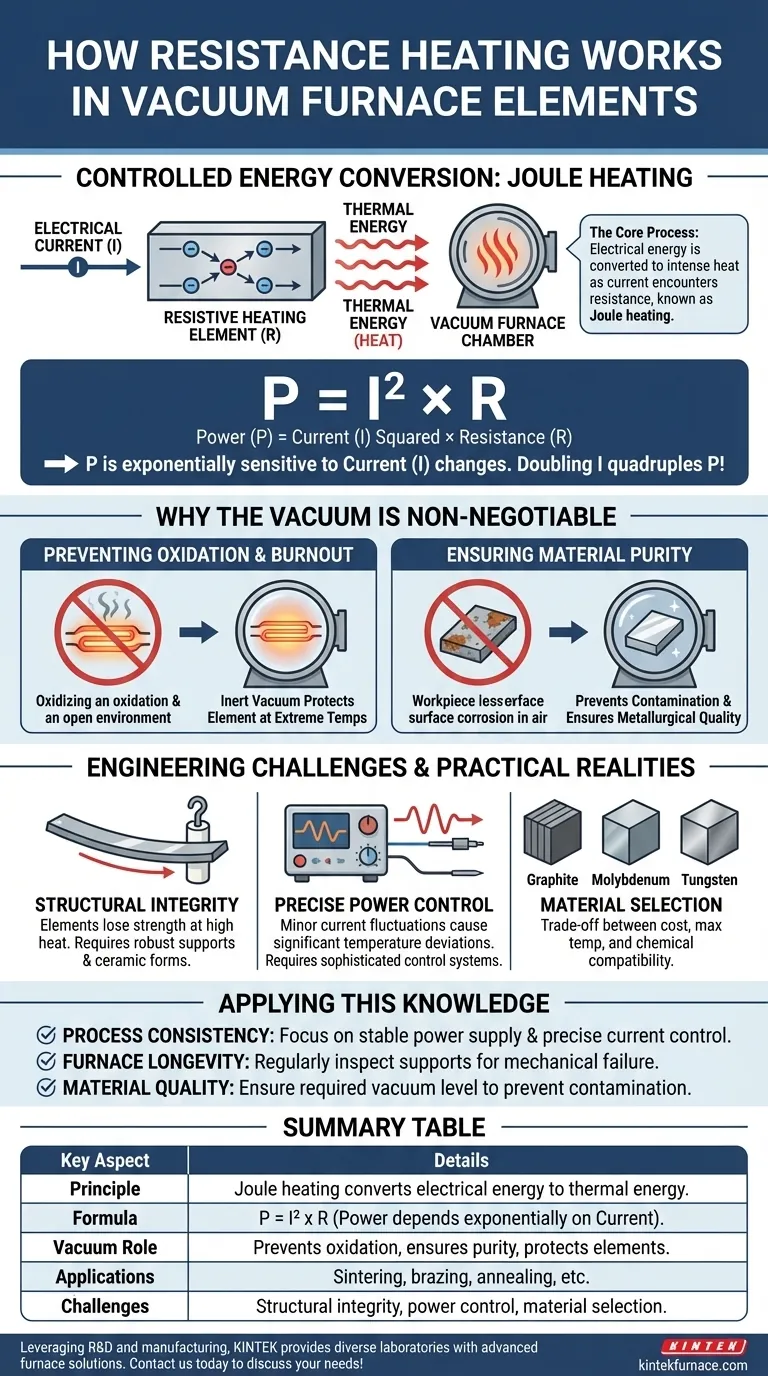

At its core, resistance heating in a vacuum furnace is a process of controlled energy conversion. An electrical current is forced through a heating element material that is specifically designed to resist the flow of electricity. This resistance causes the element to heat up intensely, a phenomenon known as Joule heating, which then radiates thermal energy to the workpiece within the furnace's oxygen-free environment.

The fundamental challenge is not just generating heat, but doing so at extreme temperatures without the heating element destroying itself or contaminating the material being processed. The vacuum provides the protective, inert environment necessary for the resistance heating principle to be effective.

The Fundamental Principle: Joule Heating

Resistance heating operates on a simple but powerful principle of physics. Understanding this is key to understanding your furnace's behavior.

From Electrical Energy to Thermal Energy

When a voltage is applied across a heating element, it forces electrons to move through the material, creating an electrical current. The element's material is chosen for its high electrical resistance, which acts like friction against this flow of electrons.

As electrons collide with the atoms of the resistor material, they transfer their kinetic energy. This energy transfer causes the atoms to vibrate more intensely, which we perceive and measure as heat.

The Power of the Formula: P = I² x R

The amount of heat generated, or power (P), is defined by the equation P = I² x R. Here, 'I' represents the current and 'R' represents the resistance of the element.

This formula reveals a critical insight: power is exponentially more sensitive to changes in current (I) than it is to changes in resistance (R). Doubling the current quadruples the heat output, making precise current control the most important factor for regulating temperature.

Why a Vacuum is Non-Negotiable

Generating intense heat is only half the battle. Doing so in a controlled manner requires a vacuum environment for several critical reasons.

Preventing Oxidation and Burnout

Heating elements, often made of materials like graphite or molybdenum, operate at temperatures that would cause them to instantly oxidize—or simply burn up—if exposed to oxygen.

By removing the air from the furnace chamber, the vacuum eliminates the oxygen and other reactive gases. This creates an inert atmosphere that protects the heating element from rapid degradation, allowing it to reach and sustain very high temperatures.

Ensuring Material Purity

The vacuum environment is equally important for the workpiece itself. It prevents unwanted chemical reactions on the surface of the material being heat-treated, such as oxidation or nitriding.

This ensures the metallurgical and chemical purity of the final product, which is critical in applications like sintering, brazing, and annealing advanced materials.

Understanding the Trade-offs and Practical Realities

While the principle is straightforward, its application involves significant engineering challenges and trade-offs.

The Challenge of Structural Integrity

At extreme operating temperatures, heating elements lose structural strength and can begin to sag, warp, or become brittle over time.

To counteract this, elements must be carefully supported. They are often suspended by robust ceramic or alloy hooks and hangers or placed within rigid ceramic form tiles to maintain their shape and prevent electrical shorts.

The Importance of Power Control

Because heat output is so sensitive to current, even minor fluctuations in the power supply can lead to significant temperature deviations. This can compromise the quality of the heat treatment process.

This is why vacuum furnaces rely on sophisticated temperature control systems. These systems use thermocouples to monitor temperature and constantly adjust the power output to maintain a stable and precise thermal profile.

Material Selection is Key

The choice of heating element material is a trade-off between cost, maximum operating temperature, and chemical compatibility. Materials like graphite are cost-effective for many processes, while tungsten and molybdenum are used for higher-temperature applications where carbon contamination is a concern.

Applying This Knowledge in Practice

Understanding how resistance heating works empowers you to better control your processes and troubleshoot your equipment.

- If your primary focus is process consistency: Focus on the stability of your power supply, as precise current control is the most direct way to ensure repeatable thermal cycles.

- If your primary focus is furnace longevity: Regularly inspect the element supports for signs of cracking or sagging, as mechanical failure is a common issue at high temperatures.

- If your primary focus is material quality: Ensure your system achieves and holds the required vacuum level to prevent even trace amounts of oxygen from contaminating your parts.

By grasping these core principles, you can move from simply operating the equipment to truly mastering the thermal process.

Summary Table:

| Key Aspect | Details |

|---|---|

| Principle | Joule heating converts electrical energy to thermal energy via resistance in elements. |

| Formula | P = I² x R, where power depends on current and resistance. |

| Vacuum Role | Prevents oxidation, ensures material purity, and protects elements. |

| Applications | Sintering, brazing, annealing in labs requiring high-temperature precision. |

| Challenges | Structural integrity at high temps, precise power control, material selection. |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Enhance your lab's efficiency and achieve superior results with our tailored solutions — contact us today to discuss your needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control