable Parameters

An advanced control system allows you to define the entire thermal process from start to finish. This goes beyond a single temperature setpoint.

Key programmable parameters include:

- Heating Rate: The speed (e.g., degrees per minute) at which the furnace temperature rises.

- Target Temperature: The desired final temperature for processing.

- Holding Time: The duration the furnace will maintain the target temperature.

This programmability ensures the entire heat treatment cycle is controlled and repeatable.

The Physical Heart: Heating Elements and Zones

The physical design of the heating chamber is critical. High-performance furnaces often use multiple heating zones along the length of the tube.

Each zone can be controlled independently, allowing the system to compensate for natural heat loss and create a highly uniform temperature profile across a longer area. The heating elements themselves—often made of graphite, molybdenum, or tungsten—are chosen for their ability to perform consistently at very high temperatures.

Passive Stability: Insulation and Tube Materials

Excellent control is only possible within a stable environment. High-quality insulation minimizes heat loss to the surroundings, making the temperature easier for the PID controller to manage.

Furthermore, the furnace tube, which contains the sample, must be made of a material like high-purity quartz or ceramic. These materials ensure high-temperature resistance and chemical inertness, preventing contamination and maintaining a stable operational environment.

Understanding the Trade-offs

While maximum precision is often desired, it involves trade-offs in complexity and cost.

Control Complexity vs. Simplicity

A single-zone furnace is simpler to operate but will have a shorter uniform temperature zone. A multi-zone furnace provides far superior uniformity over a larger area but requires more sophisticated setup and programming to balance the zones correctly.

Cost of Precision

Features that enhance precision—such as multi-zone controls, advanced PID algorithms, and higher-grade heating elements—directly increase the furnace's cost. The level of uniformity required by your application is the primary driver of the final price.

Physical and Operational Limits

Even the most advanced furnace has a specified "uniform zone." This is the section of the tube where the temperature matches the setpoint within the stated tolerance (e.g., ±1°C). It is critical to know this length and ensure your sample is placed entirely within it for consistent results.

Making the Right Choice for Your Process

Selecting a furnace requires matching its control capabilities to your specific goals.

- If your primary focus is high-value materials or process repeatability (e.g., aerospace components, medical implants): Prioritize a furnace with multiple, independently controlled heating zones and an advanced PID controller.

- If your primary focus is general heat treatment or educational use: A single-zone furnace with a reliable PID controller often provides sufficient precision at a more accessible cost.

- If you are working with sensitive atmospheres or vacuums: Ensure the furnace tube material and system seals are rated for your specific process to maintain both thermal and atmospheric integrity.

Understanding these features empowers you to look beyond the maximum temperature and select a furnace based on the control and uniformity your work truly demands.

Summary Table:

| Feature | Role in Temperature Control | Key Benefit |

|---|---|---|

| PID Controller | Intelligently adjusts power to prevent overshoot/undershoot | Maintains stability within ±1°C |

| Multi-Zone Heating | Independently controls zones for uniform temperature profile | Extends uniform heating area |

| Programmable Parameters | Allows setting of heating rate, target temp, and hold time | Ensures repeatable thermal cycles |

| High-Quality Insulation | Minimizes heat loss to surroundings | Enhances stability and efficiency |

| Specialized Tube Materials | Resists high temps and prevents contamination | Maintains a stable, inert environment |

Ready to achieve unparalleled precision in your thermal processes? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Vertical Tube Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're in aerospace, medical implants, or general research. Don't settle for less—contact us today to discuss how our furnaces can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability