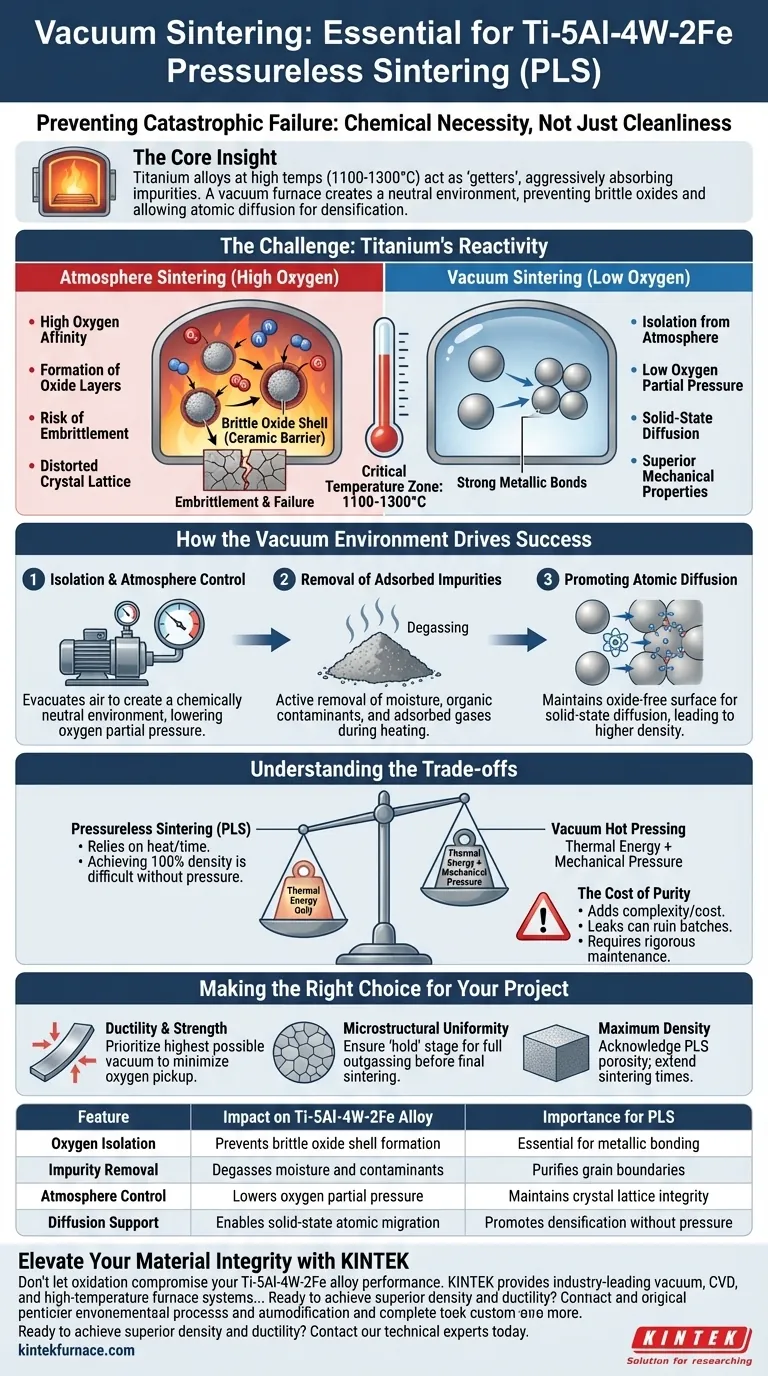

Preventing catastrophic material failure is the primary reason for using a vacuum sintering furnace. For Ti-5Al-4W-2Fe alloys, the vacuum environment is not merely a method of keeping the chamber clean; it is a chemical necessity. At sintering temperatures (1100-1300°C), titanium becomes highly reactive, and without a vacuum to isolate the alloy from oxygen and nitrogen, the material will suffer from severe embrittlement and fail to form strong metallic bonds.

The Core Insight Titanium alloys act as "getters" at high temperatures, aggressively absorbing impurities from the air. A vacuum furnace creates a neutral environment that lowers oxygen partial pressure, preventing the formation of brittle oxides and allowing the atomic diffusion necessary for the alloy to densify and strengthen.

The Challenge: Titanium's Reactivity

The Oxygen Affinity

Titanium and aluminum (a key component of your Ti-5Al-4W-2Fe alloy) possess an extremely high affinity for oxygen.

If you attempt to sinter these materials in air or a standard atmosphere, they will react immediately. Instead of fusing into a solid metal, the powder particles will form oxide layers (like a ceramic shell) that act as barriers to bonding.

The Risk of Embrittlement

When titanium absorbs oxygen or nitrogen, the interstitial elements distort the crystal lattice.

This causes embrittlement, drastically reducing the ductility of the final part. Instead of a tough, high-strength alloy, you produce a material that is prone to cracking and shattering under stress.

The Critical Temperature Zone

The pressureless sintering (PLS) process for this specific alloy requires temperatures between 1100°C and 1300°C.

While this heat is necessary to activate atomic diffusion, it is also the range where chemical reactivity with the atmosphere is most aggressive. The vacuum furnace effectively pauses this chemical attack, allowing the heat to do its work without side effects.

How the Vacuum Environment Drives Success

Isolation and Atmosphere Control

The vacuum furnace operates on the principle of low-pressure sintering. By evacuating air, it creates an environment that is chemically neutral relative to the alloy.

This effectively isolates the Ti-5Al-4W-2Fe from the atmosphere. By significantly lowering the oxygen partial pressure, the furnace ensures that the surface of the metal powder remains metallic rather than oxidized.

Removal of Adsorbed Impurities

Metal powders often contain moisture, organic contaminants, or adsorbed gases on their surface before they even enter the furnace.

A high-vacuum environment (e.g., 10^-3 Pa) actively pulls these volatile impurities off the powder surfaces during the heating phase. This "degassing" purifies the grain boundaries, which is essential for structural integrity.

Promoting Atomic Diffusion

For pressureless sintering to work, atoms must migrate across particle boundaries to close pores and create a solid body.

Oxides act as a roadblock to this movement. By maintaining a pure, oxide-free surface, the vacuum facilitates solid-state diffusion. This allows the particles to bond effectively, leading to higher density and superior mechanical properties.

Understanding the Trade-offs

Density Challenges in Pressureless Sintering

While the vacuum is essential for chemistry, relying solely on PLS (Pressureless Sintering) has physical limitations compared to Vacuum Hot Pressing.

In PLS, you rely entirely on thermal energy and time to remove pores. Without mechanical pressure to force particles together, achieving 100% theoretical density is more difficult, even with a perfect vacuum.

The Cost of Purity

Maintaining a high-quality vacuum adds complexity and cost to the process.

Leaks or insufficient vacuum levels (e.g., failing to reach the required Pascal range) can ruin an entire batch. The process requires rigorous equipment maintenance to ensure the "neutral" atmosphere is truly neutral.

Making the Right Choice for Your Project

To maximize the quality of your Ti-5Al-4W-2Fe alloy, consider these strategic priorities:

- If your primary focus is Ductility and Strength: Prioritize the highest possible vacuum level (lowest pressure) to minimize oxygen pickup, as even trace amounts can cause brittleness.

- If your primary focus is Microstructural Uniformity: Ensure your heating profile includes a "hold" stage under vacuum to allow full outgassing of volatiles before the final sintering temperature is reached.

- If your primary focus is Maximum Density: Acknowledge that while a vacuum furnace is essential for chemistry, pressureless sintering may leave residual porosity; extend sintering times to compensate.

In summary, the vacuum furnace provides the only environment in which Ti-5Al-4W-2Fe can sinter without destroying its own mechanical properties through oxidation.

Summary Table:

| Feature | Impact on Ti-5Al-4W-2Fe Alloy | Importance for PLS |

|---|---|---|

| Oxygen Isolation | Prevents brittle oxide shell formation | Essential for metallic bonding |

| Impurity Removal | Degasses moisture and organic contaminants | Purifies grain boundaries |

| Atmosphere Control | Lowers oxygen partial pressure | Maintains crystal lattice integrity |

| Diffusion Support | Enables solid-state atomic migration | Promotes densification without pressure |

Elevate Your Material Integrity with KINTEK

Don't let oxidation compromise your Ti-5Al-4W-2Fe alloy performance. KINTEK provides industry-leading vacuum, CVD, and high-temperature furnace systems engineered to deliver the precise atmospheric control your sintering process demands. Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique laboratory or production needs.

Ready to achieve superior density and ductility? Contact our technical experts today to find the perfect thermal solution for your advanced materials.

Visual Guide

References

- Mai Essam, Nabil Fatahalla. Processing of Ti–5Al–4W–2Fe Alloy Using Different Powder Metallurgy Routes to Improve Its Implementation in Structural Applications. DOI: 10.1007/s13369-024-09834-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key components of a vacuum furnace? Essential Systems for Precision Heat Treatment

- What are the technical advantages of using high-pressure nitrogen quenching? Achieve Precision Heat Treatment

- What types of quenching can be performed in a vacuum furnace? Explore High-Pressure Gas and Oil Quenching

- What makes vacuum furnaces more efficient compared to conventional furnaces? Unlock Superior Heat Treatment and Energy Savings

- Why is a vacuum furnace used for long-term heat exposure experiments on Nb-22.5Cr-5Si alloys? Ensure Data Integrity

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does a constant temperature heating device work with a vacuum chamber for graphene? Master Degradation Testing

- What are the size ranges and common applications of crucible furnaces? Find Your Perfect Fit for Small-Batch Melting