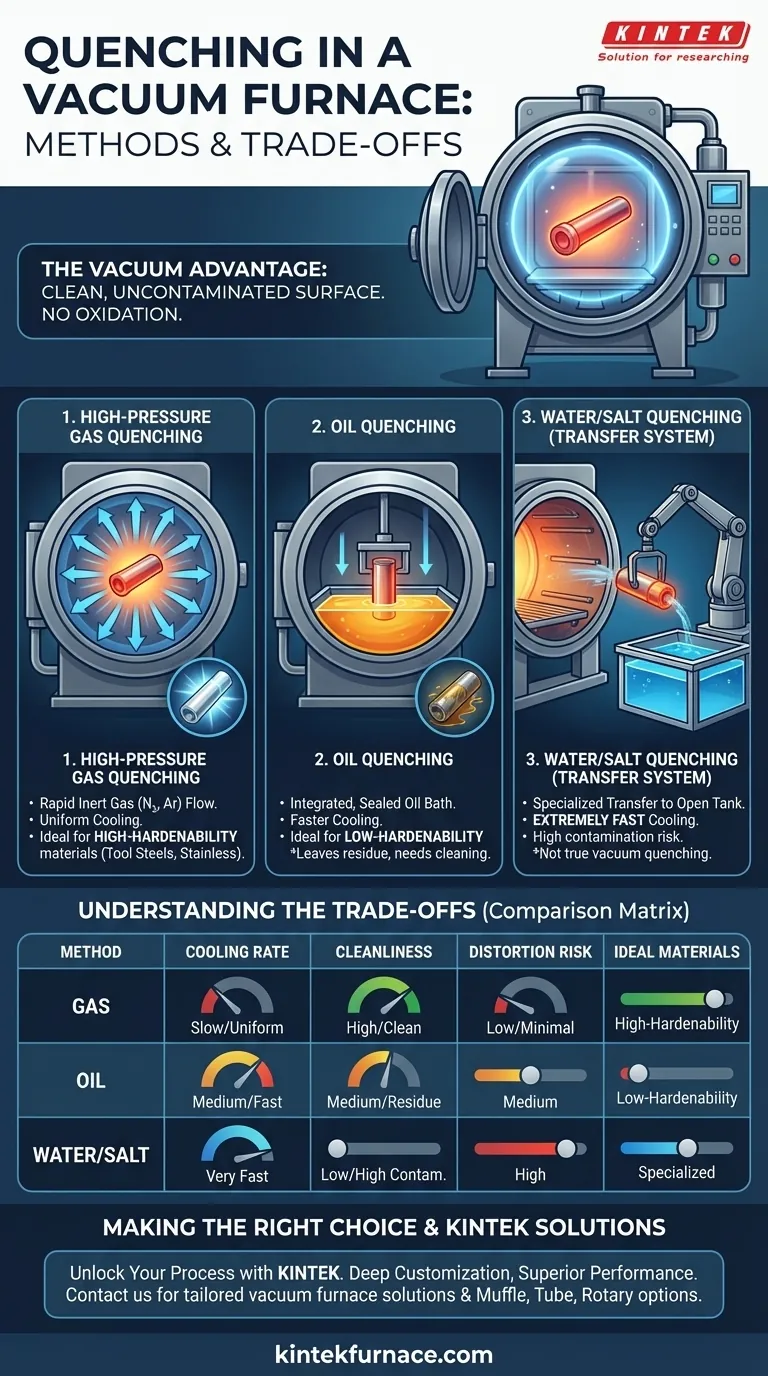

At its core, a vacuum furnace can perform several types of quenching, primarily high-pressure inert gas quenching and oil quenching. While less common, some specialized systems also integrate water or salt quenching capabilities by moving the workload from the vacuum heating chamber to an adjacent liquid quench tank.

The choice of a quenching method in a vacuum furnace is a critical decision that balances the need for a specific cooling rate against the primary benefit of vacuum processing: achieving a pristine, uncontaminated surface finish. The correct method depends entirely on the material's properties and the desired final characteristics.

The Purpose of the Vacuum Environment

Before examining quenching, it's crucial to understand why parts are heated in a vacuum in the first place. The goal is to create an exceptionally clean and controlled atmosphere.

Why Heat in a Vacuum?

Heating metal to high temperatures in the presence of oxygen causes oxidation and scaling. A vacuum removes reactive gases, preventing these surface reactions.

This results in bright, clean parts that often require no subsequent cleaning. It also prevents decarburization, which is the loss of carbon from a steel's surface that can reduce hardness and wear resistance.

The Quenching Challenge

The challenge is to cool the part rapidly enough to achieve the desired hardness (the "quench") without reintroducing contaminants or compromising the clean surface created in the vacuum.

A Breakdown of Vacuum Quenching Methods

The quenching method must be fast enough to lock in the desired metallurgical structure but controlled enough to maintain the benefits of the vacuum process.

High-Pressure Gas Quenching

This is the most common and "native" quenching method for a modern vacuum furnace. After heating, the chamber is rapidly backfilled with a high-pressure, high-flow-rate inert gas, typically nitrogen or argon.

Fans circulate this gas at high velocity to cool the part uniformly. This method is ideal for materials with high hardenability, such as tool steels, high-speed steels, and many stainless and titanium alloys.

Oil Quenching

For steels with lower hardenability, gas quenching may not be fast enough to achieve full hardness. These applications require a vacuum oil quench furnace.

These furnaces have an integrated, sealed oil bath located in a chamber below or adjacent to the heating zone. After heating, the workload is mechanically lowered into the oil to cool rapidly. This is a sealed process, ensuring the vacuum integrity of the heating chamber is not compromised.

Water and Nitrate (Salt) Quenching

Water and molten salt provide even faster cooling rates than oil, but they are highly reactive and volatile. Introducing them directly into a hot vacuum chamber would instantly ruin the vacuum and contaminate the equipment.

Therefore, true "vacuum water quenching" does not exist. Instead, a system would heat the part in vacuum, transfer it under a protective atmosphere to a separate, open quench tank, and then immerse it. This is a multi-step process used only for specialized applications where extremely high cooling rates are non-negotiable.

Understanding the Trade-offs: Gas vs. Liquid

Choosing between gas and liquid quenching involves a series of critical engineering trade-offs.

Cooling Rate vs. Hardenability

A material's hardenability dictates how slowly it can be cooled while still achieving full hardness.

High-hardenability alloys (like A2 tool steel) can be quenched effectively with gas. Lower-hardenability alloys (like 1045 steel) require the faster cooling of a liquid like oil or water.

Part Cleanliness

Gas quenching is the cleanest method. It leaves no residue, and parts emerge from the furnace bright and ready for use.

Oil quenching, while performed in a sealed system, will leave an oil residue on the part that requires a subsequent washing or tempering process to remove.

Distortion and Cracking Risk

High-pressure gas provides the most uniform cooling, which significantly reduces thermal stress and the risk of part distortion or cracking.

Liquid quenches are more aggressive and can create larger temperature gradients across the part, increasing internal stresses and the potential for distortion.

Making the Right Choice for Your Application

Selecting the correct quench method is essential for meeting your component's design specifications.

- If your primary focus is maximum cleanliness and minimal distortion: High-pressure gas quenching is the superior choice, especially for air-hardening tool steels and complex geometries.

- If your primary focus is achieving specified hardness in low-to-medium alloy steels: Oil quenching is often necessary to provide the faster cooling rate that these materials require to transform correctly.

- If your primary focus is cost-effective hardening of simple carbon steels: Vacuum processing may be overkill, and a traditional atmosphere furnace with an open water or brine quench tank is likely more suitable.

Ultimately, matching the quenching method to the material's specific transformation needs is the key to successful heat treatment.

Summary Table:

| Quenching Method | Key Features | Ideal Materials |

|---|---|---|

| High-Pressure Gas Quenching | Clean, uniform cooling, minimal distortion | Tool steels, high-speed steels, stainless and titanium alloys |

| Oil Quenching | Faster cooling, requires residue removal | Low-hardenability steels |

| Water/Salt Quenching | Very fast cooling, specialized transfer systems | Materials needing extreme cooling rates |

Unlock the full potential of your heat treatment processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering superior performance, cleanliness, and efficiency. Contact us today to discuss how our tailored solutions can optimize your quenching applications and achieve your material goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today