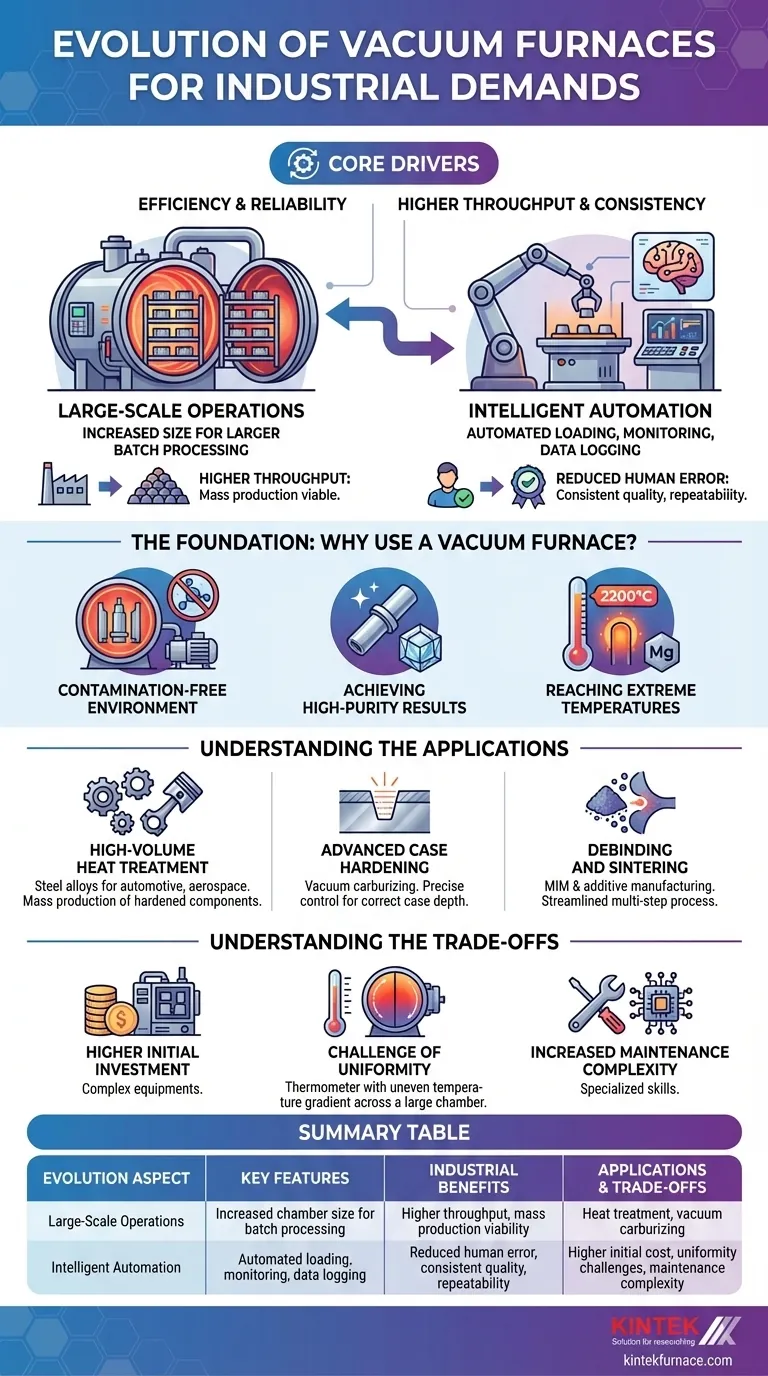

To meet modern industrial demands, vacuum furnaces are primarily evolving in two key directions: increasing in physical size for larger batch processing and incorporating advanced automation. This dual evolution is a direct response to the need for higher throughput, greater product consistency, and reduced operational errors in mass production environments.

The core driver behind vacuum furnace evolution is the industrial pursuit of efficiency and reliability. Moving towards larger, more automated systems allows manufacturers to produce higher quality, contamination-free components at a scale and consistency that is impossible to achieve with manual, small-batch operations.

The Foundation: Why Use a Vacuum Furnace?

A Contamination-Free Environment

The fundamental purpose of a vacuum furnace is to heat materials within a sealed chamber after removing the air. This vacuum environment prevents oxidation and contamination from atmospheric gases like oxygen and moisture.

Achieving High-Purity Results

By eliminating reactive gases, materials can be heat-treated without forming unwanted surface layers. This results in clean, bright, and high-purity components, which is critical for sensitive applications in aerospace, medical, and electronics.

Reaching Extreme Temperatures

Heating elements, often made of molybdenum or tungsten, allow these furnaces to reach exceptionally high temperatures, sometimes exceeding 2200°C. This capability is essential for processing advanced materials, growing crystals, and performing specialized treatments like vacuum carburizing.

The Two Pillars of Modern Evolution

The industry's push for greater efficiency has focused development on two complementary fronts: scale and intelligence.

Driving Towards Large-Scale Operations

The most visible evolution is the move toward large-scale furnaces. As demand for heat-treated components grows, manufacturers require furnaces that can process more parts in a single cycle.

This increase in size directly translates to higher throughput, making mass production economically viable for processes that were once limited to smaller, more specialized applications.

The Rise of Intelligent Automation

Alongside scale, automation is the second critical development. Modern systems automate everything from loading and process monitoring to data logging and unloading.

This reduces reliance on manual operators, minimizing the risk of human error that can lead to inconsistent product quality. Automated process control ensures every batch is treated with the exact same parameters, guaranteeing stability and repeatability.

Understanding the Applications

These evolutionary trends directly support a wide range of industrial processes.

High-Volume Heat Treatment

For steel alloys, large-scale automated furnaces enable the mass production of hardened and tempered components for the automotive and aerospace industries, ensuring every part meets strict quality standards.

Advanced Case Hardening

Processes like vacuum carburizing, which hardens the surface of a component, benefit immensely from automation. Precise control over temperature and gas flow is critical for achieving the correct case depth, and automation delivers this consistency batch after batch.

Debinding and Sintering

In metal injection molding (MIM) and additive manufacturing, furnaces are used for debinding (removing polymer binders) and sintering (fusing metal particles). Large, automated systems streamline this multi-step process for high-volume production.

Understanding the Trade-offs

While beneficial, this evolution is not without its complexities.

Higher Initial Investment

Larger, more automated furnaces represent a significant capital expenditure. The cost of the equipment, facility modifications, and sophisticated control systems is substantially higher than for smaller, manual furnaces.

The Challenge of Uniformity

Ensuring uniform temperature and vacuum levels across a very large chamber is a significant engineering challenge. Any non-uniformity can lead to inconsistent material properties within a single batch, negating some of the benefits of scale.

Increased Maintenance Complexity

Sophisticated automation systems, advanced sensors, and large-scale components require specialized maintenance and troubleshooting skills. Downtime can be more costly and complex to resolve compared to simpler systems.

Making the Right Choice for Your Goal

When evaluating a vacuum furnace, your specific goal should dictate your direction.

- If your primary focus is mass production and throughput: A large-scale, highly automated furnace is the necessary path to achieve industrial-level efficiency.

- If your primary focus is absolute precision and repeatability: Prioritize systems with advanced automation and process control, as this is the key to eliminating variables and ensuring quality.

- If your primary focus is R&D or small, specialized batches: A smaller, more flexible furnace may be more cost-effective and practical, as the overhead of a large automated system may not be justified.

Ultimately, the evolution of vacuum furnaces is about enabling advanced material processing at an industrial scale with unparalleled reliability.

Summary Table:

| Evolution Aspect | Key Features | Industrial Benefits |

|---|---|---|

| Large-Scale Operations | Increased chamber size for batch processing | Higher throughput, mass production viability |

| Intelligent Automation | Automated loading, monitoring, data logging | Reduced human error, consistent quality, repeatability |

| Applications | Heat treatment, vacuum carburizing, debinding, sintering | Enhanced for aerospace, medical, electronics industries |

| Trade-offs | Higher initial cost, uniformity challenges, maintenance complexity | Requires careful investment and skilled upkeep |

Unlock Industrial Efficiency with KINTEK's Advanced Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're scaling up for mass production or prioritizing precision, our furnaces deliver contamination-free results, extreme temperature control, and reliable automation.

Ready to enhance your throughput and consistency? Contact us today to discuss how KINTEK can tailor a solution for your industrial demands!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety