At its core, a vacuum furnace prevents oxidation and decarburization by physically removing the reactive atmosphere that causes these chemical changes. By using powerful pumps to evacuate the air from a sealed heating chamber, the furnace creates an environment with extremely low levels of oxygen. Without oxygen present, the metal workpiece can be heated to very high temperatures without forming an oxide layer (rust) or losing surface carbon.

The true value of a vacuum furnace is not merely preventing rust; it is about achieving absolute control over the material's surface chemistry and structural integrity. This control enables the production of high-purity, dimensionally stable components that are impossible to create in a standard atmospheric furnace.

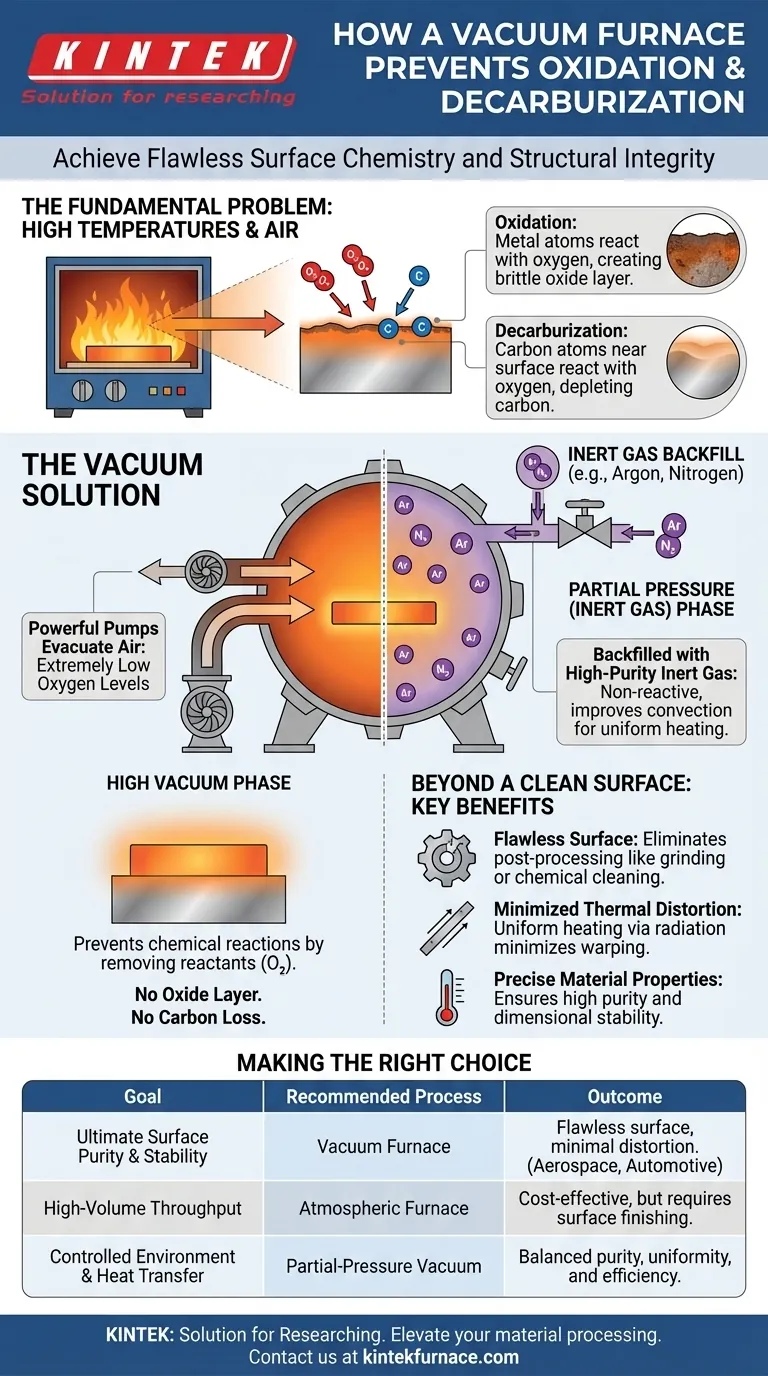

The Fundamental Problem: High Temperatures and Air

Heating metals in the presence of a normal atmosphere creates predictable and often undesirable chemical reactions. Understanding these reactions is key to appreciating why a vacuum is so effective.

How Oxidation Occurs

At elevated temperatures, metal atoms become highly reactive. They readily bond with oxygen molecules in the air, a process known as oxidation. This creates a brittle, often discolored layer of metal oxide on the workpiece's surface.

How Decarburization Occurs

For carbon-based alloys like steel, a similar reaction happens with carbon. At high heat, carbon atoms near the surface can react with oxygen in the atmosphere. This reaction depletes the carbon content of the surface layer, a process called decarburization, which results in a softer, weaker surface.

The Vacuum Solution

A vacuum furnace directly addresses this problem by removing the primary reactant: oxygen. Vacuum pumps evacuate the heating chamber to a specific, low-pressure level. By drastically reducing the number of oxygen and other gas molecules, the furnace effectively starves the chemical reactions of oxidation and decarburization before they can begin.

Beyond a Vacuum: The Role of Partial Pressure

While a high vacuum is effective, the process is often refined by using inert gases to create a precisely controlled, non-reactive atmosphere.

The Process of Backfilling

In many applications, the chamber is first evacuated to remove the air. Then, it is partially or fully "backfilled" with a high-purity, non-reactive (inert) gas, most commonly argon or nitrogen.

Why Use an Inert Gas?

This partial pressure environment serves two purposes. First, it continues to prevent oxidation and decarburization because the inert gas will not react with the hot metal. Second, the gas molecules improve heat transfer through convection, often leading to more uniform heating and faster cycle times compared to heating in a hard vacuum, which relies solely on radiation.

Understanding the Broader Implications

The choice to use a vacuum furnace is driven by benefits that extend beyond a clean surface. It is about the final quality and integrity of the component itself.

The Primary Benefit: A Flawless Surface

The most obvious advantage is a bright, clean, and unaltered workpiece surface straight out of the furnace. This eliminates the need for post-processing steps like grinding, blasting, or chemical cleaning to remove an oxide or decarburized layer, saving time and preserving the part's precise dimensions.

A Key Advantage: Minimized Thermal Distortion

In a vacuum, heat is transferred primarily through radiation, not convection. This method heats the workpiece more slowly and uniformly, resulting in a much smaller temperature difference between the part's surface and its core. This reduction in thermal stress significantly minimizes warping and distortion, which is critical for complex, high-precision components.

The Main Limitation: Cost and Cycle Time

This high level of control comes at a cost. Vacuum furnaces are more complex and expensive to operate than traditional atmospheric furnaces. The process of pumping down the chamber and the slower heating rates also result in longer overall cycle times.

Making the Right Choice for Your Goal

Selecting the correct thermal process requires balancing the desired material properties with production efficiency and cost.

- If your primary focus is ultimate surface purity and dimensional stability: A vacuum furnace is the definitive choice for eliminating oxidation and minimizing distortion on critical components.

- If your primary focus is high-volume throughput where some surface finishing is acceptable: A conventional atmospheric furnace may provide a more cost-effective solution.

- If you need to prevent chemical reactions while optimizing heat transfer: A partial-pressure vacuum process using an inert gas backfill offers a balanced and highly controlled environment.

Ultimately, using a vacuum furnace is a decision to prioritize the metallurgical and dimensional integrity of the final product above all else.

Summary Table:

| Aspect | Key Details |

|---|---|

| Mechanism | Removes oxygen via vacuum pumps and inert gas backfilling to prevent chemical reactions. |

| Benefits | Prevents oxidation and decarburization, minimizes thermal distortion, eliminates post-processing. |

| Applications | Ideal for high-purity, dimensionally stable components in industries like aerospace and automotive. |

| Limitations | Higher cost and longer cycle times compared to atmospheric furnaces. |

Elevate your material processing with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, tailored to your unique needs with deep customization. Achieve flawless oxidation and decarburization prevention for superior component quality—contact us today to discuss how we can optimize your laboratory's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density