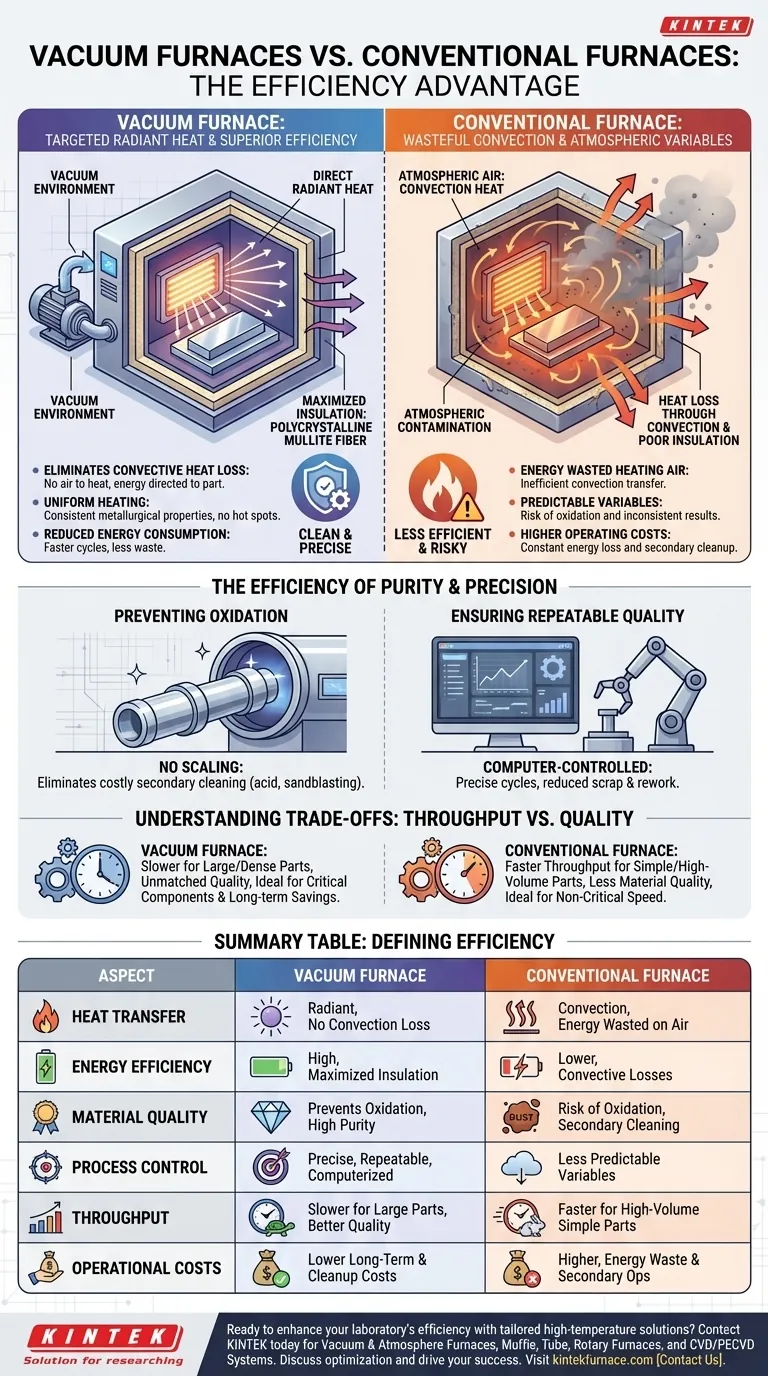

At its core, a vacuum furnace achieves superior efficiency by fundamentally changing how heat is transferred and by creating an ultra-pure environment. Unlike conventional furnaces that waste energy heating air and fighting atmospheric contamination, a vacuum furnace eliminates the air, allowing for highly targeted radiant heating, superior insulation, and processes that produce cleaner, higher-quality parts without secondary cleanup operations.

The true efficiency of a vacuum furnace is not merely about energy savings; it is about process control. By removing the atmosphere, you eliminate uncontrolled variables like convection and oxidation, leading to more precise, repeatable, and materially superior results with less waste.

How a Vacuum Changes the Rules of Heat Transfer

Conventional furnaces operate in air, a medium that transfers heat unpredictably through convection. A vacuum furnace removes this medium, creating an environment where efficiency is designed, not incidental.

Eliminating Convective Heat Loss

In a traditional furnace, a significant amount of energy is wasted heating the air inside the chamber. This heated air then transfers energy to the workpiece via convection, but it also transfers that heat to the furnace walls, leading to constant energy loss.

By evacuating the chamber, a vacuum furnace almost completely eliminates convective heat transfer. There are virtually no air molecules to heat, meaning nearly all the energy is directed where it matters: the part itself.

Focusing on Direct Radiant Heat

With convection removed, heat transfer occurs primarily through thermal radiation. This is a direct, line-of-sight energy transfer from the heating elements to the workpiece.

This allows for exceptionally uniform heating, as the part is evenly bathed in radiant energy. This precision prevents hot spots and ensures consistent metallurgical properties throughout the material, which is a key measure of process efficiency.

Maximizing Insulation Performance

The effectiveness of insulation is dramatically increased in a vacuum. Materials like high-quality polycrystalline mullite fiber are used because they are poor conductors of heat.

In a vacuum, where there is no air to move heat through the insulation, their performance is maximized. Combined with features like double-layer furnace shells, this ensures that the generated heat stays inside the chamber, enabling faster heating cycles while consuming less overall energy.

The Efficiency of Purity and Precision

Beyond thermal dynamics, a vacuum furnace’s efficiency comes from the quality of its output. The controlled environment prevents problems that cost time and money in conventional processes.

Preventing Oxidation and Contamination

The most obvious benefit of a vacuum is the absence of oxygen and other atmospheric contaminants. This prevents surface oxidation (scaling) on metal parts during heat treatment.

This is a massive efficiency gain. It eliminates the need for costly and time-consuming secondary operations like acid cleaning, sandblasting, or machining to remove the scaled layer, saving labor, time, and raw material.

Ensuring Repeatable, High-Quality Results

Modern vacuum furnaces use advanced computer-controlled processes. The absence of atmospheric variables allows for extremely precise and repeatable control over every stage of the cycle, from heating ramps to temperature soaks and cooling.

This level of control ensures that every part achieves the desired metallurgical properties, drastically reducing scrap rates and the need for rework. This repeatability is a critical form of production efficiency for high-value components.

Understanding the Trade-offs: Throughput vs. Quality

While highly efficient in energy use and final quality, a vacuum furnace is not always the fastest option for every application.

The Nuance of Heating Speed

A vacuum furnace's chamber can heat up rapidly due to its excellent insulation. However, heating a large or dense workpiece can sometimes be slower than in a conventional furnace.

This is because it relies solely on radiation. A conventional (or atmosphere) furnace uses convection, where moving hot air can help transfer heat into complex geometries or large parts more quickly, even if it is less energy-efficient overall.

Overall Cycle Time

The vacuum process itself adds time. Pulling a deep vacuum before the heating cycle begins and then often backfilling the chamber with an inert gas for controlled cooling adds minutes to the total production cycle.

Because of this, for high-volume production of simple, low-cost parts, a continuous conveyor belt atmosphere furnace may offer higher throughput (parts per hour), even if it is less efficient per part.

Making the Right Choice for Your Goal

The term "efficiency" must be defined by your primary objective. A vacuum furnace's advantages are clear, but they are most impactful when aligned with specific production goals.

- If your primary focus is material purity and quality: A vacuum furnace is unmatched, as it eliminates oxidation and ensures precise, repeatable metallurgical results for critical components.

- If your primary focus is long-term energy efficiency: A vacuum furnace's superior insulation and elimination of convective heat loss will lead to significantly lower operational costs per cycle.

- If your primary focus is high-volume throughput of simple parts: A conventional or atmosphere furnace may be more "efficient" in terms of pure speed and the number of units processed per hour.

Ultimately, choosing the right furnace requires defining efficiency not just as speed, but as the most effective path to achieving your desired material quality and final cost.

Summary Table:

| Aspect | Vacuum Furnace | Conventional Furnace |

|---|---|---|

| Heat Transfer | Radiant heating, no convection loss | Convection heating, energy wasted on air |

| Energy Efficiency | High due to insulation and no air heating | Lower due to convective losses |

| Material Quality | Prevents oxidation, no scaling, high purity | Risk of oxidation, requires secondary cleaning |

| Process Control | Precise, repeatable with computer control | Less predictable due to atmospheric variables |

| Throughput | Slower for large parts, better for quality | Faster for high-volume, simple parts |

| Operational Costs | Lower long-term energy and cleanup costs | Higher due to energy waste and secondary ops |

Ready to enhance your laboratory's efficiency with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs, delivering superior heat treatment, energy savings, and contaminant-free results. Don't settle for less—contact us today to discuss how we can optimize your processes and drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing