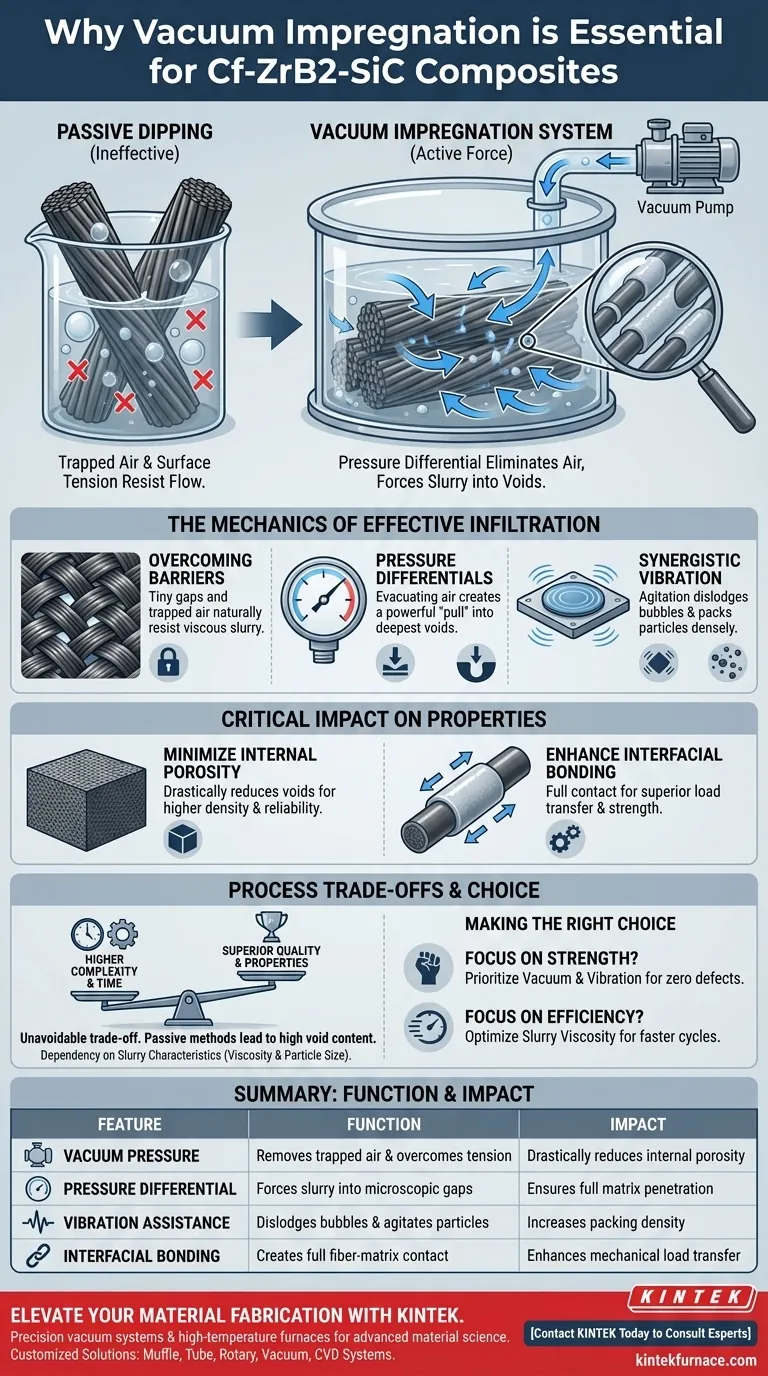

A vacuum impregnation system is strictly necessary for fabricating Cf-ZrB2-SiC composites because it provides the active force required to drive ceramic slurry into the microscopic gaps within carbon fiber bundles. Unlike simple dipping or soaking, this process utilizes pressure differentials to overcome the natural resistance of the fabric, ensuring the matrix material fully penetrates the fiber architecture.

The primary function of this system is to eliminate trapped air and force the ceramic matrix into the fiber bundles, thereby reducing internal porosity and guaranteeing the interfacial bonding strength required for high-performance composites.

The Mechanics of Effective Infiltration

Overcoming Physical Barriers

Carbon fiber fabrics consist of tightly woven bundles containing thousands of individual filaments. These bundles create tiny, intricate gaps that naturally resist the penetration of viscous ceramic slurries due to surface tension and trapped air.

The Role of Pressure Differentials

A vacuum impregnation system solves this by creating a pressure differential. By evacuating the air from the chamber, the system removes the atmospheric resistance inside the fabric, effectively "pulling" the slurry into the deepest voids of the fiber architecture.

Synergistic Vibration

To maximize efficiency, these systems often combine vacuum pressure with vibration-assisted functions. While the vacuum pulls the slurry in, the vibration agitates the mixture, helping to dislodge stubborn air bubbles and allowing ceramic particles to settle more densely into the fiber gaps.

Critical Impact on Material Properties

Minimizing Internal Porosity

The most significant threat to composite integrity is porosity—voids where the matrix failed to penetrate. Vacuum impregnation is the most effective method for drastically reducing internal porosity, which directly correlates to the composite's final density and structural reliability.

Enhancing Interfacial Bonding

For a composite to act as a single unit, the load must transfer effectively between the fibers and the ceramic matrix. By ensuring the slurry fully coats individual fibers rather than just the surface of the bundle, the system creates the necessary contact area for strong interfacial bonding strength.

Understanding the Process Trade-offs

Complexity vs. Quality

Using a vacuum impregnation system adds complexity and time to the fabrication process compared to ambient pressure infiltration. However, this trade-off is unavoidable; relying on passive infiltration methods will almost invariably result in a material with high void content and poor mechanical properties.

Dependency on Slurry Characteristics

While the vacuum system is powerful, it is not a cure-all for poorly prepared materials. The efficacy of the impregnation is still dependent on the viscosity and particle size of the ceramic slurry; if the slurry is too thick, even high vacuum may fail to achieve full penetration.

Making the Right Choice for Your Goal

To ensure you are utilizing this process effectively, consider your specific performance requirements:

- If your primary focus is mechanical strength: Prioritize the combination of vacuum and vibration to minimize every possible micro-void, as these are the initiation points for cracks.

- If your primary focus is process efficiency: Optimize the slurry viscosity to match your vacuum capabilities, ensuring the fluid flows easily into the fiber bundles without requiring excessive cycle times.

Successful fabrication relies on the understanding that vacuum impregnation is not just a dipping step, but a forced integration of two distinct materials.

Summary Table:

| Feature | Function in Cf-ZrB2-SiC Fabrication | Impact on Final Composite |

|---|---|---|

| Vacuum Pressure | Removes trapped air and overcomes surface tension | Drastically reduces internal porosity |

| Pressure Differential | Forces ceramic slurry into microscopic fiber gaps | Ensures full matrix penetration |

| Vibration Assistance | Dislodges air bubbles and agitates particles | Increases packing density of the matrix |

| Interfacial Bonding | Creates full contact between fiber and matrix | Enhances mechanical load transfer |

Elevate Your Material Fabrication with KINTEK

Precision in composite manufacturing starts with superior thermal and pressure control. KINTEK provides high-performance vacuum systems and high-temperature furnaces designed to meet the rigorous demands of advanced material science. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique research or production needs.

Whether you are refining Cf-ZrB2-SiC composites or developing next-generation ceramics, our engineers are ready to help you optimize your process and achieve zero-defect results.

Contact KINTEK Today to Consult with our Experts

Visual Guide

References

- Sirui Gong, Yukui Wang. Methodology for Surface Reconstruction and Prediction Based on the Electrical Discharge Machining Removal Mechanism of Cf-UHTC Materials. DOI: 10.3390/ma18020371

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Vacuum Induction Melting Furnace

People Also Ask

- What are the primary functions of a vacuum furnace? Achieve Superior Material Processing in a Controlled Environment

- What is the basic structure of a vacuum furnace? Discover Its Core Components and Functions

- Why is a vacuum required for sulfur gas-phase diffusion? Boost Se-ZnS/HSC Cathode Sulfur Loading to 68.2 wt.%

- What role does carbonization in a high-temperature furnace play for 2D COF membranes? Enhance Stability & Conductivity

- How does a vacuum furnace prevent oxidation of metals? Unlock Purity and Strength in Heat Treatment

- What role does a floating zone furnace play in high-purity superconducting growth? Achieve Crucible-Free Excellence

- Why is pre-drying Rubidium Chloride raw materials essential? Ensure Safety and Purity in Vacuum Distillation

- How does a vacuum furnace create its working environment? Uncover the Secrets to Purity and Precision