Vacuum drying is the critical process step utilized to ensure the structural integrity and density of Al2O3/PTFE composites. It is specifically employed to thoroughly remove residual moisture and solvents from cleaned alumina particles at controlled, moderate temperatures—typically around 80°C.

By lowering the boiling point of liquids, vacuum drying prevents the "clumping" of particles caused by moisture while eliminating the risk of steam-induced defects during high-temperature sintering.

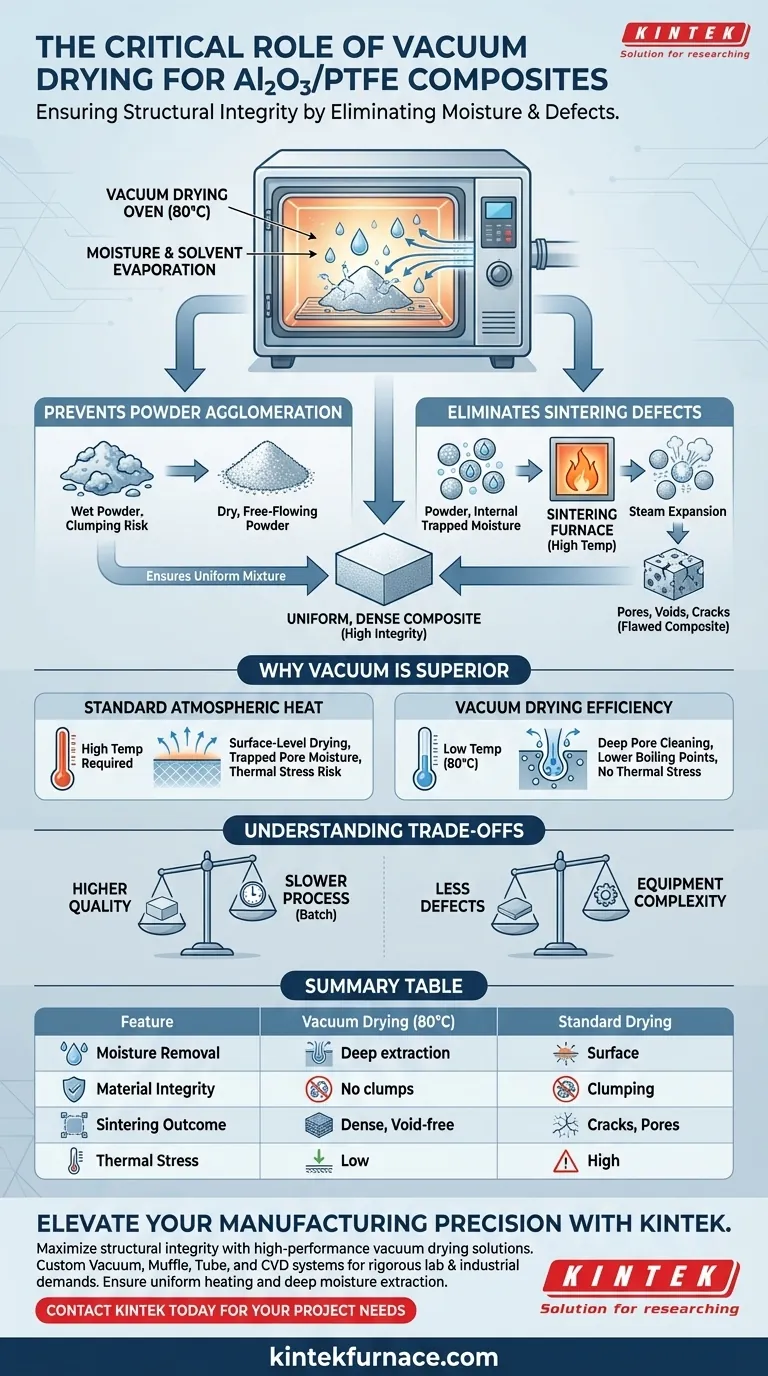

The Mechanics of Defect Prevention

Preventing Powder Agglomeration

Moisture acts as a binding agent between fine powder particles. If alumina (Al2O3) particles are not perfectly dry, they tend to stick together.

Vacuum drying effectively removes this moisture at the microscopic level.

This ensures the powder remains free-flowing and does not form hard agglomerates. Preventing these clumps is vital for achieving a uniform mixture with the PTFE matrix later in the process.

Eliminating Sintering Defects

The most dangerous threat to a composite material is trapped moisture during the high-temperature sintering phase.

If water remains within the powder, it will rapidly vaporize and expand when heated during sintering.

This expansion creates pores, voids, or cracks inside the material. By using a vacuum oven beforehand, you guarantee the removal of volatiles, ensuring the final composite is dense and free of structural voids.

Why Vacuum is Superior to Standard Heat

Low-Temperature Efficiency

The primary reference notes that this process occurs at 80°C.

Under standard atmospheric pressure, effectively removing all solvents might require higher temperatures that could alter surface chemistry.

The vacuum environment lowers the boiling point of water and solvents, allowing for complete evaporation at this gentler temperature without thermally stressing the material.

Deep Pore Cleaning

Simple air drying often leaves moisture trapped in the tiny, capillary-like pores of ceramic powders.

A vacuum creates a pressure differential that physically pulls gas and moisture out of these deep pores.

This is far more effective than forced-air methods, ensuring that the "internal" moisture—not just surface moisture—is evacuated.

Understanding the Trade-offs

Process Time vs. Throughput

While vacuum drying ensures higher quality, it is generally a batch process that may be slower than continuous forced-air drying methods used for less sensitive materials (such as the biomass precursors mentioned in general drying contexts).

It requires a sealed environment, limiting the volume of material that can be processed at once.

Equipment Complexity

Vacuum drying requires maintaining a specific pressure and temperature balance.

If the vacuum seal fails or the pump degrades, moisture removal becomes inconsistent. This adds a layer of maintenance and monitoring that simple convection ovens do not require.

Making the Right Choice for Your Goal

To optimize your Al2O3/PTFE composite manufacturing, align your drying strategy with your performance targets:

- If your primary focus is Mechanical Strength: Prioritize vacuum drying to eliminate micropores, as even small voids can become stress concentration points that lead to fracture.

- If your primary focus is Homogeneity: Ensure the vacuum cycle is long enough to prevent agglomeration, guaranteeing that the Al2O3 disperses evenly within the PTFE without clumping.

Reliable high-performance composites begin with the absolute elimination of moisture before the sintering furnace is ever turned on.

Summary Table:

| Feature | Vacuum Drying (at 80°C) | Standard Atmospheric Drying |

|---|---|---|

| Moisture Removal | Deep pore extraction via pressure differential | Primarily surface-level evaporation |

| Material Integrity | Prevents clumping and ensures free-flowing powder | High risk of particle agglomeration |

| Sintering Outcome | Dense, void-free composite structure | Potential for cracks, pores, and steam defects |

| Thermal Stress | Low (boiling point reduction) | High (requires more heat for same results) |

Elevate Your Composite Manufacturing Precision

Maximize the structural integrity of your Al2O3/PTFE materials with KINTEK’s high-performance vacuum drying solutions. Backed by expert R&D and world-class manufacturing, we provide customizable Vacuum, Muffle, Tube, and CVD systems designed to meet the rigorous demands of lab and industrial high-temperature processes.

Don't let trapped moisture compromise your sintering results. Our specialized equipment ensures uniform heating and deep moisture extraction to eliminate voids and cracks in your final products. Contact KINTEK today to discuss your unique project needs and discover how our advanced furnace technology can optimize your production workflow.

Visual Guide

References

- Guofeng Zhao, Shifan Zhu. Al2O3/PTFE Composites for Marine Self-Lubricating Bearings: Modulation Mechanism of Alumina Particle Size on Material Mechanical Properties and Tribological Behavior. DOI: 10.3390/lubricants13090377

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are vacuum furnaces evolving to meet industrial demands? Scaling Up and Automating for Efficiency

- What critical function does argon gas serve in sintering Ti2AlN ceramics? Ensure Phase Purity and Prevent Oxidation

- Why is a vacuum oven or drying furnace essential for catalyst reuse experiments? Ensure Reliable Recycled Catalyst Data

- How does resistance heating work in vacuum furnace elements? Master Precise Heat Control for Your Lab

- 1200°C Annealing for LPBF Silicon Steel (Fe-Si): Enhancing Soft Magnetic Performance

- How does a vacuum heat treatment furnace compare to traditional heat treatment methods? Discover Precision and Quality Benefits

- What role do laboratory high-temperature furnaces play in the growth of Ni3In2Se2 single crystals? Precision Growth Control

- What materials are suitable for gas quenching in a vacuum furnace? Ideal for High-Hardenability Alloys