The primary technical advantage of high-pressure nitrogen quenching is the elimination of the vapor film effect, resulting in a highly uniform and predictable cooling process. Unlike liquid media, which can cause irregular cooling due to boiling, high-pressure gas allows for precise control over cooling rates, significantly reducing material distortion while maintaining hardness.

By replacing liquid media with high-pressure nitrogen, you eliminate the Leidenfrost phenomenon—an unpredictable vapor barrier that insulates the metal. This ensures consistent thermal transfer, allowing for precise metallurgical results and minimized dimensional inaccuracies.

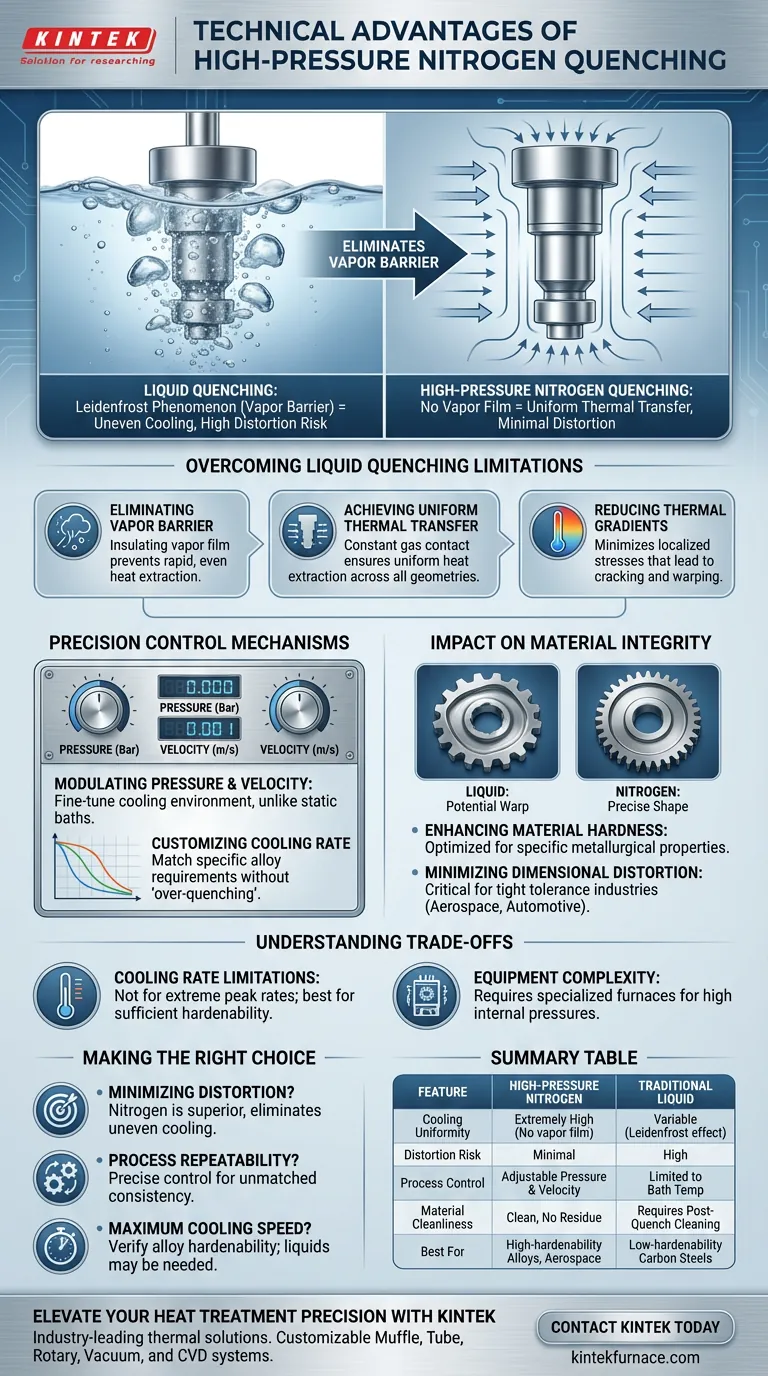

Overcoming Liquid Quenching Limitations

Eliminating the Vapor Barrier

Traditional liquid quenching often suffers from the Leidenfrost phenomenon. This occurs when a vapor film forms around the hot specimen, insulating it and preventing rapid, even heat extraction.

Achieving Uniform Thermal Transfer

High-pressure nitrogen bypasses this "vapor phase" entirely. Because the gas maintains constant contact with the surface, the heat extraction is uniform across the entire geometry of the component.

Reducing Thermal Gradients

The uniformity of gas quenching minimizes localized thermal gradients. This prevents the internal stresses that typically lead to cracking or warping during the cooling cycle.

Precision Control Mechanisms

Modulating Pressure and Velocity

Operators can fine-tune the cooling environment by adjusting two key variables: gas pressure and flow velocity. This level of control is rarely achievable with static liquid baths.

Customizing the Cooling Rate

By manipulating these variables, you can program the cooling rate to match the specific requirements of the alloy. This ensures the material reaches the desired phase transformation without "over-quenching."

Impact on Material Integrity

Enhancing Material Hardness

The ability to manage the cooling curve precisely allows for optimized hardness. The process can be tuned to achieve specific metallurgical properties required for high-performance applications.

Minimizing Dimensional Distortion

Because the cooling is uniform and controlled, the final component retains its shape more accurately. This reduction in distortion is critical for industries like aerospace and automotive, where dimensional tolerances are tight.

Understanding the Trade-offs

Cooling Rate Limitations

While high-pressure nitrogen is versatile, it may not achieve the extreme peak cooling rates of water or low-viscosity oils. It is most effective for materials with sufficient hardenability.

Equipment Complexity

Implementing high-pressure gas quenching requires specialized furnaces capable of sustaining high internal pressures. This contrasts with simpler containment systems used for oil or water quenching.

Making the Right Choice for Your Goal

To determine if high-pressure nitrogen is the correct medium for your heat treatment process, consider your specific metallurgical targets:

- If your primary focus is minimizing distortion: High-pressure nitrogen is the superior choice, as it eliminates the uneven cooling caused by vapor films.

- If your primary focus is process repeatability: The ability to precisely control pressure and flow velocity offers a level of consistency that liquid baths cannot match.

- If your primary focus is maximum cooling speed: Verify that your specific alloy has enough hardenability to be fully transformed by gas cooling, as liquids may still be required for lower-hardenability metals.

Precise control over the cooling medium is the single most effective way to ensure predictable, high-quality heat treatment results.

Summary Table:

| Feature | High-Pressure Nitrogen Quenching | Traditional Liquid Quenching |

|---|---|---|

| Cooling Uniformity | Extremely High (No vapor film) | Variable (Leidenfrost effect) |

| Distortion Risk | Minimal due to uniform gradients | High due to irregular cooling |

| Process Control | Adjustable gas pressure & velocity | Limited to bath temperature |

| Material Cleanliness | Clean, no residue left on parts | Requires post-quench cleaning |

| Best For | High-hardenability alloys & aerospace | Low-hardenability carbon steels |

Elevate Your Heat Treatment Precision with KINTEK

Don't let unpredictable vapor barriers compromise your material integrity. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our diverse range of Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet your specific cooling and pressure requirements.

Whether you are minimizing dimensional distortion for aerospace components or seeking superior process repeatability, our high-temp furnaces deliver the control you need. Contact KINTEK today to discuss your unique project needs and discover how our advanced furnace technology can optimize your metallurgical results.

Visual Guide

References

- Artificial Intelligence Modeling of the Heterogeneous Gas Quenching Process for Steel Batches Based on Numerical Simulations and Experiments. DOI: 10.3390/dynamics4020023

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum impregnation device facilitate PCMs into biomimetic composites? Boost Filling Rates to 96%

- How does a vacuum furnace prevent oxidation and decarburization? Achieve Flawless Metal Processing with Precision Control

- What is the temperature of a vacuum furnace brazing? Optimize Your Joint Strength and Cleanliness

- What role do vacuum furnaces play in the automotive industry? Enhance Durability and Performance in Vehicle Parts

- How does vacuum heat treating work in terms of temperature and time control? Master Precise Material Transformations

- What is the function of a high-vacuum furnace in tantalum carburization? Purity & Reaction Precision

- Why does the simulation of magnesium alloy distillation require high precision? Master Vacuum for Purity